Alprostadil lipid nanosphere freeze-drying injection and preparation method thereof

A technology of freeze-dried injection and dil lipid, applied in the field of medicine, can solve the problems of main drug stability and transportation, storage influence, particle size effect of difficult emulsion, thermodynamic instability, etc., and achieves reduction of pulmonary circulation inactivation and physical stability. The effect of stable sex and good transportation convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

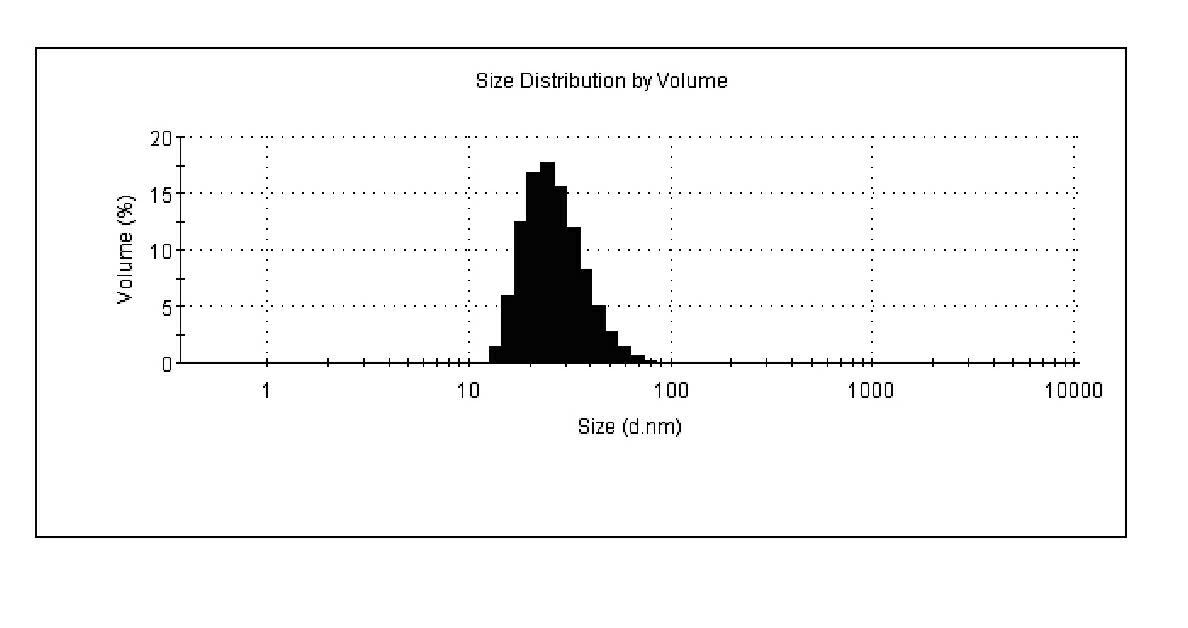

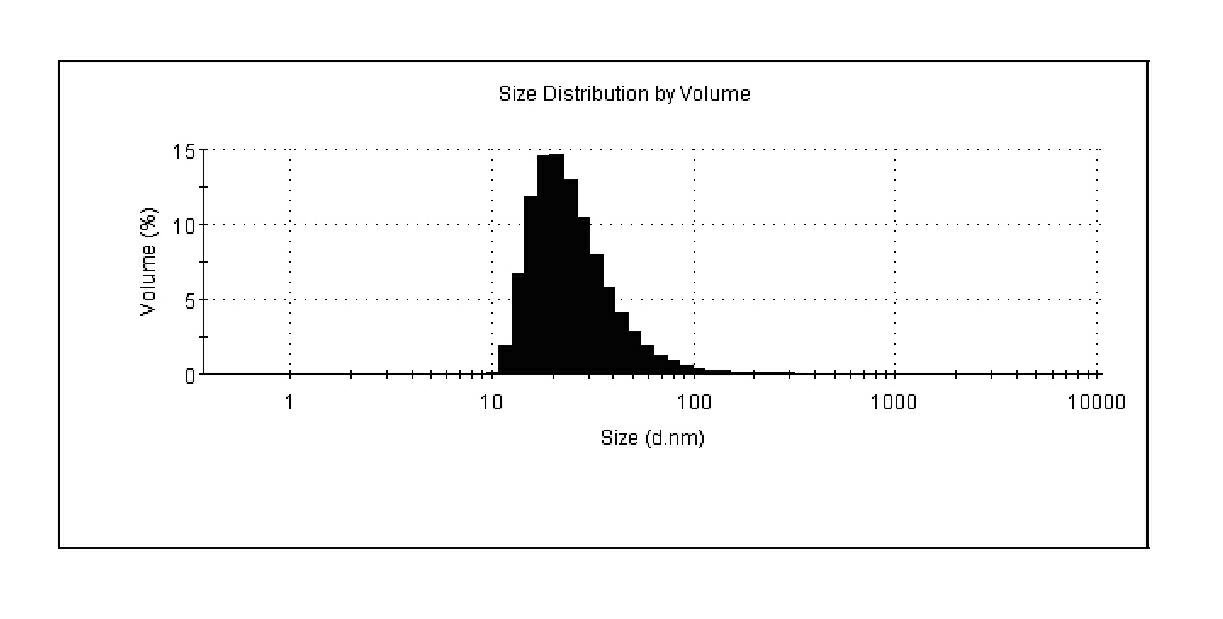

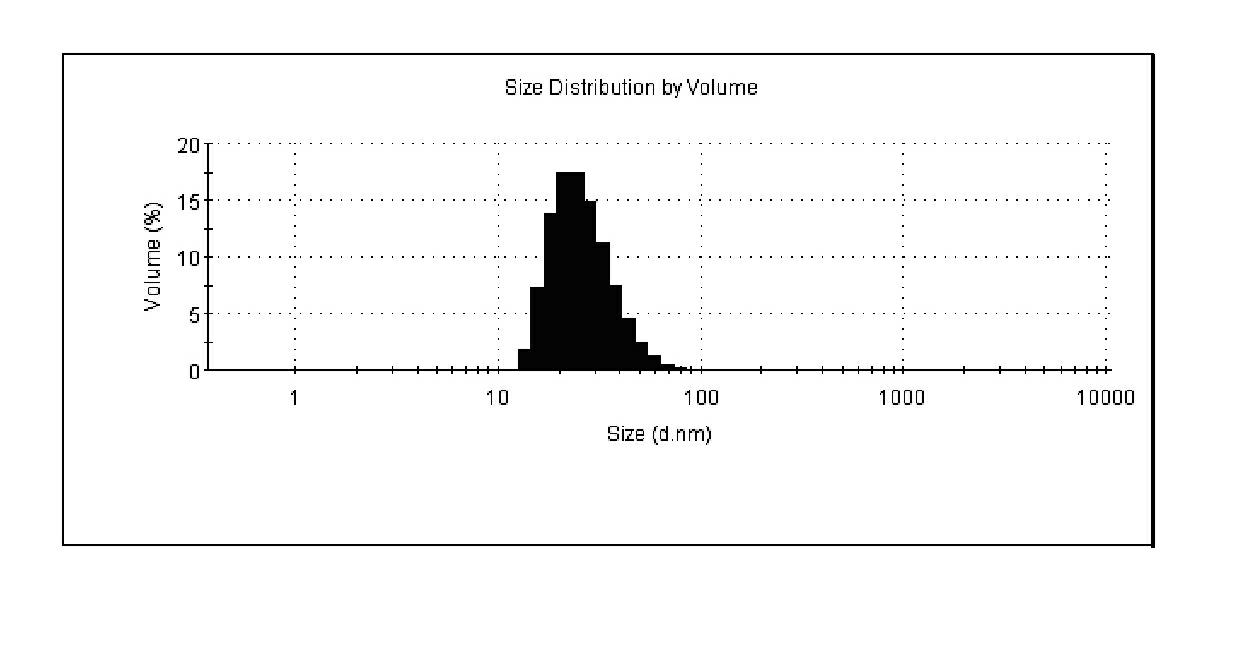

Image

Examples

Embodiment 1

[0043] The lyophilized injection of alprostadil lipid nanospheres of the present invention is made of the following components in parts by weight:

[0044] Alprostadil 0.0005g

[0045] Medium Chain Oil (MCT) 15g

[0046] Soy lecithin (S-75) 3g

[0047] Macrogol Lauryl Hydroxystearate 12g

[0048] Glycerin 22g

[0049] Trehalose 100g

[0050] Hydroxypropyl-β-cyclodextrin 20g

[0051] The preparation method of described alprostadil lipid nanosphere lyophilized injection preparation comprises the following steps: in aseptic workshop or 100-grade purification workshop, take medium-chain oil, soybean lecithin and polysaccharide by the weight that above-mentioned embodiment provides Mix ethylene glycol lauryl hydroxystearate, heat to 65±5°C, add alprostadil according to the stated weight to make it dissolve, slowly add 65±5°C according to the stated weight of glycerin and The mixed solution of 430g water, and be settled to 500ml with water for injection, stir and be cooled to ...

Embodiment 2

[0061] The alprostadil lipid nanosphere freeze-dried injection of the present invention is made of the following components in parts by weight:

[0062] Alprostadil 0.0005g

[0063] Medium Chain Oil (MCT) 15g

[0064] Soy lecithin (S-75) 6.4g

[0065] Polyethylene glycol lauryl hydroxystearate 8.5g

[0066] Glycerin 22g

[0067] Trehalose 20g

[0068] Hydroxypropyl-β-cyclodextrin 100g

[0069] The preparation method of alprostadil lipid nanosphere lyophilized injection preparation of the present invention comprises the following steps: in aseptic workshop or 100-grade purification workshop, take medium-chain oil, soybean lecithin (S -75) mixed with polyethylene glycol lauryl hydroxystearate, heated to 65±5°C, added alprostadil according to the stated weight to make it dissolve, and slowly added at 65±5°C under stirring The mixed solution of the glycerin of stated weight and 430g water, and be settled to 500ml with water for injection, stir and be cooled to room temperatu...

Embodiment 3

[0071] The alprostadil lipid nanosphere freeze-dried injection of the present invention is made of the following components in parts by weight:

[0072] Alprostadil 0.1g

[0073] Medium Chain Oil (MCT) 60g

[0074] Soy lecithin (S-75) 12g

[0075] Macrogol Lauryl Hydroxystearate 48g

[0076]Glycerin 22g

[0077] Trehalose 200g

[0078] Hydroxypropyl-β-cyclodextrin 300g

[0079] The preparation method of alprostadil lipid nanosphere lyophilized injection preparation of the present invention comprises the following steps: in aseptic workshop or 100-grade purification workshop, take medium-chain oil, soybean lecithin (S -75) mixed with polyethylene glycol lauryl hydroxystearate, heated to 65±5°C, added alprostadil according to the stated weight to make it dissolve, and slowly added at 65±5°C under stirring The mixed solution of the glycerin of stated weight ratio and 350g water, and be settled to 500ml with water for injection, stir and be cooled to room temperature, obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com