Preparation method for nanoscale transition metal nitride/carbon composite material

A carbon composite material and transition metal technology, applied in the field of material science, can solve problems such as product inhomogeneity, and achieve the effect of improving specific capacity and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

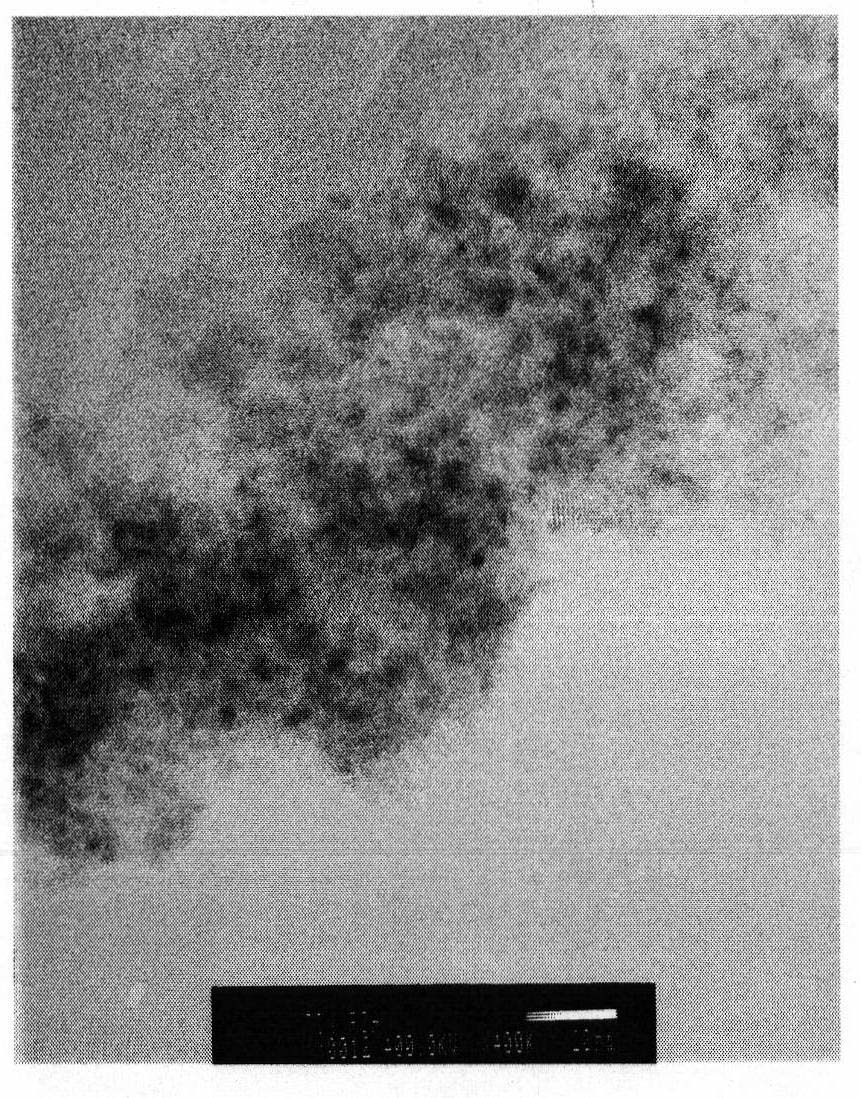

Image

Examples

Embodiment 1

[0024] Add 27mL of 37% (w / w) formaldehyde solution into a 150mL three-neck flask with a stirring and temperature-controlled water bath device, adjust the pH value to 7.5-8.5 with 10% sodium hydroxide solution, add 5g of urea, and heat up in the water bath After reacting at 90°C for 2 hours, add 2.5g of P123, adjust the pH to 5.0-5.4 with 5% dilute hydrochloric acid, continue the reaction for 30 minutes, cool and adjust the pH to 7.0-7.6, and filter to obtain a mixture of urea-formaldehyde resin and P123. Under the protection of argon, the temperature of the mixture was raised to 200° C. at a rate of 5° C., heat-treated for 2 hours, and then continued to be heated at a rate of 1-10° C. to 350° C., and heat-treated for 5 hours to obtain mesoporous carbon nitride.

[0025] 228mg Ti(OC 2 h 5 ) 4 and 606mg VO(OC 2 h 5 ) 3 Dissolve in 2g of ethanol, add 0.5g of mesoporous carbon nitride to it, treat the mixture with ultrasonic vibration for 10min, then remove the air in the por...

Embodiment 2

[0027] Add 37% formaldehyde aqueous solution, 38mL to the four-neck flask equipped with stirrer, thermometer, condenser and dropping funnel, adjust pH=8-9 with 20% sodium hydroxide aqueous solution. Add 10g of melamine, stir and raise the temperature to 85°C. After the melamine is completely dissolved, keep warm until precipitation occurs. Continue the reaction for 1 hour. After adding 5g of P123, adjust the pH to 5.0-5.4 with 5% dilute hydrochloric acid, and continue the reaction for half an hour. After suction filtration, the mixture of melamine resin and P123 was obtained. Under the protection of argon, the mixture was heated to 200°C at a rate of 5°C, heat-treated for 2 hours, and then continued to heat up to 350°C at a rate of 1-10°C , heat treatment for 5 hours to obtain mesoporous carbon nitride.

[0028] 834mg of Ti(OC 2 h 5 ) 4 Dissolve in 2g of ethanol, add 0.5g of mesoporous carbon nitride to it, treat the mixture with ultrasonic vibration for 10min, then remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com