High-strength binding band and production method thereof

A manufacturing method and high-strength technology, applied in the field of strapping and its manufacturing, can solve the problems of increased cost, high difficulty in controlling the process, insignificant improvement in strength and impact toughness, etc. Good toughness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

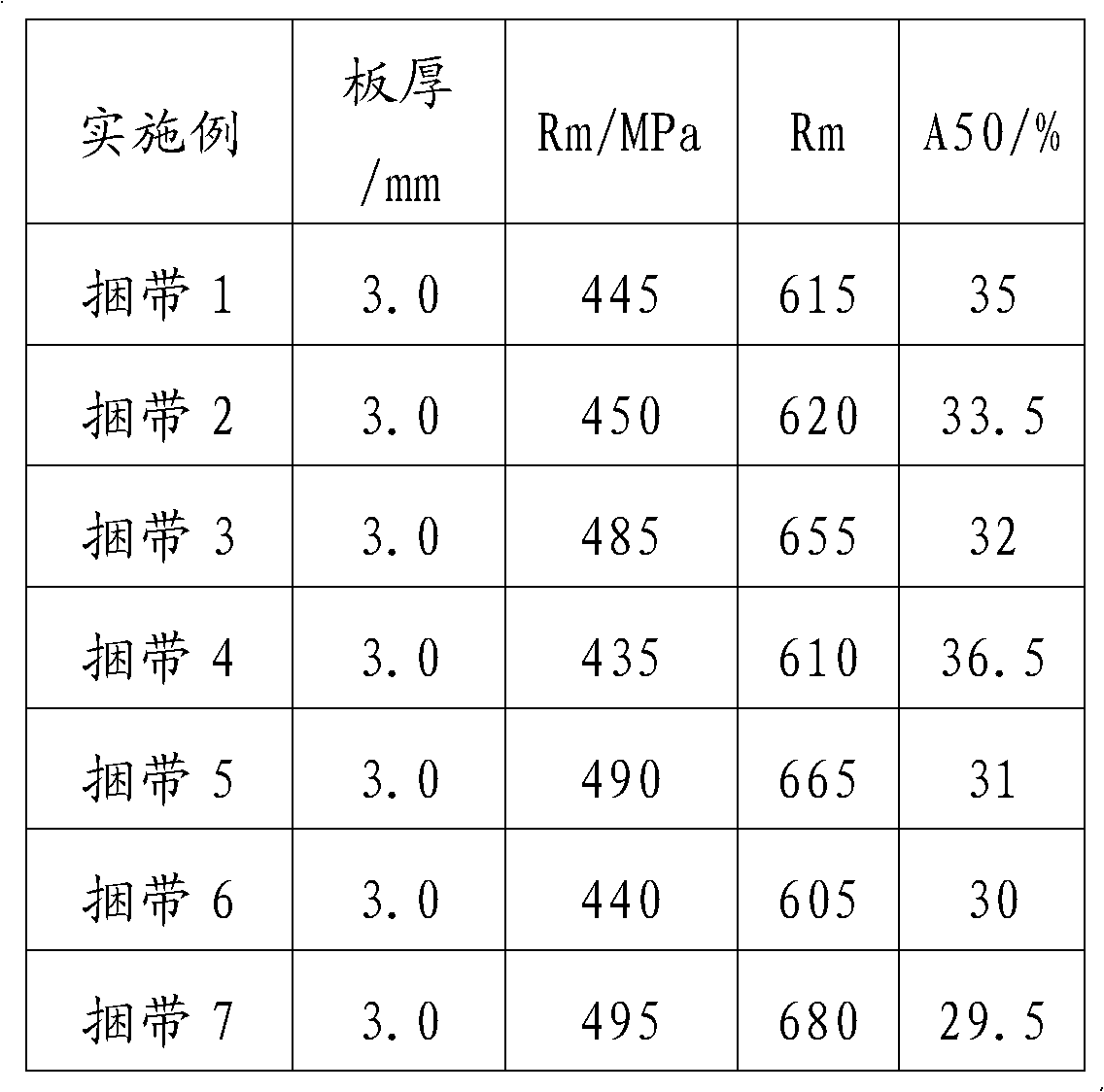

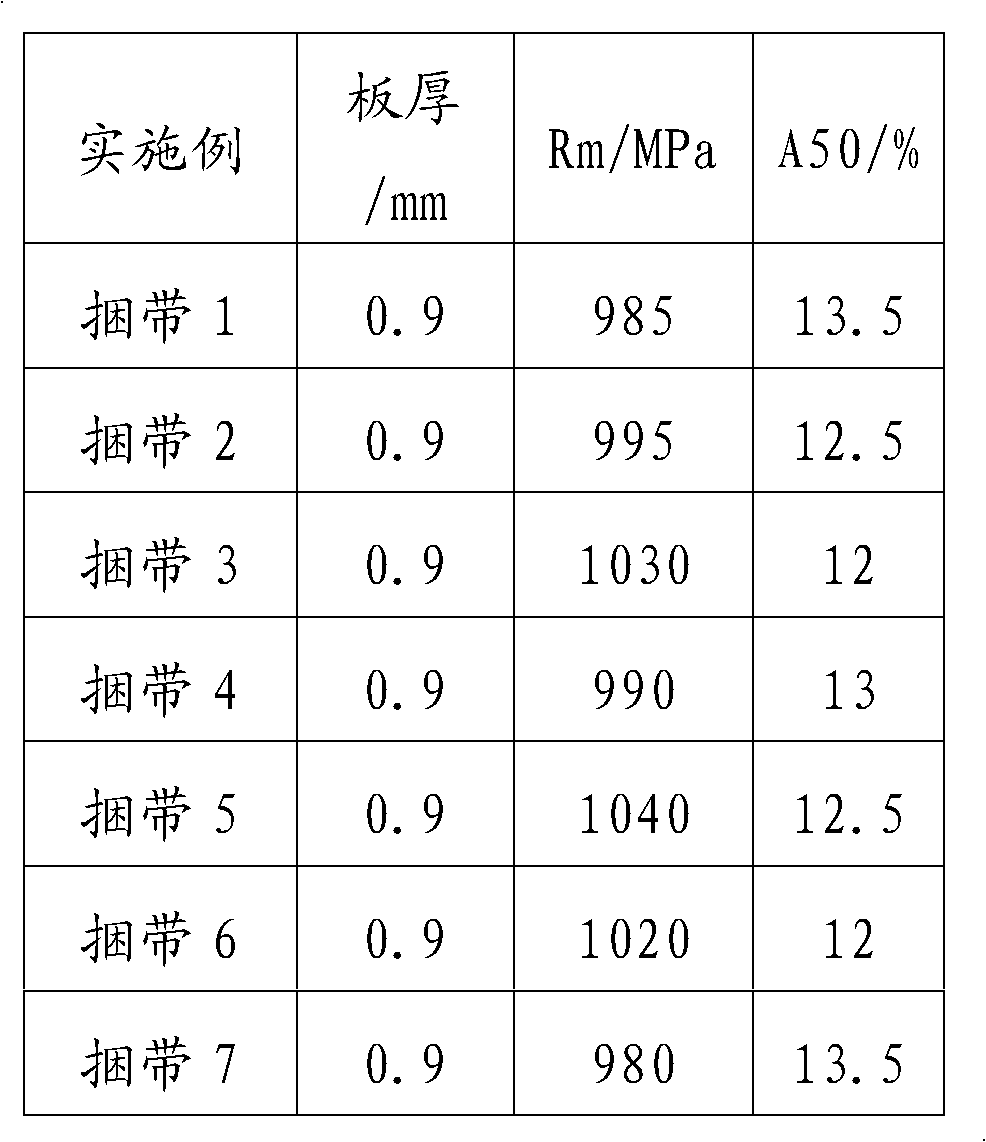

Embodiment 1

[0028] According to the composition requirements of the steel of the present invention, the chemical composition is as in Example 1 in Table 1. Hot metal steelmaking: smelting in a 250-ton oxygen top-bottom double-blown converter, then undergoing RH vacuum treatment for 15 minutes, and feeding Ca-Si wire through LHF ladle furnace to denature inclusions, and feeding CaSi wire into the ladle furnace The amount of molten iron is 700 grams per ton, and the feeding speed is 300m / min; hot rolling: the reheating temperature of the steel billet in the rolling process is 1250°C, the final rolling temperature is 800°C, the coiling temperature is 550°C, and the cooling rate is 15°C / s; cold rolling : cumulative reduction rate 90%; blueing annealing: blueing annealing temperature of high temperature blueing furnace is 550°C, temperature of lead bath furnace is 500°C, belt speed is 5.5m / min, the mechanical properties of the finished strapping are shown in Table 3 1. The thickness of the ho...

Embodiment 2

[0030] According to the composition requirements of the steel of the present invention, the chemical composition is as in Example 2 in Table 1. Hot metal steelmaking: the steel of the present invention is smelted on a 250-ton oxygen top-bottom double-blown converter, subjected to RH vacuum treatment for 25 minutes, and fed with Ca-Si wire through an LHF ladle furnace to denature inclusions, and then fed into the ladle furnace The amount of feeding into the CaSi line is 800 grams per ton of molten iron, and the wire feeding speed is 250m / min; hot rolling: the reheating temperature of the billet during the rolling process is 1200°C, the final rolling temperature is 950°C, the coiling temperature is 800°C, and the cooling rate is 30°C / s The cumulative reduction rate of cold rolling is 80%; the blueing annealing temperature of the high-temperature blueing furnace is 500°C, the temperature of the lead bath furnace is 460°C, and the belt speed is 5m / min. The thickness of the rolled ...

Embodiment 3

[0032] According to the steel composition requirements of the present invention, the chemical composition is as in Example 3 in Table 1. Hot metal steelmaking: the steel of the present invention is smelted on a 250-ton oxygen top-bottom double-blown converter, subjected to RH vacuum treatment for 30 minutes, and fed with Ca-Si wire through an LHF ladle furnace to denature inclusions, and then fed into the ladle furnace The amount of feeding into the CaSi line is 750 grams per ton of molten iron, and the feeding speed is 270m / min; hot rolling: the reheating temperature of the billet during the rolling process is 1300°C, the final rolling temperature is 750°C, the coiling temperature is 450°C, and the cooling rate is 5°C / s The cumulative reduction rate of cold rolling is 40%; the blueing annealing temperature of the high-temperature blueing furnace is 450°C, the temperature of the lead bath furnace is 550°C, and the belt speed is 5m / min. The thickness of the rolled steel strip i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com