Method for preparing high-performance tin phosphorus bronze band

A technology of high-performance tin-phosphorus and bronze strips, which is applied in the field of direct cold blanking to produce high-performance tin-phosphorus bronze strips, can solve problems such as increasing production costs, reducing yield, and no obvious improvement in regional segregation, and achieves product quality and The effect of high yield, reduced casting internal stress, and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

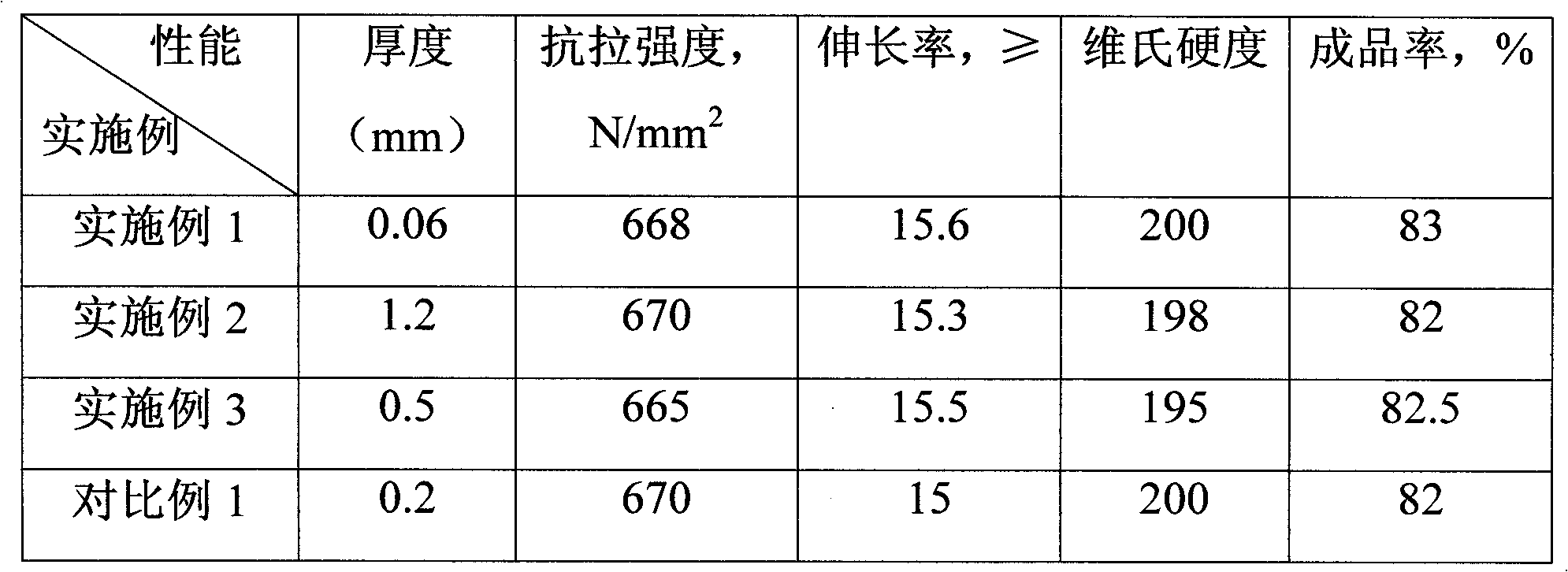

Examples

Embodiment 1

[0021] Production and production of C5102 brand bronze, hard state, strip material with a specification of 0.2×150mm, the ratio of tin, phosphorus and copper is adjusted to make a furnace charge of 4.5% tin, 0.03% phosphorus, and the balance copper.

[0022] Put the furnace material into the melting furnace, melt the furnace material in the atmosphere and raise the temperature to 1180°C, stir and remove the slag for sampling and analysis using a direct-reading spectrometer for analysis, and transfer the ingredients to the holding furnace after the ingredients meet the formula ratio. The temperature of the copper liquid in the holding furnace is 1140°C. The liquid surface of the holding furnace is covered with dry rice bran, and then samples are taken for analysis, and the composition is adjusted. After the composition meets the formula ratio, horizontal continuous casting is carried out. The casting temperature is 1180°C. Pushing the 2.5mm process, the casting speed is 178mm / mi...

Embodiment 2

[0025] Production of C5102 brand bronze, hard state, strip material with a specification of 0.2×150mm, the proportion of tin, phosphorus and copper is adjusted to make a furnace charge of 5.5% tin, 0.05% phosphorus, and the balance copper.

[0026] Put the furnace material into the melting furnace, melt the furnace material in the atmosphere and raise the temperature to 1240 °C, stir the slag for sampling and analysis, and use a direct-reading spectrometer for analysis. The ingredients meet the formula ratio and then transfer to the holding furnace. The temperature of the copper liquid in the holding furnace is 1200°C, and the liquid surface of the holding furnace is covered with dry rice bran, and then samples are taken for analysis, and the composition is adjusted. After the composition meets the formula ratio, horizontal continuous casting is carried out. The casting temperature is 1200°C. Push the 1.6mm process, the casting speed is 160mm / min, the strip outlet temperature i...

Embodiment 3

[0029] Production and production of C5102 brand bronze, hard state, strip material with a specification of 0.2×150mm, the proportion of tin, phosphorus and copper is adjusted to make a furnace charge of 5.0% tin, 0.35% phosphorus, and the balance copper.

[0030] Put the furnace material into the melting furnace, melt the furnace material in the atmosphere and raise the temperature to 1180°C, stir and remove the slag for sampling and analysis using a direct-reading spectrometer for analysis. The ingredients meet the formula ratio and then transfer to the holding furnace. The temperature of the copper liquid in the holding furnace is 1140°C. The liquid surface of the holding furnace is covered with dry rice bran, and then samples are taken for analysis, and the composition is adjusted. After the composition meets the formula ratio, horizontal continuous casting is carried out. The casting temperature is 1140°C. Push the 3.2mm process, the casting speed is 190mm / min, the strip ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com