Thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and elastomer technology, which is applied in the field of polymer compounds and its preparation, can solve problems such as static mixers or filling machines are easy to block, TPU melt MI changes too much, and product quality in the production process is affected. Good color, uniform molecular weight distribution, and high recovery times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

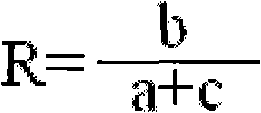

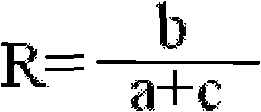

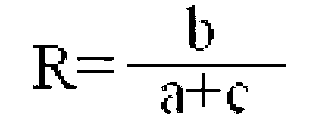

Image

Examples

Embodiment 1-4 and comparative example 1-2

[0028] Embodiment 1-4 and comparative example 1-2 adopt following raw material and auxiliary agent:

[0029] PTMEG1000 polytetrahydrofuran ether glycol, Mitsubishi, Japan, molecular weight 1000;

[0030] PBA 1000 Polyadipate-1,4-butylene glycol ester diol, Taiwan Yongchun, molecular weight 1000;

[0031] PBA 2000 Polyadipate-1,4-butylene glycol ester diol, Taiwan Yongchun, molecular weight 2000;

[0032] MDI 4,4-diphenylmethane diisocyanate, Japan NOU, molecular weight 250.26;

[0033] BDO 1,4-butanediol, Mitsubishi Chemical, molecular weight 90.12;

[0034] Dabco T-9 stannous octoate, gas chemical industry;

[0035] Irganox1010 tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, Ciba Specialty Chemicals;

[0036] Irgafos168 tris(2,4-di-tert-butylphenyl) phosphite, Ciba Specialty Chemicals;

[0037] Tinuvin 329 2-(2′-hydroxy-5′-tertoctylphenyl)benzotriazole, Ciba Specialty Chemicals;

[0038] Tinuvin 292 bis(1,2,2,6,6-pentamethyl-4-piperid...

Embodiment 1

[0042] Component A uses PTMEG1000, the organic diisocyanate is MDI, and the small molecule diol is BDO. Heat them to 90°C, 60°C, and 45°C respectively, and add 20ppm of DABCO to A component T-9, 0.2wt% Irganox1010, 0.2wt% Irgafos168, 0.4wt% Tinuvin 329, 0.4wt% Tinuvin292, 0.4wt% Licowax C.

[0043] The above three components are introduced into the twin-screw pre-mixing unit with a temperature of 160°C and a speed of 400rpm through a metering pump and a flow meter at a ratio of 53.0wt%, 37.9wt%, and 9.1wt%, respectively, and then the temperature is 200°C, extruded by a reactive twin-screw extruder with a rotation speed of 200rpm, and finally synthesized thermoplastic polyurethane elastomer particles by underwater pelletizing.

Embodiment 2

[0045] Component A uses PBA1000, the organic diisocyanate is MDI, and the small molecule diol is BDO. Heat them to 90°C, 60°C, and 45°C respectively, and add 20ppm of DABCO to the A component T-9, 0.2wt% Irganox1010, 0.2wt% Irgafos168, 0.4wt% Tinuvin 329, 0.4wt% Tinuvin292, 0.4wt% Licowax C, 0.3wt% Staboxol P100.

[0046] The above three components are introduced into the twin-screw premixing unit at a temperature of 160°C and a speed of 400rpm through a metering pump and a flowmeter at a ratio of 53.0wt%, 37.9wt%, and 9.1wt%, respectively, and then passed through a temperature of 200 °C, extruded by a reactive twin-screw extruder with a rotational speed of 200rpm, and finally pelletized under water to synthesize thermoplastic polyurethane elastomer particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com