Production equipment and method of mortise and tenon type high-strength and high-conductivity copper-steel composite contact wire

A technology of copper-steel compounding and production methods, which is applied in the direction of casting molding equipment, metal processing equipment, and other manufacturing equipment/tools, can solve problems such as potential safety hazards, copper-steel detachment, etc., to increase service life, save electrical conductivity, and promote The effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] see Figure 1-5 , Figure 5 A schematic diagram of the production equipment for a mortise and tenon type high-strength and high-conductivity copper-steel composite contact wire is drawn. As shown in the figure, the production equipment for mortise and tenon type high-strength and high-conductivity copper-steel composite contact wire involved in the present invention includes a mortise and tenon steel rod production device and a copper-steel composite contact wire production device. The mortise and tenon steel rod production device includes steel Rod mould, circulating cooling system and finishing mould, the steel rod mold is equipped with a steel cavity, the inner wall of the steel cavity is provided with a plurality of grooves, the steel cavity is connected with the molten steel melting furnace to inject molten steel, and the steel rod mold is connected with the finishing mold after passing through the circulating cooling system Connected, the circulating cooling syst...

Embodiment 2

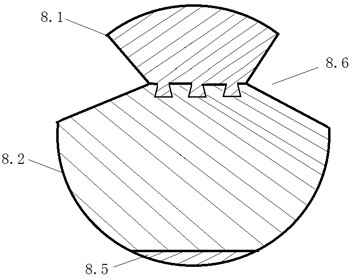

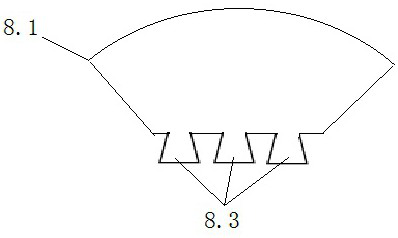

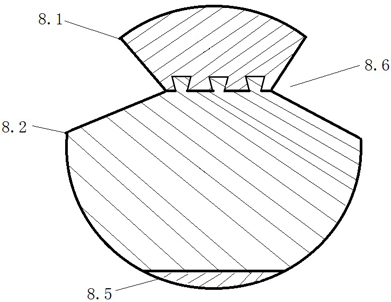

[0058] see Figure 3-Figure 4 , image 3 A schematic diagram of the structure of the contact wire in Example 2 is drawn. As shown in the figure, the production equipment and method of a mortise and tenon type high-strength and high-conductivity copper-steel composite contact wire involved in this embodiment 2 is different from that of embodiment 1 in that the steel layer 8.1 is in contact with the copper layer 8.2 The inner side of the copper layer 8.2 is provided with a plurality of sockets 8.4, and the inner side of the copper layer 8.2 in contact with the steel layer 8.1 is provided with a plurality of falcon bars 8.3, which match with the upper socket 8.4, so that the steel layer A mortise and tenon connection structure is formed between 8.1 and copper layer 8.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com