Preparation method and application of catalyst for one-step preparation of p-aminophenol from nitrobenzene

A technology of p-aminophenol and nitrobenzene, which is applied in the field of preparation of catalysts for the preparation of p-aminophenol by one-step method of nitrobenzene, can solve the problems of relatively large impact on catalyst life, reduced catalyst service life, poor PAP selectivity, etc., and achieves strong Anti-sulfur poisoning performance, reduced catalytic cost, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

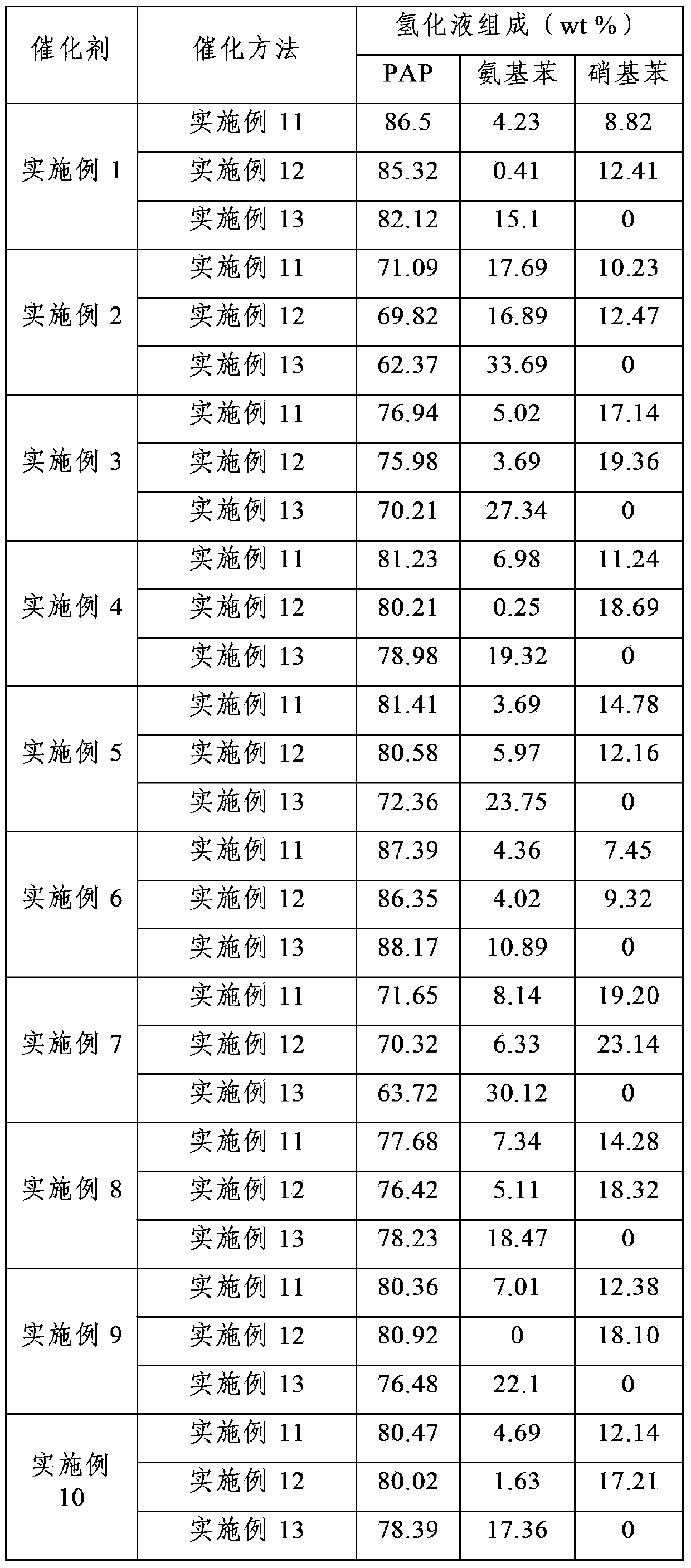

Examples

Embodiment 1

[0027] Step 1, pretreatment of activated carbon: add 20g of powdered activated carbon to 150mL of nitric acid solution with a mass concentration of 4%, boil for 2 hours, filter after cooling; then wash the filtered solid with deionized water until the pH value is 7; The washed solid was added to 150 mL of 8% hydrochloric acid solution and boiled for 0.8 h, filtered after cooling, and the filtered solid was washed with deionized water until neutral to obtain pretreated activated carbon;

[0028] Step 2. Platinum salt loading: Add 19.56 g of the pretreated activated carbon described in step 1 into 390 mL of deionized water, and heat to 80° C. under stirring conditions to disperse the pretreated activated carbon in the deionized water evenly to obtain a carbon slurry; Then, under stirring conditions, slowly dropwise add a platinum chloride aqueous solution having a platinum content of 0.4 g and a concentration of 0.01 g / mL to the carbon slurry, and then keep stirring for 1 h after...

Embodiment 2

[0032]Step 1, pretreatment of activated carbon: add 20g of powdered activated carbon to 200mL of nitric acid solution with a mass concentration of 5%, boil for 1h, filter after cooling; then wash the filtered solid with deionized water until the pH value is 5; The washed solid was added to 200 mL of 5% hydrochloric acid solution and boiled for 1 h, filtered after cooling, and the filtered solid was washed with deionized water until neutral to obtain pretreated activated carbon;

[0033] Step 2. Platinum salt loading: Add 18.6 g of the pretreated activated carbon described in step 1 into 370 mL of deionized water, and heat to 90° C. under stirring conditions to disperse the pretreated activated carbon in the deionized water evenly to obtain a carbon slurry; Then, slowly dropwise adding platinum nitrate aqueous solution of 0.02 g / mL with a platinum content of 1 g to the carbon slurry under stirring conditions, after the dropwise addition, it was incubated and stirred for 2 hours ...

Embodiment 3

[0037] Step 1. Pretreatment of activated carbon: add 20 g of powdered activated carbon to 100 mL of 3% nitric acid solution and boil for 3 hours, filter after cooling; then wash the filtered solid with deionized water until the pH value is 6; The washed solid was added to 100 mL of 10% hydrochloric acid solution and boiled for 0.5 h, filtered after cooling, and the filtered solid was washed with deionized water until neutral to obtain pretreated activated carbon;

[0038] Step 2. Platinum salt loading: Add 19.2 g of the pretreated activated carbon described in step 1 into 100 mL of deionized water, and heat to 85° C. under stirring conditions to disperse the pretreated activated carbon in the deionized water evenly to obtain a carbon slurry; Then, under stirring conditions, slowly dropwise add a platinum acetate solution with a platinum content of 0.6 g and a concentration of 0.001 g / mL in the carbon slurry, and then insulate and stir for 0.5 h after the dropwise addition, to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com