Sound absorbing paper material and manufacturing method thereof

A manufacturing method and paper material technology, applied in the field of sound-absorbing materials, can solve the problems of human environment and air pollution, unsatisfactory sound-absorbing performance, and narrow application of materials, and achieve good market competitiveness, good fireproof and self-extinguishing characteristics, Small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

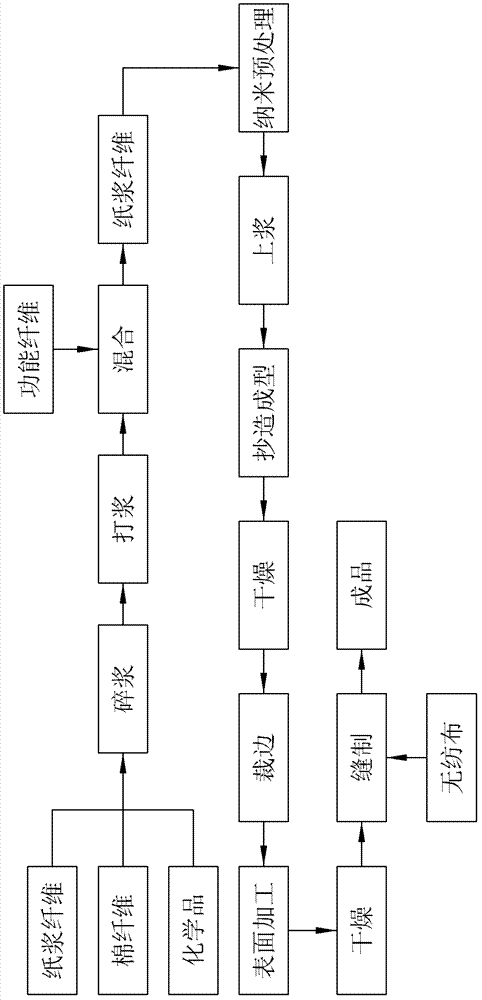

[0073] The manufacturing method of sound-absorbing paper material is as follows:

[0074] (1) Dry the main fiber material at 100°C for 2 hours before manufacturing.

[0075](2), the dried main fiber material and auxiliary material are put into the blender and stirred; wherein, by weight percentage, the formula of the main fiber material is 28% plant fiber, and the auxiliary material formula is 45% cotton fiber , 20% elastic nanocellulose and 7% functional polymer fibers (polyester fiber, polypropylene fiber, aramid fiber weight ratio is 1: 1.2: 2.5).

[0076] (3) During the material mixing process, the chemicals that need to be added are 0.5% flame retardant, 3% water repellent, and 1% preservative, which account for the weight of the dry main fiber material. / min speed stirring evenly.

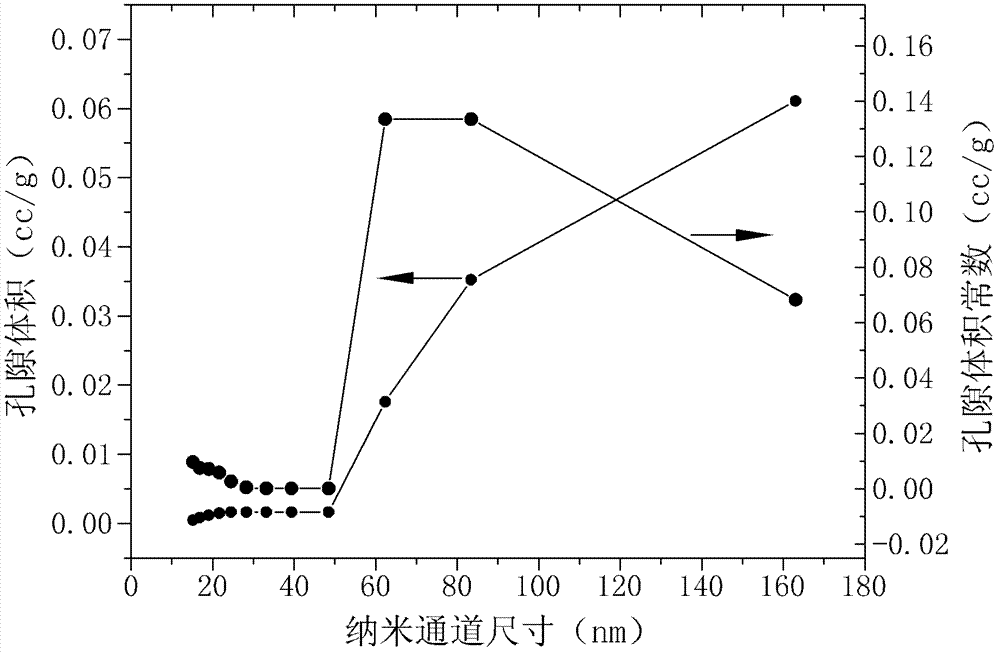

[0077] (4), the manufacture method of elastic nano cellulose: common paper pulp or plant cotton fiber are first dissolved (1-butyl-3-methylimidazolium chloride salt) condition at room tempe...

no. 2 example

[0086] The manufacturing method of sound-absorbing paper material is as follows:

[0087] (1) Dry the main fiber material at 100°C for 2 hours before manufacturing.

[0088] (2), the dried main fiber material and auxiliary material are put into the blender and stirred; wherein, by weight percentage, the formula of the main fiber material is 70% plant fiber, and the auxiliary material formula is 30% Cotton fiber.

[0089] (3) During the material mixing process, the chemicals that need to be added are 2% flame retardant, 3% water repellent, and 3% preservative, which account for the weight of the dry main fiber material. / min speed stirring evenly.

[0090] (4), the manufacture method of elastic nano cellulose: common paper pulp or plant cotton fiber are first dissolved (1-butyl-3-methylimidazolium chloride salt) condition at room temperature (dissolving temperature is 80 ℃, dissolving time After 1 hour), the elastic nanocellulose with higher elasticity made by spinning in wa...

no. 3 example

[0099] The manufacturing method of sound-absorbing paper material is as follows:

[0100] (1) Dry the main fiber material at 105°C for 2 hours before manufacturing.

[0101] (2), the dried main fiber material and auxiliary material are put into the blender and stirred; wherein, by weight percentage, the formula of the main fiber material is 28% plant fiber, and the auxiliary material formula is 45% Cotton fibers, composed of 27% elastane nanocellulose.

[0102] (3) During the material mixing process, the chemicals that need to be added are 1.5% flame retardant, 8% water repellent, 2% preservative, and 300 rpm in the mixer. / min speed stirring evenly.

[0103] (4), the manufacture method of elastic nano cellulose: common paper pulp or plant cotton fiber are first dissolved (1-butyl-3-methylimidazolium chloride salt) condition at room temperature (dissolving temperature is 80 ℃, dissolving time After 1 hour), the elastic nanocellulose with higher elasticity made by spinning i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com