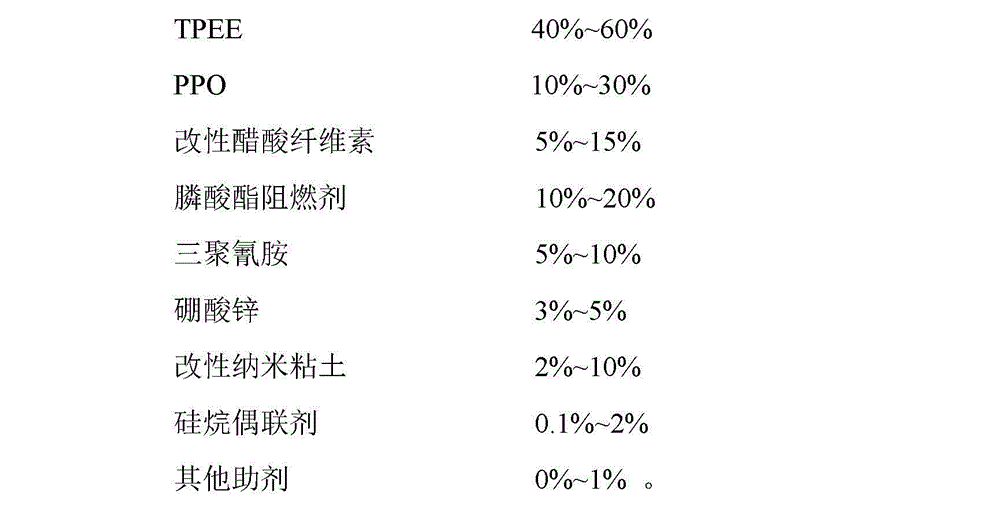

Novel halogen-free flame-retardant thermoplastic polyester elastomer (TPEE) and preparation method thereof

A thermoplastic elastomer and modification technology, applied in the field of halogen-free flame retardant TPEE thermoplastic elastomer and its preparation, achieves the effects of simple and easy process, strong hydrolysis resistance and good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Pretreatment of additives: The raw material TPEE (provided by China Textile Investment Development Co., Ltd.) was vacuum-dried at 100°C for 4 hours to obtain dry TPEE for use. After mixing cellulose (provided by Changzhou Lirdton New Material Technology Co., Ltd.) and acetic acid (analytical grade, Wuxi Jingke Chemical Co., Ltd.) at a mass-to-volume ratio (g:mL) of 1:3, the Acetylation in N-methyl-N-propenylmorpholine quaternary ammonium salt ionic liquid, wherein the mass volume ratio (g:mL) of cellulose to N-methyl-N-propenylmorpholine quaternary ammonium salt ionic liquid is 1:300, stir in a high-speed mixer at 60°C for 4 hours to obtain modified cellulose acetate for later use. The degree of acetylation of the obtained modified cellulose acetate is greater than 50%, and the degree of acetylation can be measured by measuring the ester value or alcohol content. Judgment, the specific method can refer to GB / T 14455.8-1993. Will D 98 Nanoclay in the range of 100-9...

Embodiment 2

[0030] (1) Pretreatment of additives: The raw material TPEE (provided by China Textile Investment Development Co., Ltd.) was vacuum-dried at 120°C for 2 hours to obtain dry TPEE for use. After mixing cellulose (provided by Changzhou Lirdton New Material Technology Co., Ltd.) and acetic acid (analytical grade, Wuxi Jinke Chemical Co., Ltd.) at a ratio of 1:4 by mass to volume (g:mL), the Acetylation in N-methyl-N-propenylmorpholine quaternary ammonium salt ionic liquid, wherein the mass volume ratio (g:mL) of cellulose to N-methyl-N-propenylmorpholine quaternary ammonium salt ionic liquid is 1:500, stir in a high-speed mixer at 80°C for 2 hours to obtain modified cellulose acetate for later use. The degree of acetylation of the obtained modified cellulose acetate is greater than 50%, and the degree of acetylation can be measured by measuring the ester value or alcohol content. Judgment, the specific method can refer to GB / T 14455.8-1993. Will D 98 Nanoclay in the range of 100...

Embodiment 3

[0034] (1) Pretreatment of additives: The raw material TPEE (provided by China Textile Investment Development Co., Ltd.) was vacuum-dried at 110°C for 3 hours to obtain dry TPEE for use. After mixing cellulose (provided by Changzhou Lirdton New Material Technology Co., Ltd.) and acetic acid (analytical grade, Wuxi Jingke Chemical Co., Ltd.) at a mass-to-volume ratio (g:mL) of 1:5, the Acetylation in chloroaluminate triethylamine hydrochloride ionic liquid, wherein the mass volume ratio (g:mL) of cellulose to chloroaluminate triethylamine hydrochloride ionic liquid is 1:400, mixed at 70°C at high speed Stir in the machine for 3 hours to obtain modified cellulose acetate for later use. The degree of acetylation of the obtained modified cellulose acetate is greater than 50%. The degree of acetylation can be judged by measuring the ester value or alcohol content. For specific methods, please refer to GB / T 14455.8 -1993. Will D 98 The nanoclay in the range of 100~900nm (provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com