Method for preparing high-density zinc oxide nano granules

A zinc oxide nanometer, high-density technology, applied in chemical instruments and methods, zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problems of no public reports, etc., to achieve precise size control, uniform particle shape and distribution, The effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

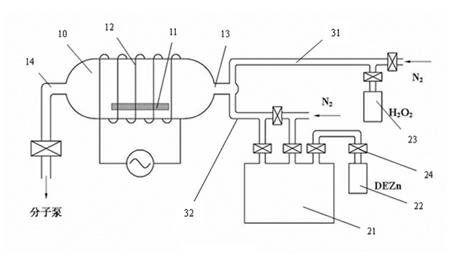

[0034] When working, the saturated vapor of diethyl zinc and nitrogen (N 2) are mixed and diluted in the dilution bottle 21, and the diluted mixed gas and the saturated vapor of hydrogen peroxide enter the reaction chamber 10 alternately in the form of gas pulses. The air pressure in the reaction chamber 10 is maintained at about 220 Pa before the gas pulse comes, and the heating coil 12 keeps the temperature of the reaction chamber 10 and the substrate 11 at 300°C. The substrate 11 for depositing ZnO nanoparticles is a silicon wafer cleaned by standard RCA, and the flow rate of nitrogen gas used to dilute diethyl zinc is 400 sccm.

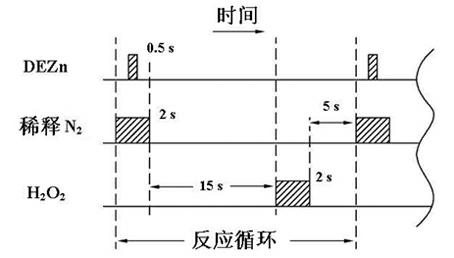

[0035] In an atomic layer deposition cycle, the pulse and cleaning time of diethyl zinc and hydrogen peroxide are as follows figure 2 Shown: Step 1, feed nitrogen into the reaction chamber, and then feed saturated vapor of diethyl zinc during the duration of the nitrogen pulse. The pulse time of diethyl zinc is 0.5 s, which is used to dilute the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com