Groove notching and grid burying method for crystalline silicon solar cell

A technology of solar cells and crystalline silicon, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of high laser precision, slow speed, and inability to process in batches, and achieve the effect of low fragmentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

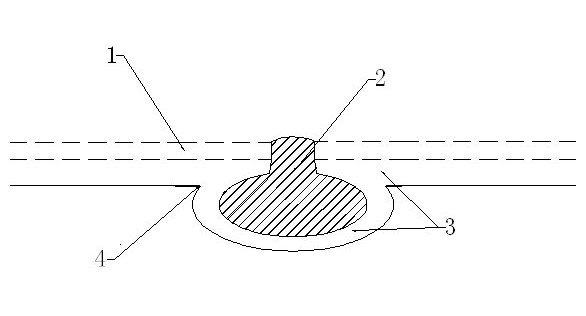

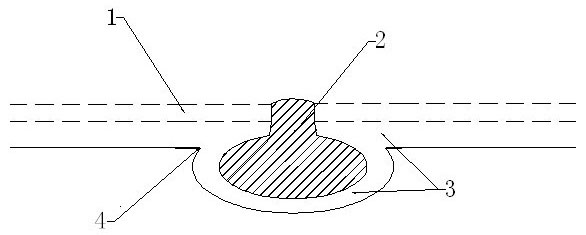

Embodiment 1

[0028] The polycrystalline silicon wafer 4 is selected; the silicon wafer 4 undergoes a conventional cleaning process, and the surface is textured. At 260°C, a silicon dioxide mask 1 of 80-100nm is deposited on the diffusion surface of the silicon wafer 4 by using the PECVD process, that is, the plasma-enhanced chemical vapor deposition method, and the reaction gas is SiH 4 and O 2 . Print the etching slurry on the electrode 2 on the diffusion surface of the silicon wafer 4 by screen printing. The etching slurry is an organic substance (Merck slurry) containing formic acid and ammonium hydroxide. After etching away the silicon dioxide mask 1 After the silicon wafer 4 is sprayed with pure water, ultrasonically cleaned, ultrasonically cleaned in dilute hydrochloric acid solution, rinsed with circulating pure water, and sprayed with pure water, it is placed in a container containing a 25% nitric acid solution for groove carving. Finally, the remaining impurities and acid soluti...

Embodiment 2

[0030] Example 2: Select a P-type monocrystalline silicon wafer; the silicon wafer undergoes a conventional cleaning process, and the surface is textured, and at a temperature of 400 ° C, 60% of the silicon wafer is deposited on the diffusion surface of the silicon wafer 4 by using the PECVD process, that is, the plasma-enhanced chemical vapor deposition method. ~80nm silicon nitride mask 1, the reaction gas is SiH 4 and NH 3 . Print the etching slurry on the electrode 2 on the diffusion surface of the silicon wafer 4 by screen printing. The etching slurry is an organic substance containing phosphoric acid, and the silicon wafer 4 after the silicon nitride mask 1 has been etched away is sprayed with pure water. , ultrasonic cleaning, ultrasonic cleaning in dilute hydrochloric acid solution, rinsing with circulating pure water, spraying with pure water, put it into a container containing a 15% sodium hydroxide solution for groove carving, and clean the silicon with deionized w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com