Preparation method of hard alloy/high-chromium alloy-based wear-resistant composite material

A cemented carbide and high-chromium alloy technology, used in metal processing equipment, manufacturing tools, casting and molding equipment, etc., can solve the problems of large residual stress, increased residual stress, limited use range, etc., to achieve small residual stress at the interface, The effect of small heat affected zone and large controllable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

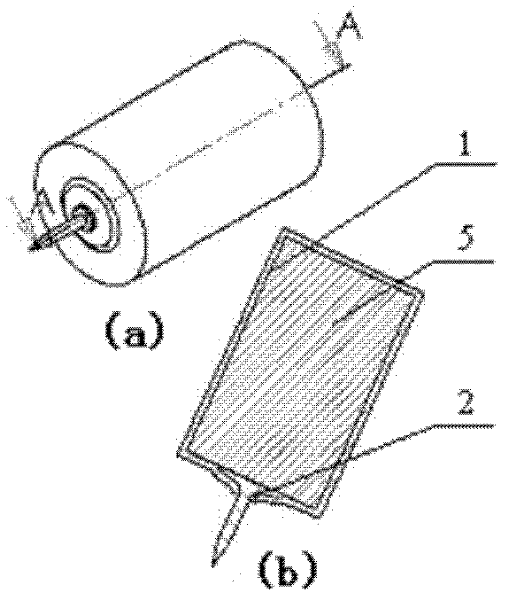

[0024] Taking the preparation of ZGM110 type (output: 5 ~ 8t / h, grinding disc diameter: 1100mm, rotating speed: 50r / min, power: 110KW) coal mill lining tile as an example, and in conjunction with the accompanying drawings, the present invention is further explained. : 5~8t / h, disc diameter: 1100mm, speed: 50r / min, power: 110KW.

[0025] A preparation method of cemented carbide / high chromium alloy-based wear-resistant composite material, comprising the following steps:

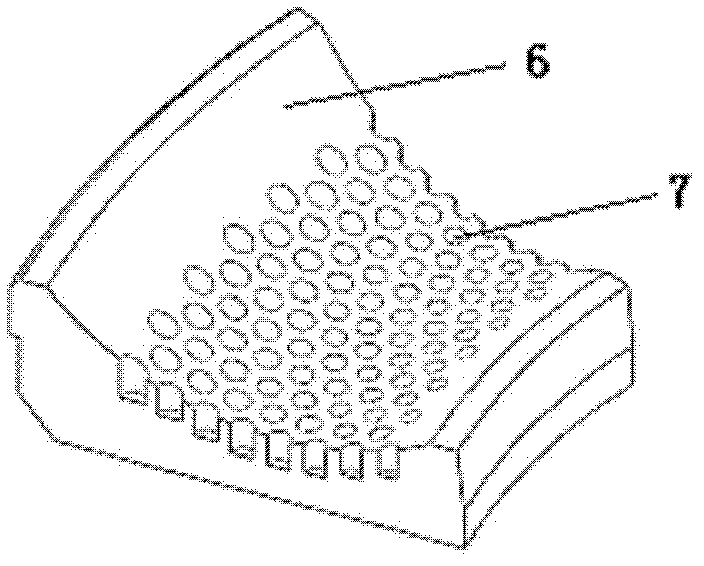

[0026] Step 1: Carbide waste is cut and processed into a composite material reinforcement of the required shape and size, and the cemented carbide of the YG8 grade is selected, and processed into a cemented carbide reinforcement with a size of Φ5mm×8mm through wire cutting, except Sand blasting after oiling, and finally cleaning,

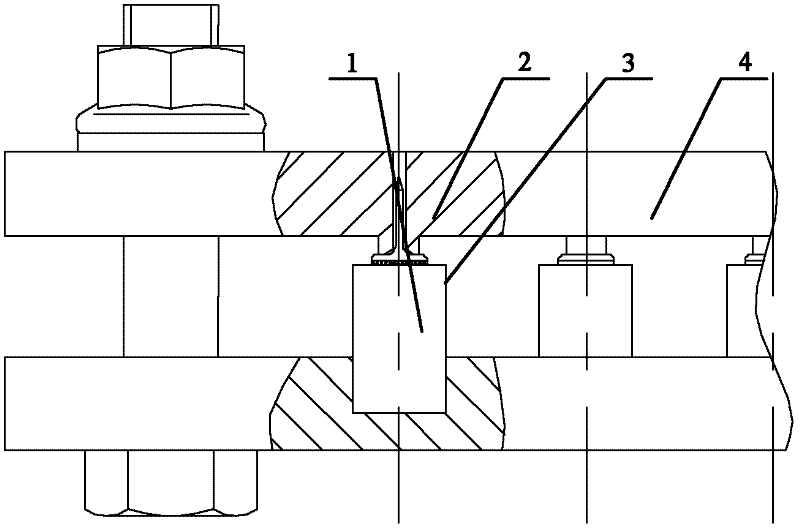

[0027] Step 2, welding an iron nail to one end of the cemented carbide reinforcement treated in step 1, the welding adopts a vacuum brazing process, and the brazing material is sele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com