Film for raising abrasion resistance of compressor slide plate and preparation method thereof

A wear resistance, compressor technology, applied in the direction of mechanical equipment, chemical instruments and methods, components of pumping devices for elastic fluids, etc., can solve the increased friction of sliding vanes, surface treatment technology can not meet the needs, etc. problem, achieve the effect of improving bonding force, high hardness and high matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

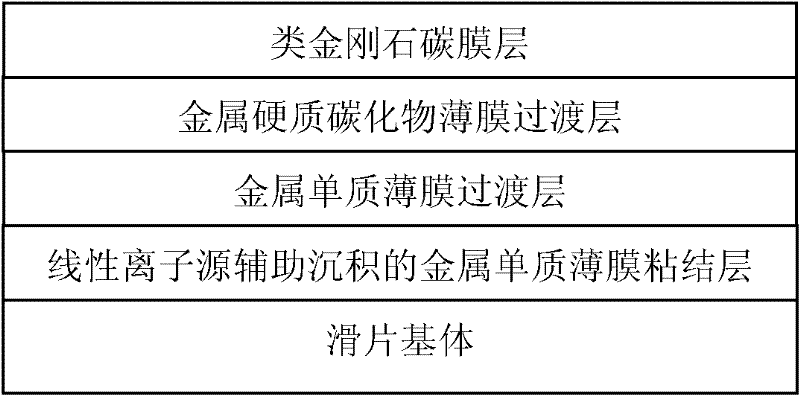

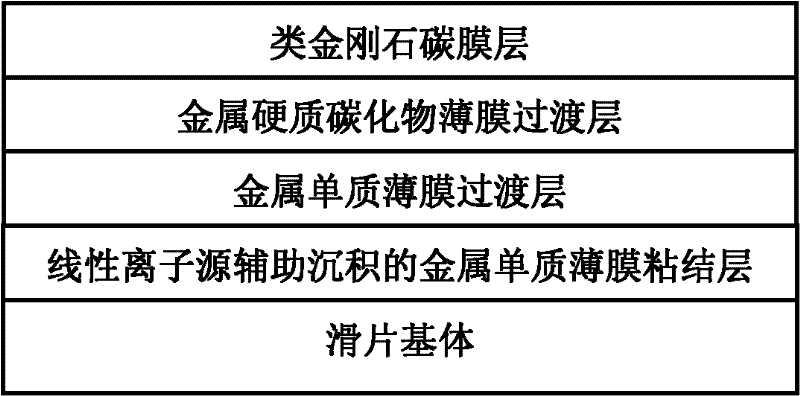

[0036] H13 hot work die steel is the substrate of the compressor sliding vane. The surface of the sliding vane substrate is a thin film composed of multi-layer film structure. Starting from the surface of the sliding vane substrate, the first layer is a simple chromium thin film bonding layer assisted by a linear ion source. The second layer is an elemental chromium film transition layer, the third layer is a hard carbide transition layer of chromium, and the fourth layer is a diamond-like carbon film layer.

[0037] The preparation method of the film on the surface of the above-mentioned slide substrate is as follows:

[0038] The coating equipment adopts a composite coating machine of magnetron sputtering and ion beam sputtering. The equipment includes a vacuum chamber, a magnetron sputtering source, a linear ion source and a workpiece bracket capable of revolving and rotating at the same time. The workpiece bracket is installed inside the vacuum chamber. A high-purity eleme...

Embodiment 2

[0048] 9Cr18 stainless steel is the substrate of the compressor slide vane. The surface of the slide vane base is a thin film composed of multi-layer film structure. Starting from the surface of the slide vane base, the first layer is an elemental titanium thin film bonding layer assisted by a linear ion source, and the second layer is It is an elemental titanium film transition layer, the third layer is a titanium hard carbide transition layer, and the fourth layer is a diamond-like carbon film layer.

[0049] The preparation method of the film on the surface of the above-mentioned slide substrate is as follows:

[0050] The coating equipment adopts a composite coating machine of magnetron sputtering and ion beam sputtering. The equipment includes a vacuum chamber, a magnetron sputtering source, a linear ion source and a workpiece bracket capable of revolving and rotating at the same time. The workpiece bracket is installed inside the vacuum chamber. A high-purity elemental t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com