Barium strontium calcium titanate pyroelectric ceramic material and preparation method thereof

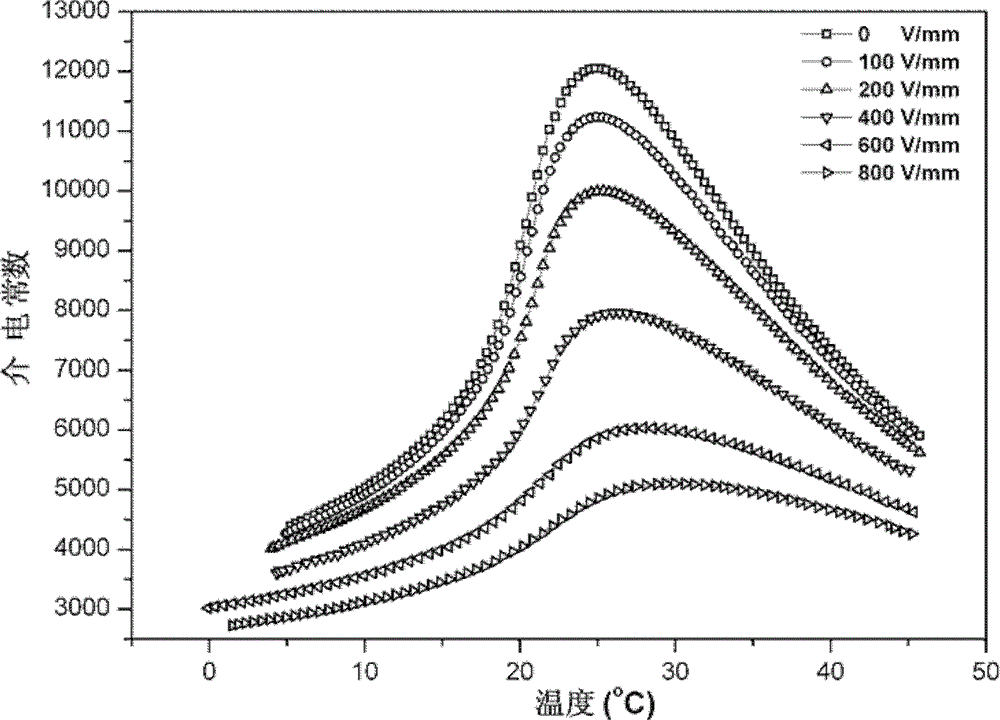

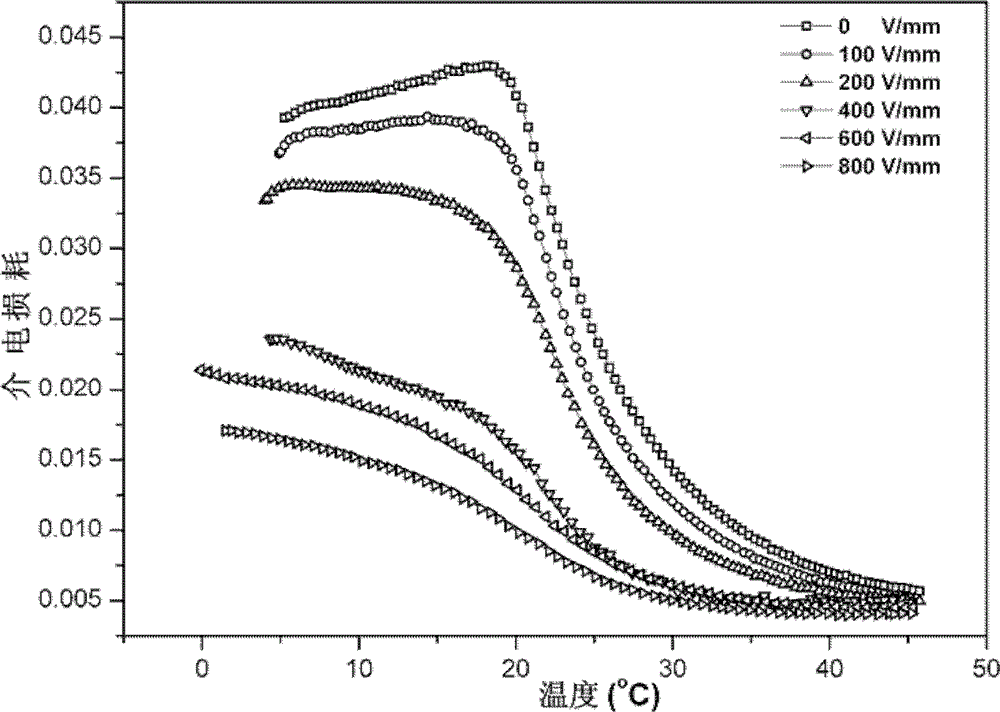

A technology of pyroelectric ceramics and barium strontium titanate, which is applied in the field of barium strontium titanate calcium pyroelectric ceramic materials and its preparation, can solve the problems of large grain size and achieve small grain size and dielectric strength. The effect of large constant and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] According to the general formula Ba 0.5928 (Sr 0.3 Ca 0.1 ) 0.993 Y 0.007 Ti 0.999 mn 0.001 o 3 Measure the stoichiometric ratio of Ti(OCH(CH 3 ) 2 ) 4 , Ba(CH 3 COO) 2 , Sr(CH 3 COO) 2 0.5H 2 O, Ca(NO 3 ) 2 , Y(NO 3 ) 3 and Mn(NO 3 ) 2 , the Ti(OCH(CH 3 ) 2 ) 4 Dissolve in the mixed solution of lactic acid and water, adjust the pH value of the solution between 8; then Ba(CH 3 COO) 2 , Sr(CH 3 COO) 2 0.5H 2 O, Ca(NO 3 ) 2 , Y(NO 3 ) 3 and Mn(NO 3 ) 2 Dissolve in water; then mix the above two solutions, stir and add water to form a mixed solution with a mass concentration of 15%, and then adjust the pH value of the solution to 6 to obtain a barium strontium calcium titanate precursor solution.

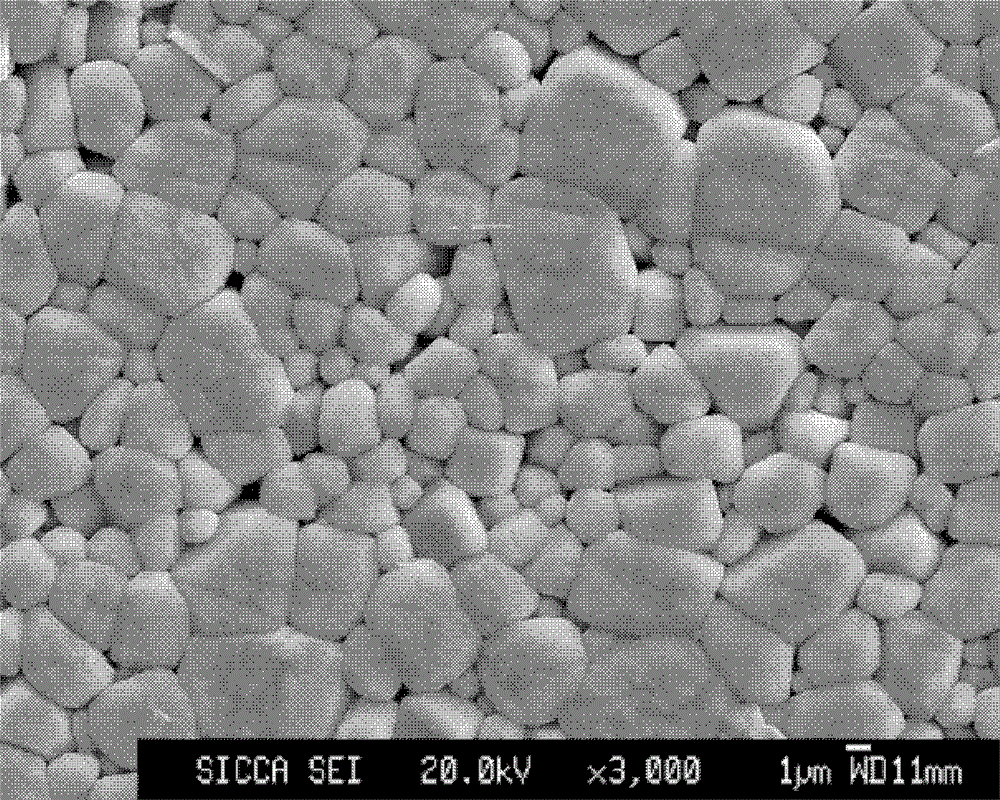

[0029] The barium strontium calcium titanate precursor solution was directly calcined at 800° C. for 2 hours to obtain barium strontium calcium titanate powder. The barium strontium calcium titanate powder is ground and pulverized through a 40-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com