Thick paste quick-drying type weather-resistant and wear-resistant coating for wind turbine blades and preparation method thereof

A technology for wind power blades and wear-resistant coatings, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of low utilization rate of painting workshops, slow drying speed at room temperature, large blade volume, etc., and achieve drying speed. The effect of fast, excellent weather resistance and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

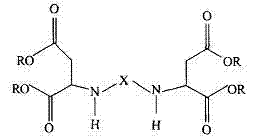

Method used

Image

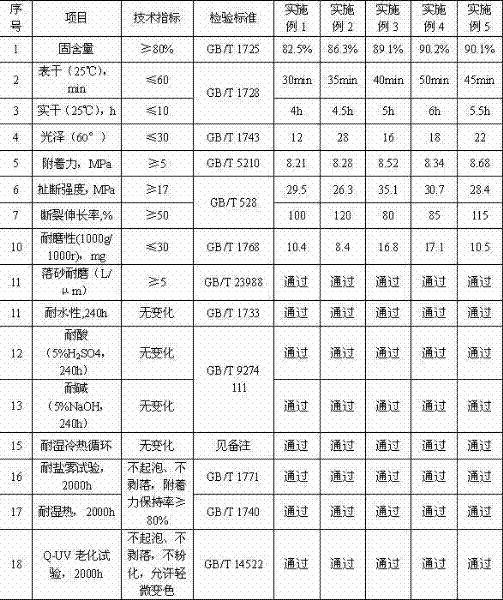

Examples

Embodiment 1

[0070] A: NH1420 50

[0071] NH1520 10.5

[0072] BYK-220S 0.8

[0073] EFKA4061 1.2

[0074] Fumed silica 1

[0075] Molecular sieve 1

[0076] Titanate coupling agent TC-101 2

[0077] Rutile titanium dioxide 15

[0080] OK520 6

[0081] TINUVIN 384 0.1

[0082] Hydroxy-containing fluorine-modified siloxane with a molecular weight of 200 2.1

[0083] BYK-354 0.25

[0084] Airex 900 0.05

[0085] Xylene 2

[0086] Butyl acetate 2

[0087] Propylene glycol methyl ether acetate 1

[0088] B: 3090 resin 40

[0089] 1,2,6 Hexatriol 7

[0090] HDI 30

[0091] Nano silica 2.89

[0092] Silane coupling agent KH550 0.1

[0093] Triethylenediamine 0.01

[0094] Cyclohexanone 10

[0095] Propylene glycol methyl ether acetate 10

[0096] The preparation method is:

[0097] 1. Group A:

[0098] 1) Take the required amount of polyaspartic acid ester and add it to the dispersion tank. The diluent is a mixture of xyle...

Embodiment 2

[0106] A: NH1420 41

[0107] NH1520 18

[0108] AT-203 0.4

[0109] EFKA4050 0.4

[0110] Polyethylene wax 1.2

[0111] Ketimine 1.3

[0112] Silane coupling agent KH560 1

[0113] Rutile titanium dioxide 9.5

[0114] Sunfast Scarlet 0.5

[0117] PERGOPAK M2 3

[0118] TINUVIN 1130 1

[0119] Hydroxy-modified polysiloxane with a molecular weight of 100 0.1

[0120] BYK-355 0.1

[0121] Airex 910 0.5

[0122] Xylene 2

[0123] Butyl acetate 2

[0124] Propylene glycol methyl ether acetate 3

[0125] B: T1136 resin 60

[0126] Pentaerythritol 5

[0127] IPDI 15

[0128] Nano alumina 1.5

[0129] Silane coupling agent KH560 0.4

[0130] Dibutyltin dilaurate 0.1

[0131] Cyclohexanone 9

[0132] Propylene glycol methyl ether acetate 9

[0133] The preparation method of component A is the same as in Example 1.

[0134] The preparation method of component B is:

[0135] Mix T1136 resin, pentaerythritol, cyclohex...

Embodiment 3

[0139] A: NH1420 31

[0140] NH1520 30

[0141] BYK-163 0.4

[0142] EFKA4060 0.8

[0144] Aldimine 1.1

[0145] Silane coupling agent KH570 0.5

[0146] Rutile titanium dioxide 10.5

[0147] Phthalo blue 0.5

[0149] Mica powder 4

[0150] OK412 3.5

[0151] TINUVIN 328 0.2

[0152] Hydroxyl-modified polysiloxane with a molecular weight of 50 0.19

[0153] BYK-356 0.2

[0154] Fomex N 0.01

[0155] Xylene 3

[0156] Butyl acetate 3

[0157] Propylene glycol methyl ether acetate 4

[0158] B: MX353 resin 30

[0159] Trimethylolpropane 20

[0160] h 12 MDI 28.45

[0161] Nano Titanium Dioxide 10

[0162] Silane coupling agent KH570 1.5

[0163] Cobalt naphthenate 0.05

[0164] Cyclohexanone 5

[0165] Propylene glycol methyl ether acetate 5

[0166] The preparation method of component A is the same as in Example 1.

[0167] The preparation method of component B is:

[0168] Mix MX353 resin, trimethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com