37Mn5 steel and production technology thereof

A technology of production process and process, which is applied in the field of 37Mn5 steel and its production process, can solve the problems that cannot meet the needs of thin-walled pipe production, cracks on the surface of thin-walled pipes, and high folding of pipes, and achieve simple processes and non-metallic inclusions. The effect of less content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

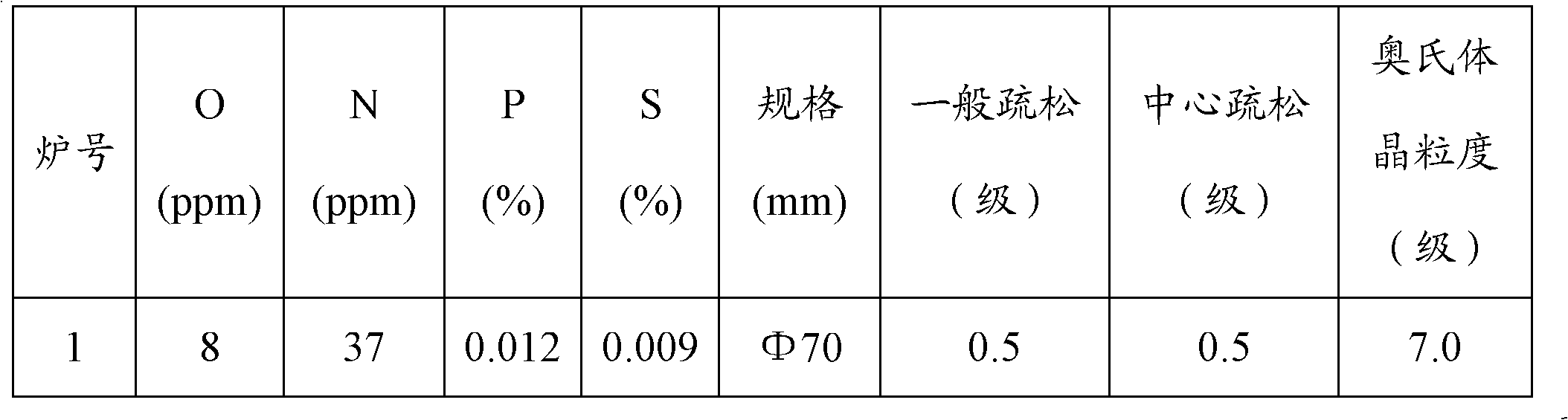

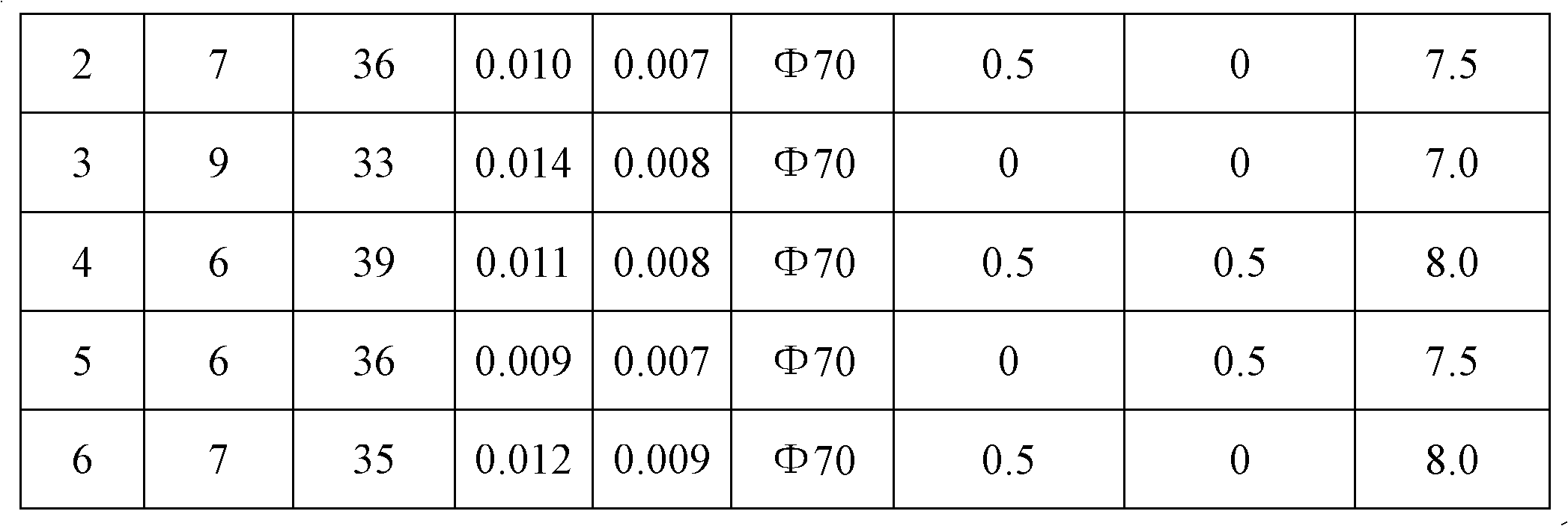

[0050] Synchronous production of 6 furnaces of 37Mn5 steel by the following processes:

[0051] (1) Converter process: ensure a hit rate at the end point, avoid back blowing, and control the carbon at the end point at 0.10%; the converter adopts the sliding plate slag blocking process; the double slag method is used to control the phosphorus content of molten steel.

[0052] (2) Refining process: LF refining treatment time is 20 minutes; strengthen the effect of deoxidation and removal of inclusions. It is required that the refining slag has a basicity of 2.5, FeO in the slag is 1%, and the white slag is kept for 15 minutes. After refining, the bottom blowing and argon soft blowing time is guaranteed to be 10 minutes, so as to facilitate the removal of inclusions in molten steel.

[0053] (3) Continuous casting process: Ladle and tundish are used for protective casting and sealed with argon blowing. The crystallizer adopts submerged nozzle + mold slag to realize full protection ...

Embodiment 2

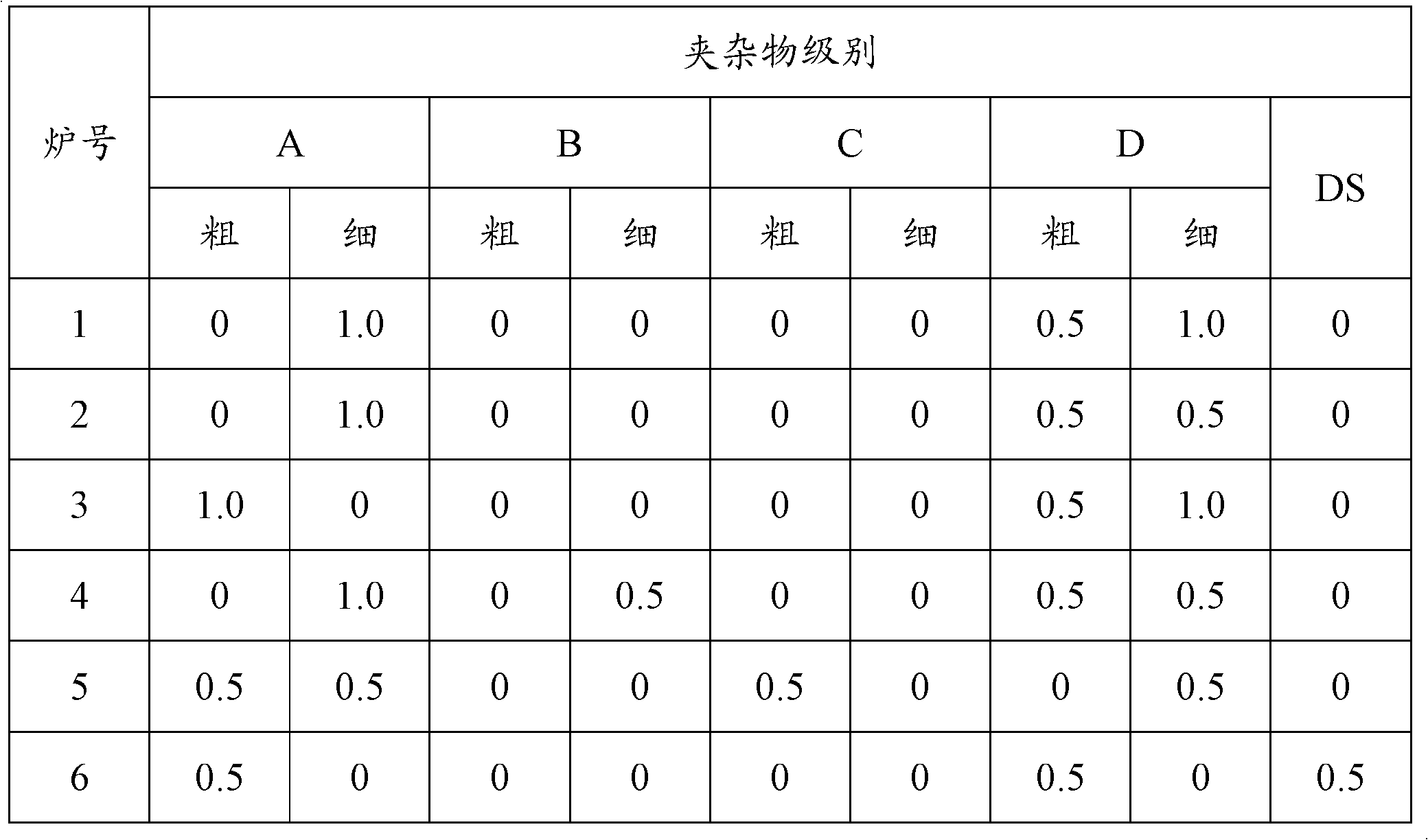

[0064] 37Mn5 steel is produced by the following process:

[0065] (1) Converter process: ensure a hit rate at the end point, avoid back blowing, and control the carbon at the end point at 0.05%; the converter adopts the sliding plate slag blocking process; the double slag method is used to control the phosphorus content of molten steel.

[0066] (2) Refining process: LF refining treatment time is 15 minutes; strengthen deoxidation and de-inclusion effects. It is required that the refining slag has a basicity of 2.0, FeO in the slag is 2%, and the white slag is kept for 10 minutes. After refining, the bottom blowing and argon soft blowing time is guaranteed to be 10 minutes, so as to facilitate the removal of inclusions in molten steel.

[0067] (3) Continuous casting process: Ladle and tundish are used for protective casting and sealed with argon blowing. The mold adopts submerged nozzle + mold powder to realize full protection casting without oxidation; casting temperature: t...

Embodiment 3

[0071] 37Mn5 steel is produced by the following process:

[0072] (1) Converter process: ensure one-time end-point hit rate, avoid back blowing, and control the end-point carbon at 0.08%;

[0073] (2) Refining process: LF refining treatment time 18min; strengthen deoxidation and de-inclusion effects. It is required that the refining slag has a basicity of 2.2, FeO in the slag is 1.5%, and the white slag is kept for 13 minutes. After refining, the bottom blowing and argon soft blowing time is guaranteed to be 8 minutes to facilitate the removal of inclusions in molten steel.

[0074] (3) Continuous casting process: Ladle and tundish are used for protective casting and sealed with argon blowing. The mold adopts submerged nozzle + mold powder to realize full protection casting without oxidation; casting temperature: the superheat of the tundish is at 25°C; Mold liquid level braking control and electromagnetic stirring; mold mold slag is used to ensure the surface quality of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com