Method for preparing rodlike cobaltosic oxide nano structure

A cobalt tetroxide rod and nanostructure technology, which is applied in chemical instruments and methods, cobalt oxide/cobalt hydroxide, nanotechnology and other directions, can solve the problems of water pollution by chemical methods, cumbersome preparation process, etc., and achieves simple equipment, great application prospects, The effect of improving the performance of lithium-ion batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The experimental methods described in the following examples are conventional methods unless otherwise specified; the reagents and materials can be obtained from commercial sources unless otherwise specified.

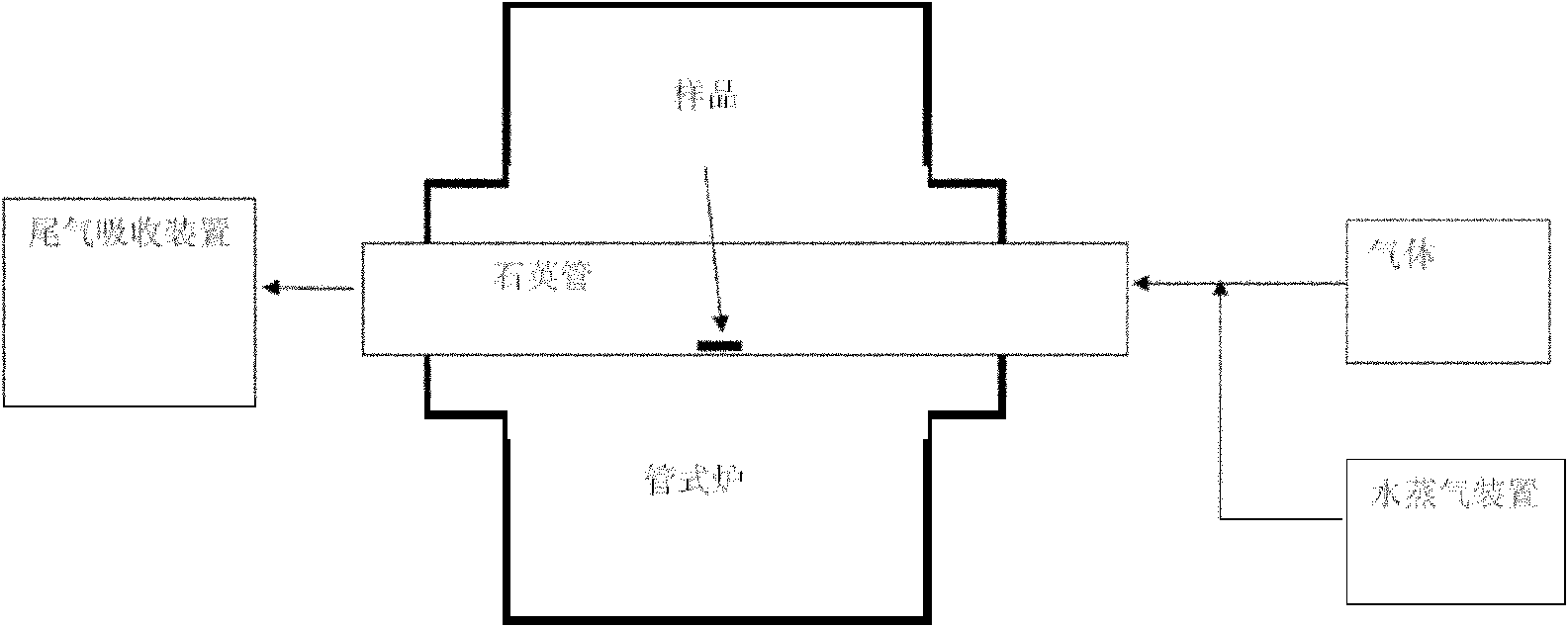

[0017] The invention adopts the direct oxidation method to realize the preparation of high-density cobalt tetroxide nano-rod-like structure in a pure argon atmosphere containing water vapor. See the schematic diagram of the device figure 1 , and its preparation process is as follows:

[0018] (a) Before all experiments, the device for heating water was turned on. When heating the sample, the water temperature is at the set temperature.

[0019] (b) The industrial cobalt sheet with a purity of 99.8% is divided into small pieces of about 1 cm×1 cm, and then the sample is pressed flat by a tablet press under the pressure of 10 Mpa.

[0020] (c) Sand the sample sequentially with 300, 400, 500, 800, 1000 and 2000# sandpaper to remove the surface oxide layer and mak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com