Non-vacuum casting and forming method of chromium zirconium copper alloy plate for continuous casting crystallizer

A continuous casting crystallizer and forming processing technology, which is applied in the field of non-ferrous metal alloy smelting and processing, can solve the problems of low production efficiency, product specification restrictions, high production costs, etc., and achieve the effect of improving production efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, the chemical composition (wt%) of the chromium-zirconium-copper alloy is: Cr 1.0%, Zr 0.45%, Mg 0.02%, rare earth element La 0.05%, and the rest is copper.

[0027] The non-vacuum smelting and processing molding method of the chromium-zirconium copper alloy plate for the continuous casting crystallizer of the present embodiment is carried out according to the following steps:

[0028] 1. First make CuCr and CuZr master alloys from easily oxidized elements such as Cr and Zr, and use them as raw materials added later;

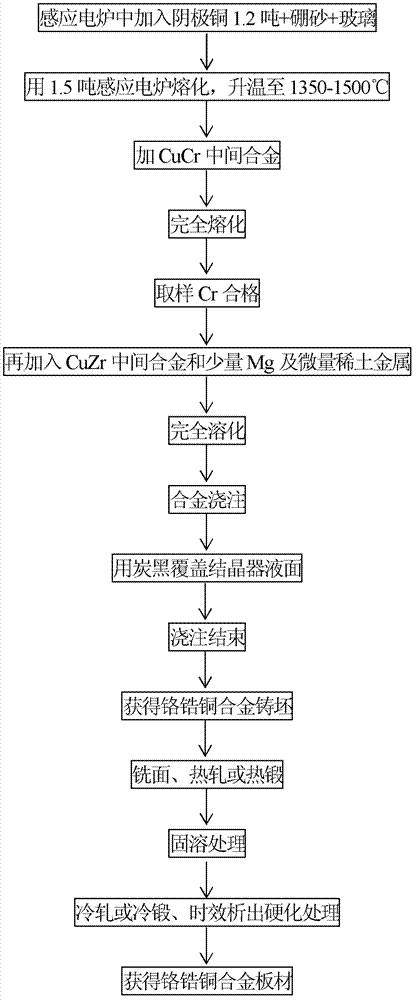

[0029] 2. If figure 1 As shown, select 1.2 tons of standard cathode copper that meets the quality requirements, join in 1.5 tons of intermediate frequency induction furnace, add a sufficient amount of dehydrated borax and glass as covering agent at the same time, here, the weight ratio of dehydrated borax and glass is set to 3: 1. Melt the cathode copper. Among them, the covering agent is covered on the copper melt to avoid direct con...

Embodiment 2

[0031] The difference from Example 1 is that in this example, the chemical composition (wt%) of the chromium-zirconium copper slab is: Cr0.82%, Zr0.015%, Mg0.012%, rare earth element La0.01%, and the rest for copper.

[0032] Among them, the processing rate of hot rolling or hot forging is controlled at 55%; cold rolling or cold forging adopts three-pass small processing rate (processing rate is controlled at 25%); the solution treatment temperature is 850°C, and the aging precipitation hardening temperature is 400°C .

[0033] In the present embodiment, the physical property test value of this plate is: σ b =545MPa, σ s =443MPa, δ=32%, HB=129, conductivity 87% IACS.

Embodiment 3

[0035] The difference from Example 1 is that in this example, the chemical composition (wt%) of the chromium-zirconium copper slab is: Cr0.99%, Zr0.02%, Mg0.01%, rare earth element Ce0.04%, the rest for copper.

[0036] Among them, the processing rate of hot rolling or hot forging is controlled at 65%; cold rolling or cold forging adopts five-pass small processing rate (processing rate is controlled at 30%); the solution treatment temperature is 800°C, and the aging precipitation hardening temperature is 500°C .

[0037] In the present embodiment, the physical property test value of this plate is: σ b =565MPa, σ s =462MPa, δ=30%, HB=132, conductivity 84% IACS.

[0038] The results show that the present invention solves the problems of complex process, high production cost and low production efficiency in the existing vacuum melting and casting process, and the input cost of the non-vacuum melting and casting equipment is only about 1 / 10 of the vacuum furnace melting and cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com