Preparation method of composite film on surface of metallic material and solution composition for preparation method

A metal material and surface composite technology, which is applied in the field of metal materials, can solve problems such as difficult industrial application, inability to process shapes, and weak bonding force of the film layer, and achieve the effects of increased bonding strength, low cost, and improved bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The present invention is a kind of preparation method of metal material surface composite membrane layer and its solution composition, and its method step is:

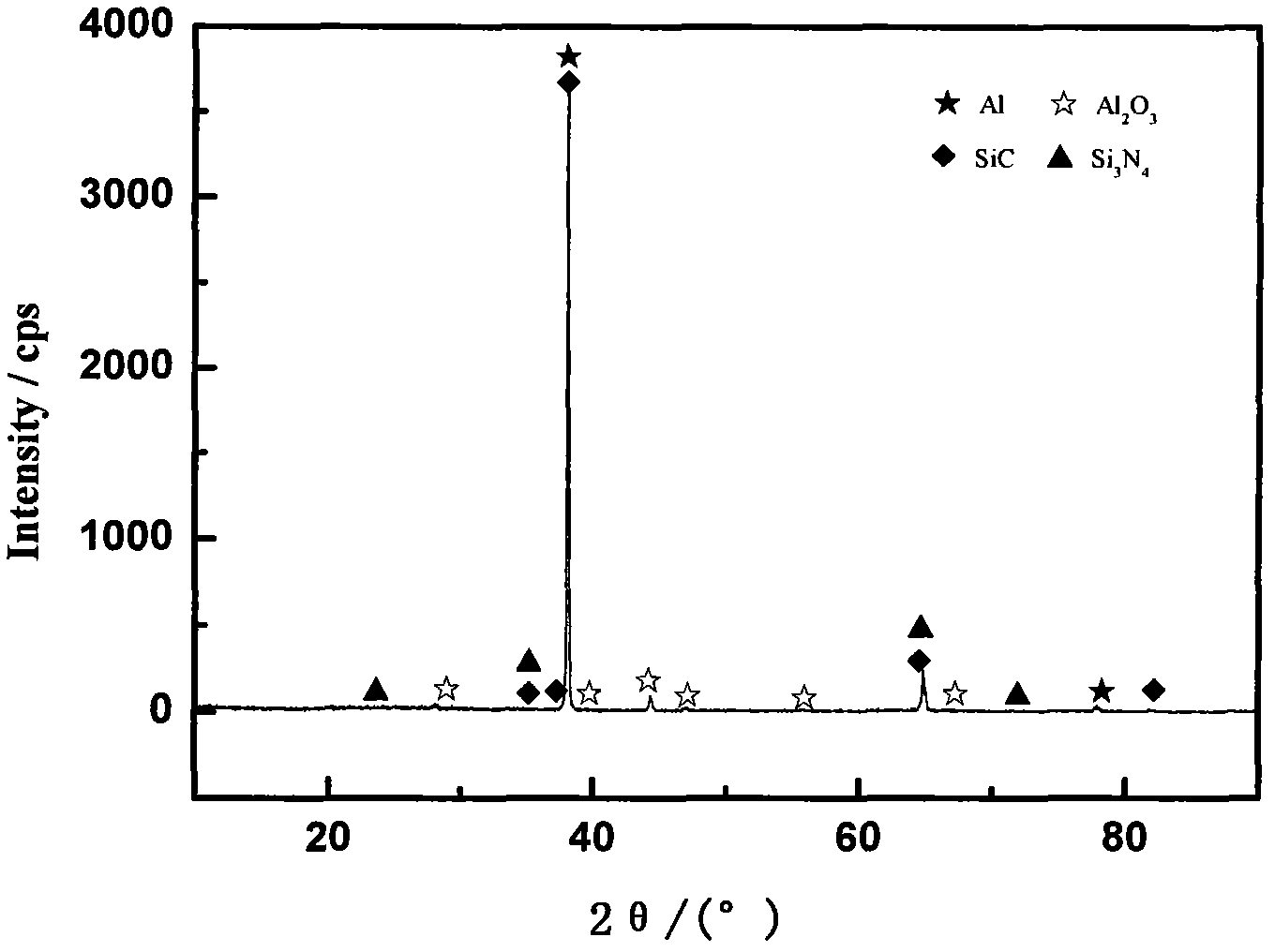

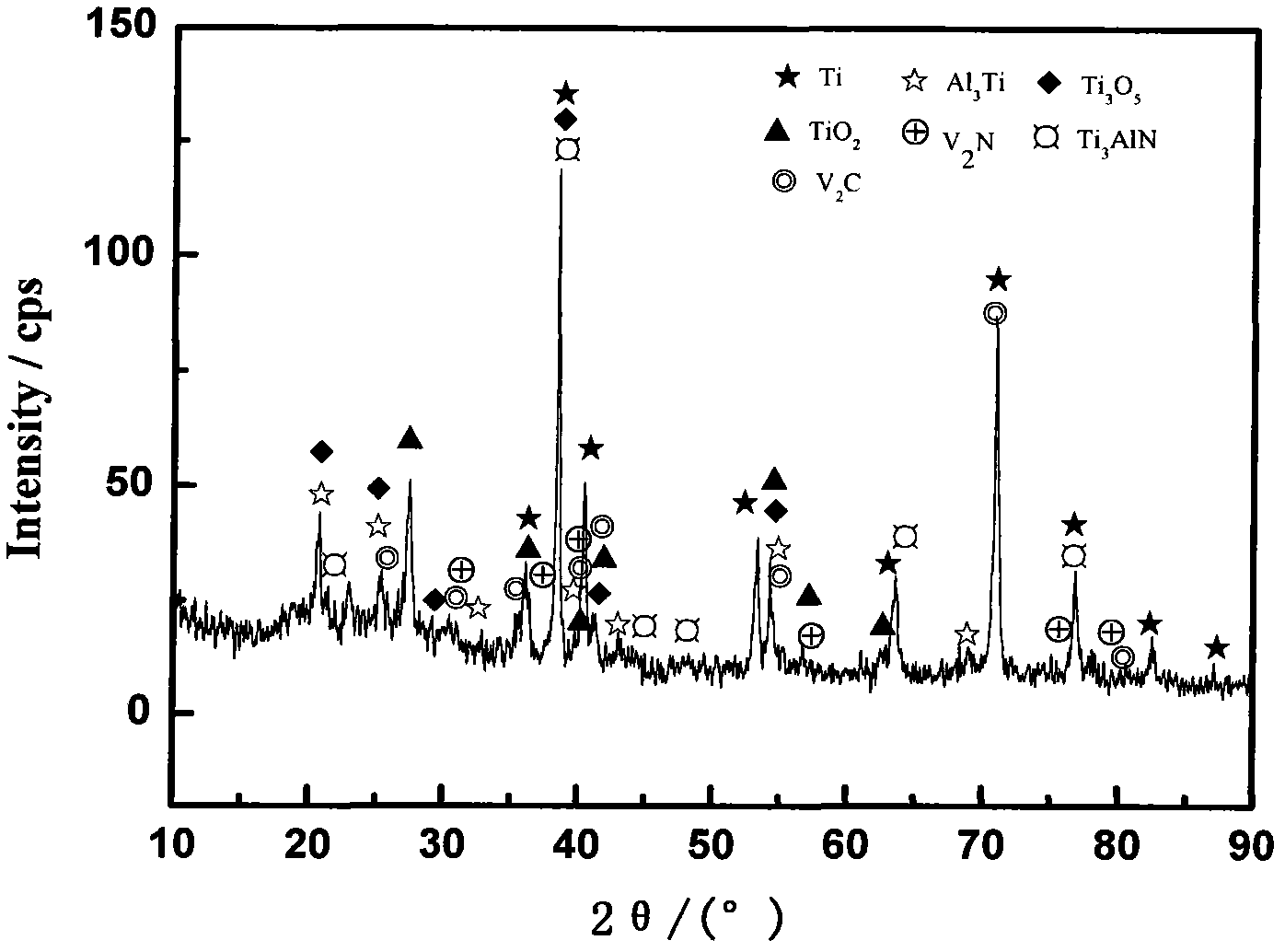

[0017] (1) Place the polished and cleaned metal workpiece in the electrolyte solution containing the elements to be infiltrated and first perform plasma electrolytic infiltration treatment, and form a surface modification layer containing the distribution of infiltrated elements on its surface;

[0018] (2) After the workpiece to be processed is cleaned, it is placed in an alkaline electrolyte for plasma electrolytic oxidation treatment, and finally a composite film with high hardness, corrosion resistance, wear resistance and friction reduction is obtained on the surface of the workpiece. Floor.

[0019] The metal material treated by this method is magnesium alloy, or aluminum alloy, or titanium alloy, or steel.

[0020] When performing plasma electrolytic infiltration treatment, connect the metal workpiece to...

Embodiment 1

[0026] The processed sample is cast AZ91D magnesium alloy, which is cut into discs with specifications of

[0027] The specific operation steps are:

[0028] 1. Sample pretreatment: The sample was polished with 400-mesh, 800-mesh, and 1500-mesh sandpaper in sequence, and washed with distilled water.

[0029] 2. The sample is first subjected to plasma electrolysis osmosis treatment: the sample is connected to the power electrode, placed in a solution composed of formamide 20ml / L, sodium hydroxide 2g / L, control voltage: 200V, frequency: 600HZ, duty cycle 50 %, the processing time is 30min.

[0030] 3. The sample is subjected to plasma electrolytic oxidation treatment: After the sample is treated with plasma electrolytic infiltration, it is cleaned with distilled water, connected to the anode of the power supply, and placed in a composition composed of sodium silicate 25g / L, sodium aluminate 7g / L, and sodium hydroxide 2g. / L, in a solution of potassium fluoride 20g / L. Contro...

Embodiment 2

[0032] The processed sample is cast AZ91D magnesium alloy, which is cut into discs with specifications of

[0033] The specific operation steps are:

[0034] 1. Sample pretreatment: The sample was polished with 400-mesh, 800-mesh, and 1500-mesh sandpaper in sequence, and washed with distilled water.

[0035] 2. The sample is first subjected to plasma electrolytic osmosis treatment: the sample is connected to the power electrode, placed in a solution composed of formamide 50ml / L, thiourea 40g / L, and sodium hydroxide 5g / L, control voltage: 330V, frequency: 700HZ, duty cycle 20%, processing time 50min.

[0036]3. The sample is subjected to plasma electrolytic oxidation treatment: After the sample is treated with plasma electrolytic infiltration, it is cleaned with distilled water, connected to the anode of the power supply, and placed in a composition composed of sodium silicate 15g / L, sodium molybdate 5g / L, and sodium tungstate 7g / L, potassium hydroxide 6g / L, potassium fluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com