Treatment solution and treatment method for preparing golden cryolite conversion film on surface of aluminum alloy

A technology of aluminum alloy surface and treatment method, applied in the direction of metal material coating process, etc., can solve the problems of film forming speed and treatment cost gap, unfavorable online judgment, promotion and application limitations, etc., to achieve good bonding force, which is conducive to online judgment. , The effect of film surface densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

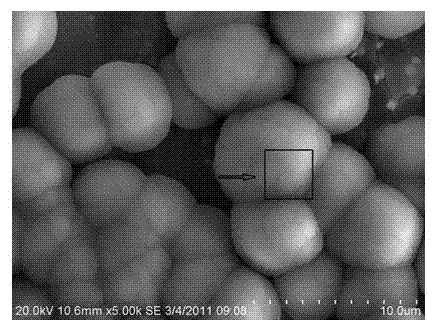

Image

Examples

Embodiment 1

[0075] Example 1: Preparation of golden yellow organic-inorganic composite conversion film on the surface of 6063 aluminum alloy

[0076] The process for preparing a golden-yellow cryolite organic-inorganic composite chemical conversion film on the surface of an aluminum alloy includes the following steps:

[0077] (1) Pretreatment: ① Take 6 samples of 30×30mm from 6063 large-size aluminum alloy profiles (thickness 3mm), grind the samples step by step with 600# and 800# water sandpaper, and clean them with deionized water; ② Put the aluminum alloy treated by ① into the mixed acid solution (H 2 SO 4 10% wt, H 3 PO 4 10%wt, HF 2 %wt) for 2 minutes, rinse with deionized water; ③ put the aluminum alloy treated in ② into the mixed alkali solution (NaOH 10%wt, NaOH 2 CO 3 15%wt) for 1 minute, rinse with deionized water.

[0078] (2) Preparation of treatment solution for preparing golden cryolite organic-inorganic composite conversion coating on the surface of aluminum allo...

Embodiment 2

[0081] Example 2 : Preparation of golden yellow organic-inorganic composite conversion coating on the surface of 6063 aluminum alloy

[0082] The process for preparing a golden-yellow cryolite organic-inorganic composite chemical conversion film on the surface of an aluminum alloy includes the following steps:

[0083] (1) Pretreatment: ① Take 6 samples of 30×30mm from 6063 large-size aluminum alloy profiles (thickness 3mm), grind the samples step by step with 600# and 800# water sandpaper, and clean them with deionized water; ② Put the aluminum alloy treated by ① into the mixed acid solution (H 2 SO 4 30%wt, H 3 PO 4 5%wt, HF 1%wt) for 1 minute, rinse with deionized water; ③ put the aluminum alloy treated in ② into a mixed alkali solution (NaOH 5%wt , NaOH 2 CO 3 20%wt) for 2 minutes, rinse with deionized water.

[0084] (2) Preparation of treatment solution for preparing golden cryolite organic-inorganic composite conversion coating on aluminum alloy surface: 5.0...

Embodiment 3

[0087] Example 3 : Preparation of golden yellow organic-inorganic composite conversion coating on the surface of 6063 aluminum alloy

[0088] The process for preparing a golden-yellow cryolite organic-inorganic composite chemical conversion film on the surface of an aluminum alloy includes the following steps:

[0089] (1) Pretreatment: ① Take 6 samples of 30×30mm from 6063 large-size aluminum alloy profiles (thickness 3mm), grind the samples step by step with 600# and 800# water sandpaper, and clean them with deionized water; ② Put the aluminum alloy treated by ① into the mixed acid solution (H 2 SO 4 20%wt, H 3 PO 4 20%wt, HF 5%wt) for 2 minutes, rinse with deionized water; ③ put the aluminum alloy treated in ② into the mixed alkali solution (NaOH 10%wt, NaOH 2 CO 3 15%wt) for 3 minutes, rinse with deionized water.

[0090] (2) Preparation of treatment solution for preparing golden cryolite organic-inorganic composite conversion coating on the surface of aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current density | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com