Preparation method of yttrium aluminum garnet yellow fluorescent powder for white light LED

A technology of yttrium aluminum garnet type and yellow phosphor, which is applied in chemical instruments and methods, luminescent materials, and the use of gas discharge lamps. Effects of preventing particle agglomeration, excellent luminous performance, and short synthesis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

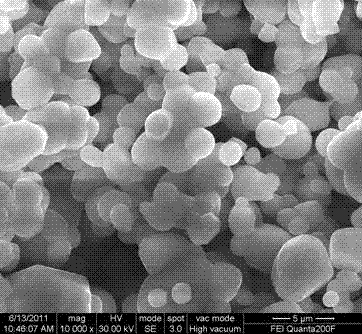

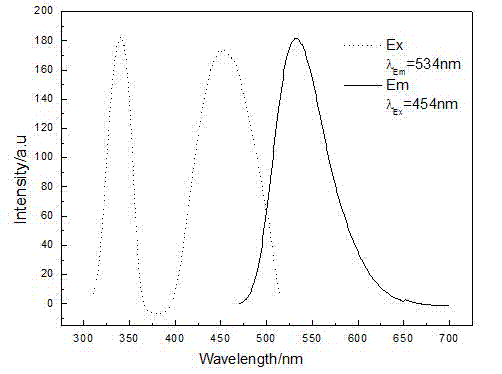

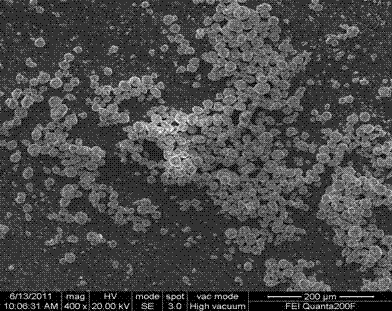

Image

Examples

Embodiment 1

[0036] Weigh out 0.0258 g CeO 2 , placed in 20 ml of 1:1 nitric acid solution, added dropwise 5 ml of 30% hydrogen peroxide, heated and stirred until completely dissolved, then weighed 0.3375 g Al powder and 0.8306 g Y 2 O 3 , added to it, heated and dissolved to obtain a mixed solution of nitrates. Add 1.0440 g KF and 1.8600 g ethylene glycol to the mixed solution obtained above, heat and stir to dissolve it, and concentrate it to a nearly viscous state, then put it in a microwave oven to heat and ignite, and the combustion product is put into a mixture of nitrogen and hydrogen. Mixed gas (H 2 : 5 V%) in a tubular atmosphere furnace at 1100 °C for 120 min. The heat-treated product is washed, dried, ground and sieved to obtain Y 2.94 Al 5 O 12 : 0.06 Ce 3+ phosphor.

Embodiment 2

[0038] Weigh out 0.0258 g CeO 2 , placed in 20 ml of 1:1 nitric acid solution, added dropwise 5 ml of 30% hydrogen peroxide, heated and stirred until completely dissolved, then weighed 0.3375 g Al powder and 0.8306 g Y 2 O 3 , added to it, heated and dissolved to obtain a mixed solution of nitrates. Add 1.053 g NaCl and 1.8600 g ethylene glycol to the mixed solution obtained above, heat and stir to dissolve it, and concentrate it to a nearly viscous state, then put it in a microwave oven to heat and ignite, and the combustion product is put into a mixture of nitrogen and hydrogen. Mixed gas (H 2 : 5 V%) in a tubular atmosphere furnace at 1100 °C for 120 min. The heat-treated product is washed, dried, ground and sieved to obtain Y 2.94 Al 5 O 12 : 0.06 Ce 3+ phosphor.

Embodiment 3

[0040] Weigh out 0.0258 g CeO 2 , placed in 20 ml of 1:1 nitric acid solution, added dropwise 5 ml of 30% hydrogen peroxide, stirred while heating until completely dissolved, and then weighed 0.975g of Al(OH) 3 and 0.8306 g Y 2 O 3 , added to it, heated and dissolved to obtain a mixed solution of nitrates. Add 1.0440 g KF and 2.5000 g glycine to the mixed solution obtained above, heat and stir to dissolve it, and concentrate it to a nearly viscous state, then put it into a microwave oven to heat and ignite, and the combustion product is put into a mixed gas of nitrogen and hydrogen. (H 2 : 5 V%) in a tubular atmosphere furnace at 1100 °C for 120 min. The heat-treated product is washed, dried, ground and sieved to obtain Y 2.94 Al 5 O 12 : 0.06 Ce 3+ phosphor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com