Cobaltous acetate-doped sol-gel film layer and preparation method thereof

A sol-gel, cobalt acetate technology, applied in coatings, metal material coating processes, solid-state chemical plating, etc., can solve the problems of reducing the stability of sol-gel, reducing corrosion resistance, and being unsuitable for long-term protection. Effects of strong social and economic value, improved corrosion resistance, good stability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

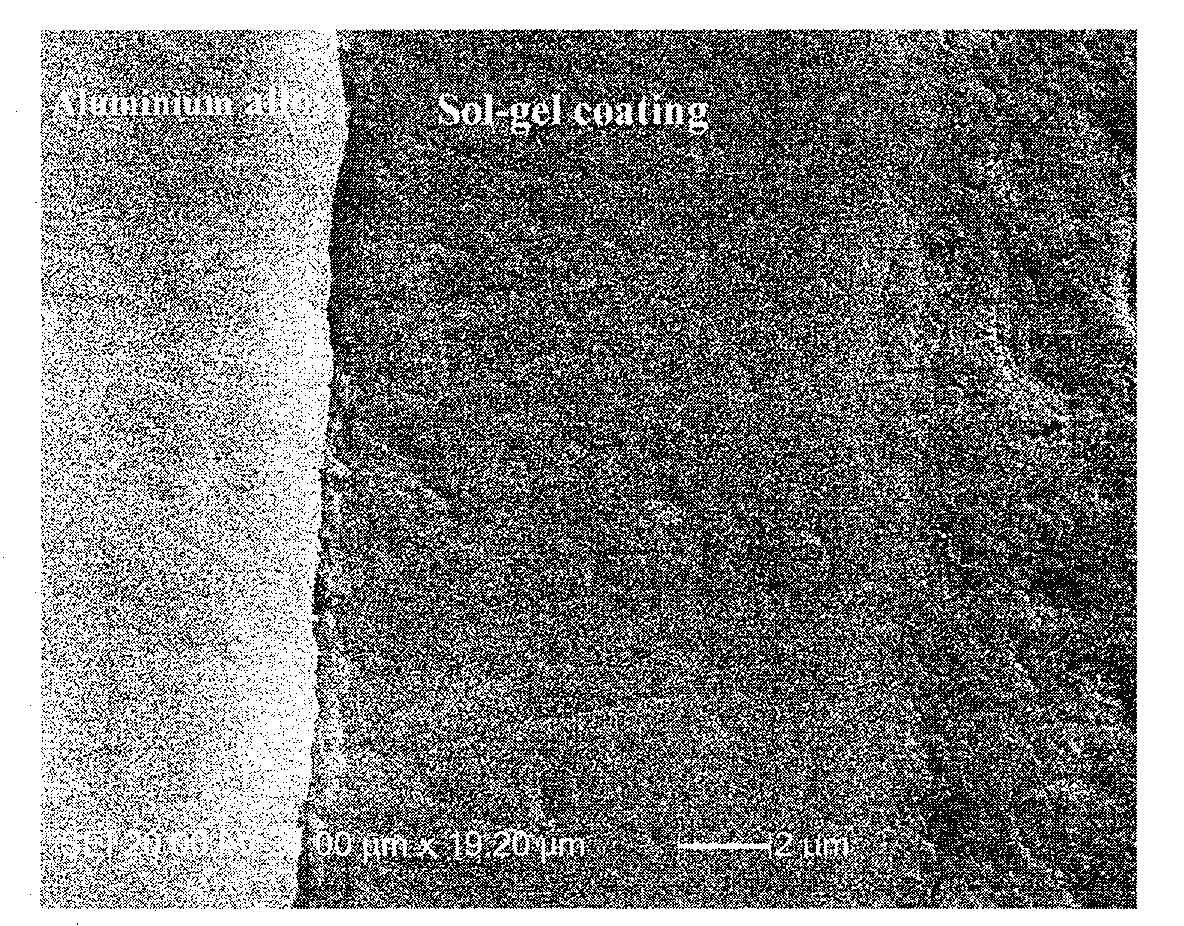

[0040] 1) Pretreatment of aluminum and aluminum alloys

[0041] ① Grinding: Grinding to 800# with sandpaper;

[0042] ②Washing with flowing tap water;

[0043] ③ Alkaline washing: Sodium hydroxide 55g / L, immerse at 50~60℃ for 30s;

[0044] ④Wash with hot water and then wash with running water;

[0045] ⑤ Idemitsu: chromic acid: 110g / L; nitric acid: 45g / L; hydrofluoric acid: 22g / L;

[0046] ⑥Wash with running water.

[0047] 2) Preparation of undoped sol

[0048] ① Use a graduated cylinder to measure 1L of absolute ethanol as a sol for later use;

[0049] ② Preparation of GTMS sol system: Slowly pour 60mL of GTMS into an appropriate amount of stirring solvent, then add excess deionized water to fully hydrolyze GTMS;

[0050]③Preparation of TPOZ sol system: using ethyl acetoacetate as catalyst, first fully stir 13mL of ethyl acetoacetate and an appropriate amount of solvent, then slowly add 26.7mL of TPOZ; after mixing evenly, slowly add deionized water dropwise, The mola...

Embodiment 2

[0059] 1) Pretreatment of aluminum and aluminum alloys

[0060] The specific process is the same as in Example 1.

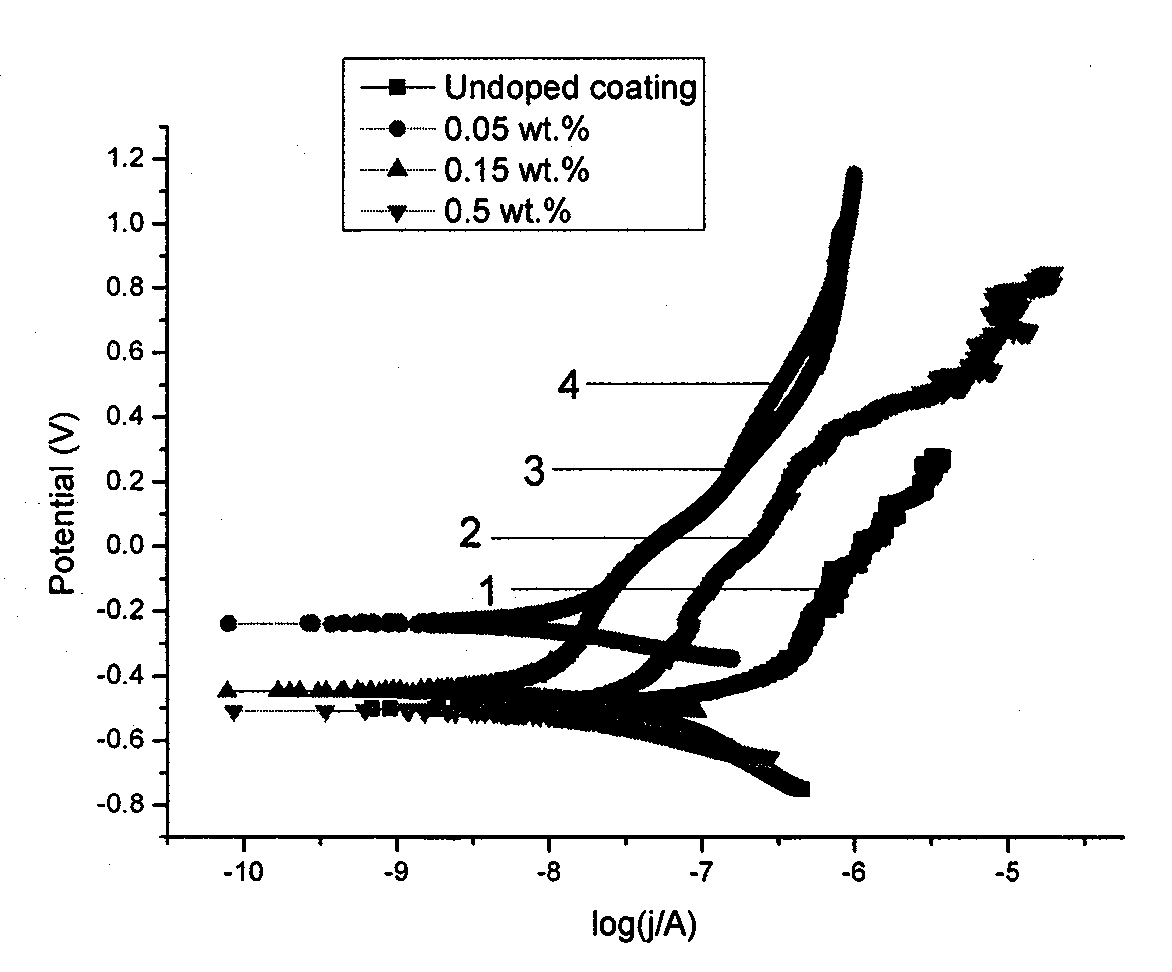

[0061] 2) Preparation of doped 0.05wt.% cobalt acetate sol

[0062] ① Use a graduated cylinder to measure 1L of absolute ethanol as a sol for later use;

[0063] ② Preparation of GTMS sol system: Slowly pour 60mL of GTMS into an appropriate amount of solvent under stirring, and then add excess deionized water to fully hydrolyze GTMS;

[0064] ③Preparation of TPOZ sol system: using ethyl acetoacetate as catalyst, first fully stir 13mL of ethyl acetoacetate and an appropriate amount of solvent, then slowly add 26.7mL of TPOZ; after mixing evenly, slowly add deionized water dropwise, The molar ratio of TPOZ to deionized water is 3:1;

[0065] ④The above two sol systems were respectively placed at room temperature and stirred for 0.5h;

[0066] Mix the above two sol systems and stir evenly;

[0067] ⑤ Weighing a certain amount of cobalt acetate, fully dissolving...

Embodiment 3

[0072] 1) Pretreatment of aluminum and aluminum alloys

[0073] The specific process is the same as in Example 1.

[0074] 2) Preparation of doped 0.15wt.% cobalt acetate sol

[0075] ① Use a graduated cylinder to measure 1L of absolute ethanol as a sol for later use;

[0076] ② Preparation of GTMS sol system: Slowly pour 60mL of GTMS into an appropriate amount of stirring solvent, then add excess deionized water to fully hydrolyze GTMS;

[0077] ③Preparation of TPOZ sol system: using ethyl acetoacetate as catalyst, first fully stir 13mL of ethyl acetoacetate and an appropriate amount of solvent, then slowly add 26.7mL of TPOZ; after mixing evenly, slowly add deionized water dropwise, The molar ratio of TPOZ to deionized water is 3:1;

[0078] ④The above two sol systems were respectively placed at room temperature and stirred for 0.5h;

[0079] ⑤ Mix the above two sol systems and stir evenly;

[0080] ⑥ Weighing a certain amount of cobalt acetate, fully dissolving it in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com