Production equipment and method of center riveting type copper-steel composite contact line

A technology of copper-steel compounding and production methods, applied in the field of wire rods, can solve problems such as potential safety hazards, copper-steel detachment, etc., and achieve the effects of eliminating voids, saving electrical conductivity, and overcoming detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

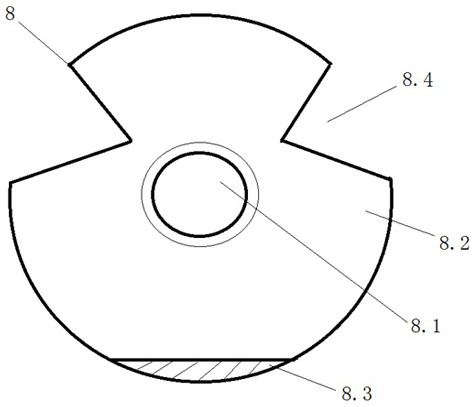

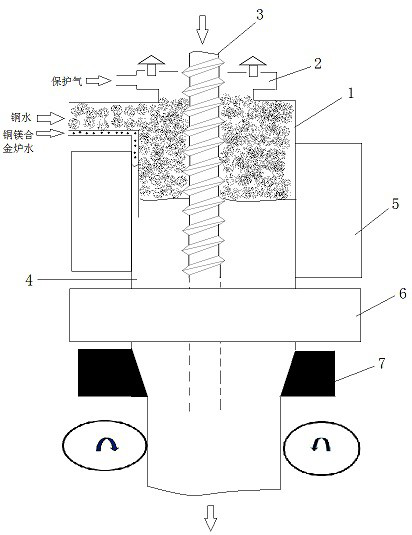

[0031] See figure 1 and image 3 , image 3 A structural diagram of a production equipment of a central riveted copper steel composite contact line is drawn. As shown, the production apparatus of the central riveted copper steel composite contact line according to the present invention includes a first mold 1, a second mold 4, a continuous cold forging device 6, and a finishing mold 7.

[0032] The first mold 1 is provided with a steel pole inlet 2, and both sides of the steel pole inlet 2 are provided with a regulating valve. On the side of the steel pole inlet 2, a protective gas entry is provided, and the protective gas is transferred. On the one hand, it is Impurities of the metal surface, the second is to remove oxides on the surface of the threaded steel rod, including iron oxides, and the third is to remove the surface of the surface, is isolated, isolated, so as to avoid the composite forming shape as the threaded steel rod enters the cavity.

[0033] The first mold 1 includ...

Embodiment 2

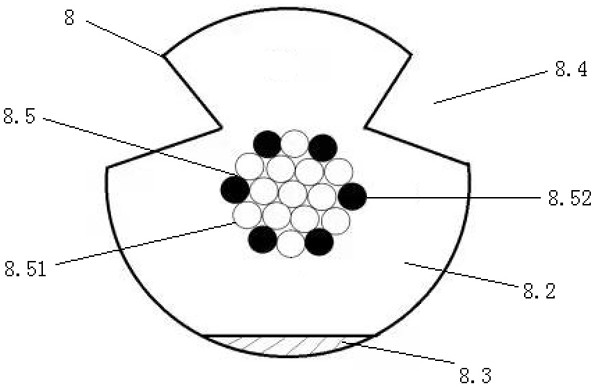

[0055] See figure 2 , figure 2 A structural diagram of the contact line of Example 2 of the present invention is plotted. As shown, in the present embodiment, in this embodiment 2, the composite copper steel strand 8.5 is used instead of the threaded steel core 8.1, the composite copper steel stranded pair 8.5 includes a central monofilament and a center monofilament. Multi-layer peripheral single line, the center monofilament is steel wire 8.51, each peripheral single line comprising spaced wire 8.51 and copper wire 8.52.

[0056] The peripheral single line is not less than two layers.

[0057] The composite copper strand 8.5 after entering the copper chamber, the melting point of copper is 1083 ° C, the melting point of the steel, the temperature of the copper water is as high as 1200 ° C, and the copper wire 8.52 of the composite copper steel strand 8.52 is melted, melted. After that, the copper water in the copper cavity is filled with a gap melting of the copper wire 8.52, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com