Method and equipment for manufacturing optical fiber perform rod casing pipe with complicated refractive index profile

A technology of refractive index profile and optical fiber preform, which is applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of single refractive index of optical fiber preform sleeve, and achieve the requirements of low raw material purity, high deposition rate, and improved manufacturing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

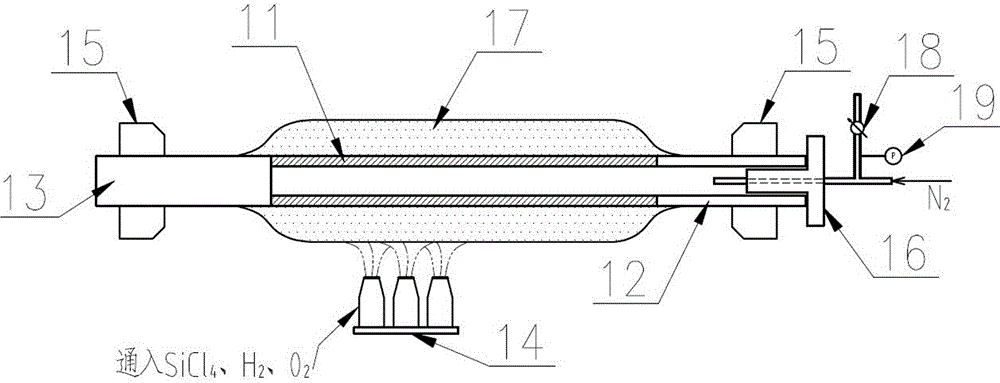

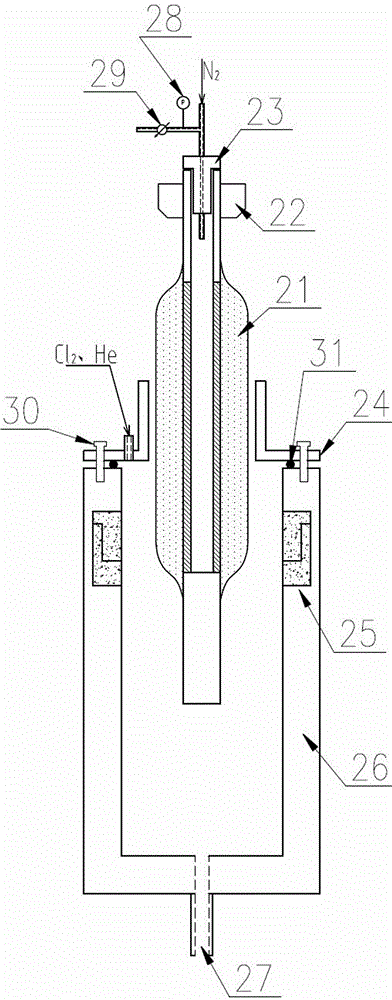

[0037] Refer to attached figure 1 , 2 , a manufacturing equipment for an optical fiber preform sleeve with a complex refractive index profile is composed of a powder sleeve manufacturing device and a powder sleeve vitrification device.

[0038] The powder casing manufacturing device includes a rotary chuck-15, a blowtorch 14, a sealed rotary joint-16, a pressure regulating valve-18 and a pressure gauge-19. One end of the liner 11 is connected with the hollow tailpipe 12, the other end of the liner 11 is connected with the solid tailpipe 13, the solid tailpiece 13 is clamped by the rotary chuck 220, and the hollow tailpipe 12 is clamped by the rotary chuck 15 (target tube), the hollow end of the hollow tail tube 12 (target tube) is sealed with a sealed rotary joint 16, and pressure is applied to the tube through the sealed rotary joint 16; the pressure regulating valve 18 is connected with the sealed rotary joint 16 to adjust the Pressure; pressure gauge one 19 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com