Borosiliphosphate glass with high ultraviolet light transmissivity and preparation method thereof

A borosilicate phosphate and ultraviolet light technology, which is applied to borosilicate phosphate glass and its preparation, borosilicate phosphate glass material with high ultraviolet light transmittance and its preparation field, can solve the problems of glass corrosion, easy deliquescence of glass, etc. Poor chemical stability and other problems, to achieve the effect of low production cost, low raw material purity requirements, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

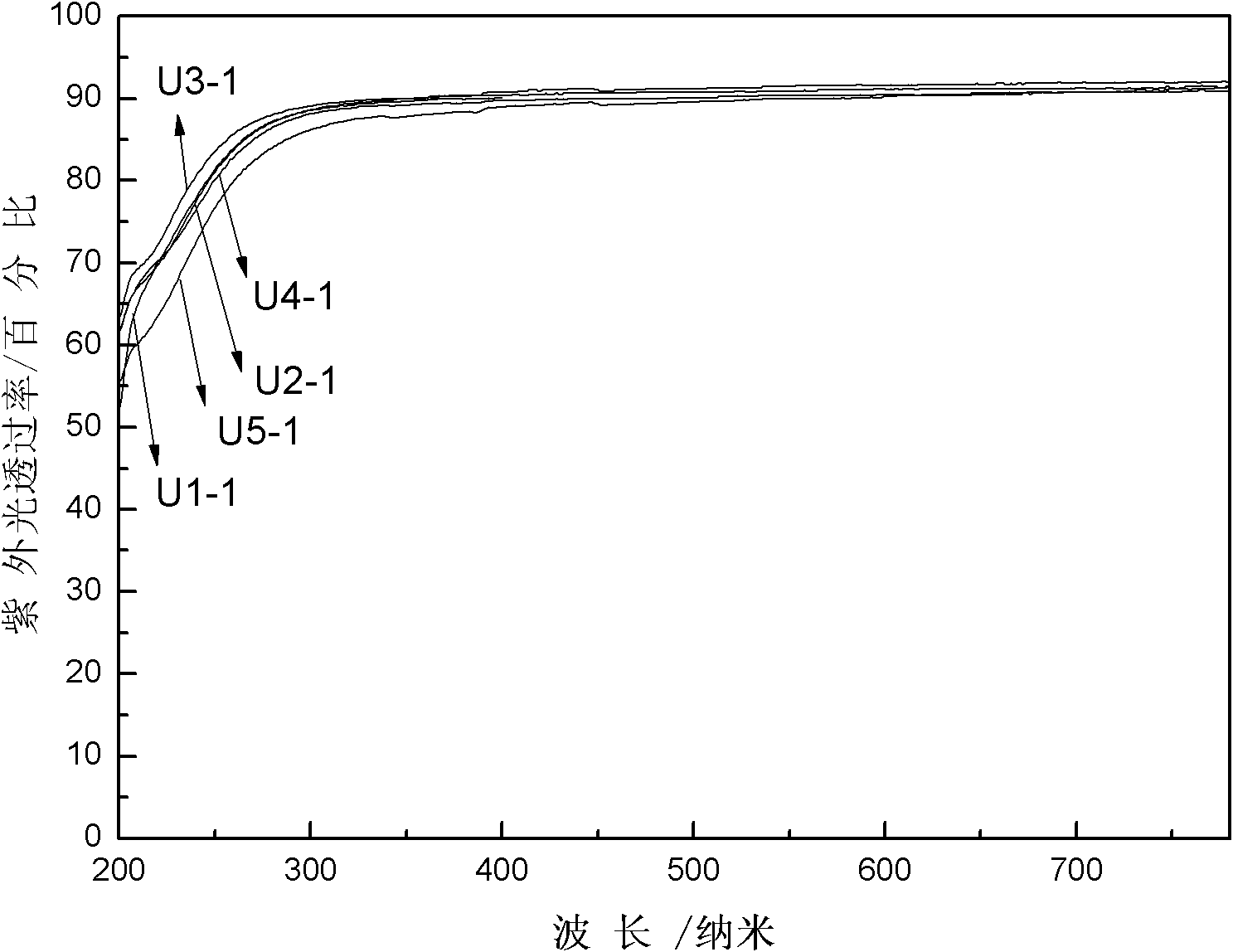

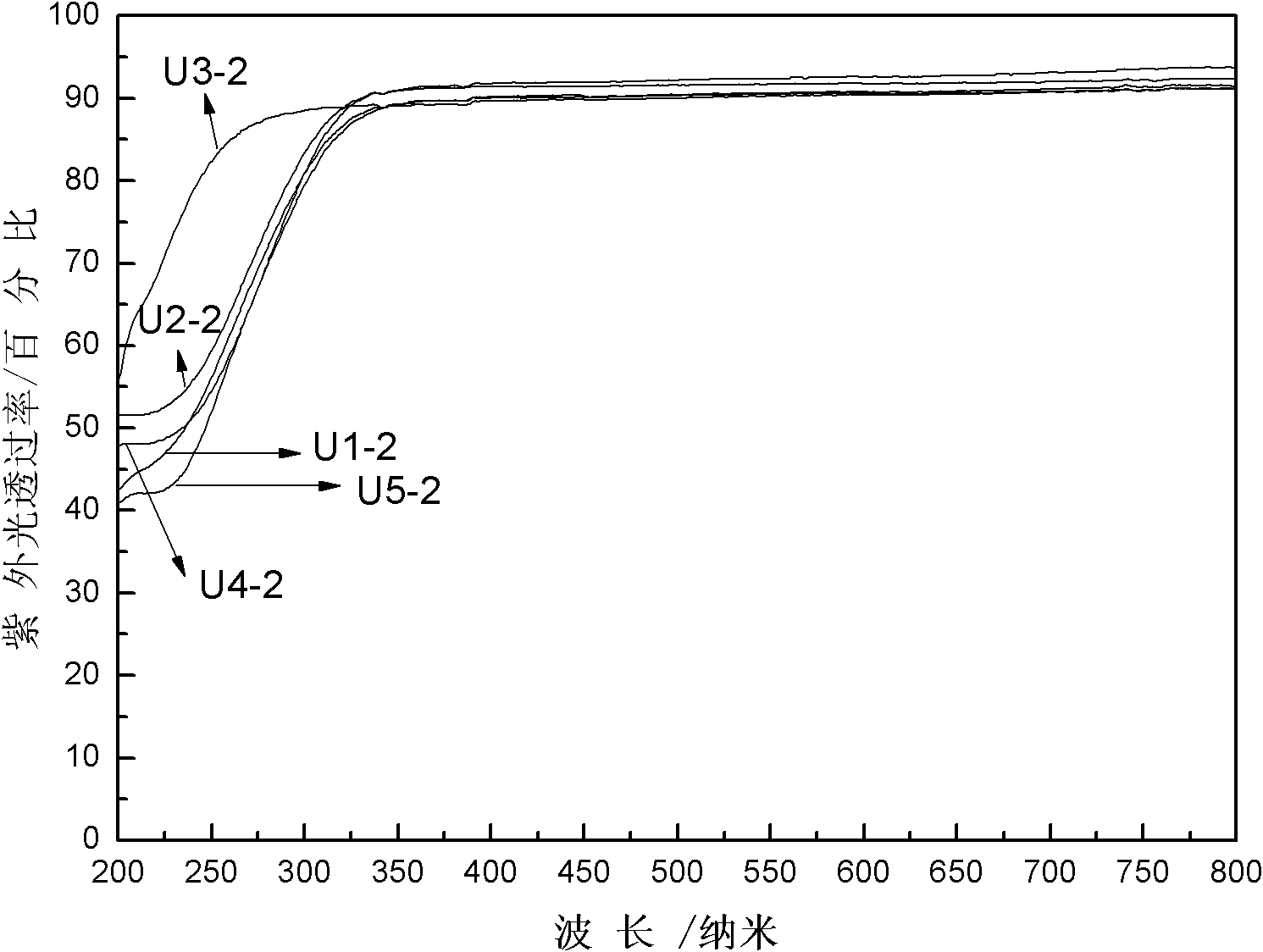

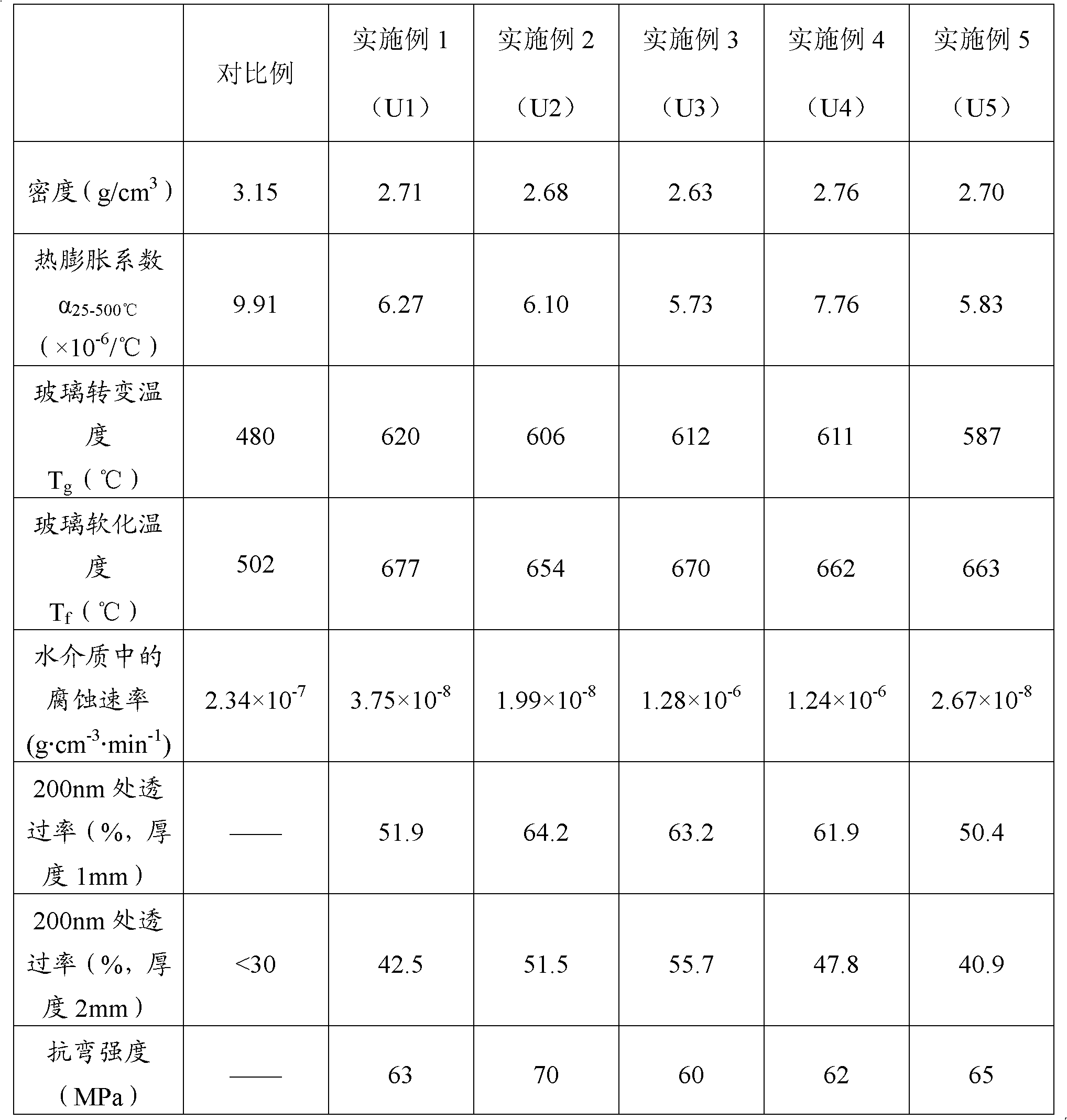

[0044] Embodiment 1 (numbering U1): the ultraviolet light-transmitting glass that the present invention relates to, its base glass is made of B 2 o 3 , SiO 2 ,P 2 o 5 , SrO, ZnO composition, the content of each composition is B 2 o 3 : 13.3mol%, SiO 2 : 33.3mol%, P 2 o 5 : 33.3 mol%, SrO: 10.0 mol%, ZnO: 10.0 mol%.

Embodiment 2

[0045] Embodiment 2 (numbering U2): the ultraviolet light-transmitting glass that the present invention relates to, its base glass is made of B 2 o 3 , SiO 2 ,P 2 o 5 , SrO, ZnO composition, the content of each composition is B 2 o 3 : 16.7mol%, SiO 2 : 30.0mol%, P 2 o 5 : 33.3 mol%, SrO: 10.0 mol%, ZnO: 10.0 mol%.

Embodiment 3

[0046] Embodiment 3 (numbering U3): the ultraviolet light-transmitting glass that the present invention relates to, its base glass is made of B 2 o 3 , SiO 2 ,P 2 o 5 , SrO composition, the content of each composition is B 2 o 3 : 16.7mol%, SiO 2 : 30.0mol%, P 2 o 5 : 33.3 mol%, SrO: 20.0 mol%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com