Hard alloy taking nickel-aluminium intermetallic compound Ni3Al as binding phase and preparation method

A technology of intermetallic compounds and hard alloys, which is applied in the field of hard alloys toughened and reinforced by rare earth elements, can solve the problems of additive preparation methods, complicated processes, and poor stability of Co-Y, and achieve improved high-temperature oxidation resistance and easy The effect of low decomposition and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

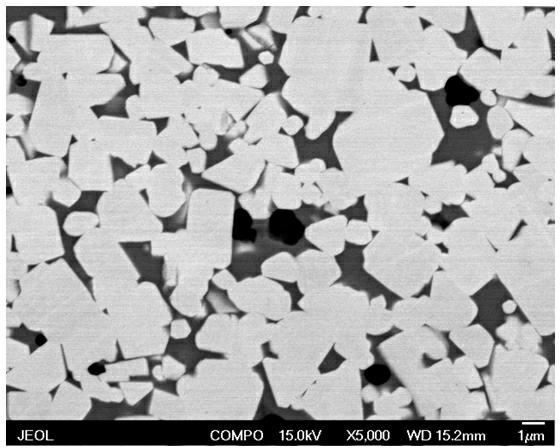

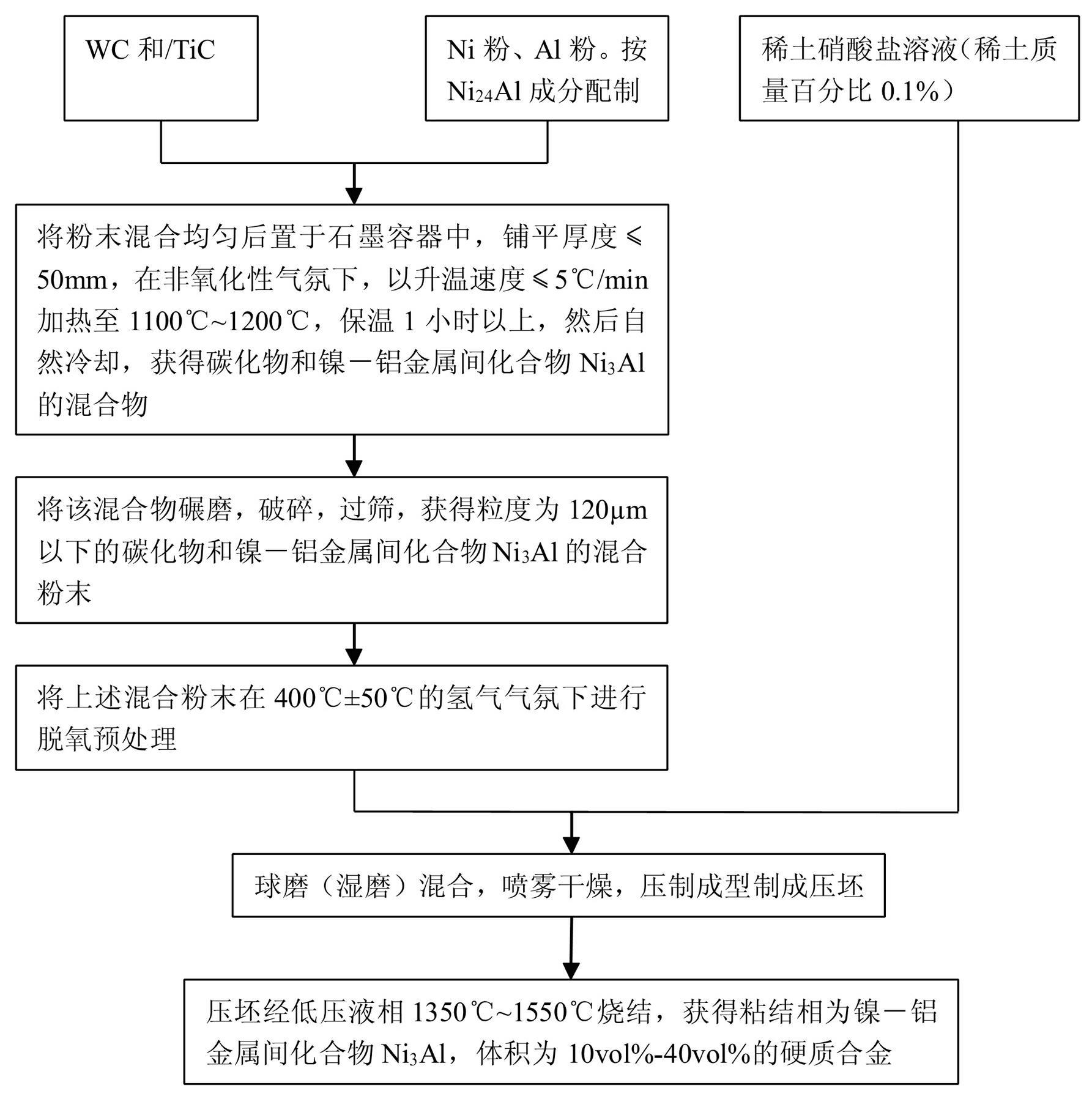

[0025] Embodiment 1: According to figure 1 The flow shown, press Ni 24 The composition ratio of Al, the mass percentage is 5.04% nickel powder and aluminum powder, mixes evenly with the rest of the tungsten carbide powder; Place the above-mentioned mixed powder in a graphite container to pave the thickness of 50mm, under the non-oxidizing atmosphere, with 5 The heating rate of ℃ / min is heated to 1100℃, kept for 7 hours, and then cooled naturally to obtain tungsten carbide and nickel-aluminum intermetallic compound Ni 3 A mixture of Al; the mixture is ground, crushed, and passed through a 250-mesh sieve to obtain tungsten carbide and nickel-aluminum intermetallic compound Ni with a particle size of 58 μm or less. 3 Mixed powder of Al; the above-mentioned tungsten carbide and nickel-aluminum intermetallic compound Ni 3 The mixed powder of Al is subjected to deoxidation pretreatment under a hydrogen atmosphere at 400°C±50°C; then, according to the amount of Y in the final ceme...

Embodiment 2

[0026] Embodiment 2: According to figure 1 The flow shown, press Ni 24 The composition ratio of Al, the mass percentage is 10.67% nickel powder and aluminum powder, mixes evenly with the remainder tungsten carbide powder; Place the above-mentioned mixed powder in a graphite container to pave a thickness of 30mm, under a non-oxidizing atmosphere, with 3 The heating rate of ℃ / min is heated to 1130℃, kept for 5 hours, and then cooled naturally to obtain tungsten carbide and nickel-aluminum intermetallic compound Ni 3 A mixture of Al; the mixture is ground, crushed, and passed through a 200-mesh sieve to obtain tungsten carbide and nickel-aluminum intermetallic compound Ni with a particle size of less than 75 μm 3 Mixed powder of Al; the above-mentioned tungsten carbide and nickel-aluminum intermetallic compound Ni 3 The mixed powder of Al is subjected to deoxidation pretreatment under a hydrogen atmosphere at 400°C±50°C; then, according to the amount of Y in the final cemented...

Embodiment 3

[0027] Embodiment 3: According to figure 1 The flow shown, press Ni 24 The composition ratio of Al, the mass percentage is 16.99% nickel powder and aluminum powder, mix with the balance tungsten carbide powder evenly; Place the above-mentioned mixed powder in a graphite container and spread it to a thickness of 20mm. Under a non-oxidizing atmosphere, use 1 Heating rate of ℃ / min to 1160 ℃, holding temperature for 3 hours, then cooling naturally to obtain tungsten carbide and nickel-aluminum intermetallic compound Ni 3 A mixture of Al; the mixture is ground, crushed, and passed through a 160-mesh sieve to obtain tungsten carbide and nickel-aluminum intermetallic compound Ni with a particle size of 96 μm or less. 3 Mixed powder of Al; the above-mentioned tungsten carbide and nickel-aluminum intermetallic compound Ni 3 The mixed powder of Al is subjected to deoxidation pretreatment under a hydrogen atmosphere at 400°C±50°C; then, according to the amount of Y in the final cement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com