Toughened PBT (Polybutylene Terephthalate) engineering plastic and preparation method thereof

A technology of polybutylene terephthalate and engineering plastics, which is applied to environment-friendly and toughened polybutylene terephthalate engineering plastics and its preparation, and the field of engineering plastics. , Unable to achieve super tough" effect, poor material toughness and other problems, to achieve the effect of no flocs, simple formula and process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

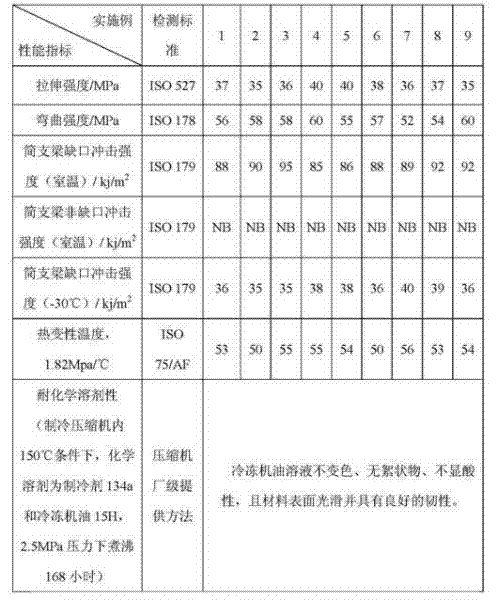

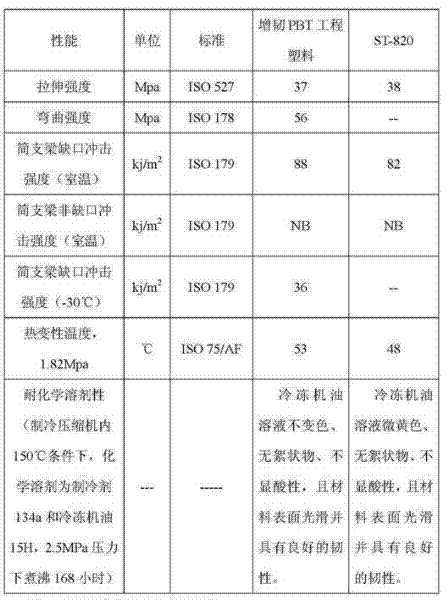

Examples

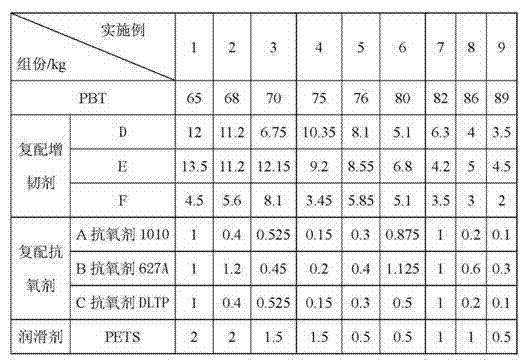

Embodiment 1-9

[0038] The preparation method of toughened polybutylene terephthalate engineering plastics in the embodiment of the present invention is as follows:

[0039] (1) Accurately weigh the polybutylene terephthalate resin, lubricant, compound antioxidant and compound toughening agent according to the formula in Table 1, and pre-mix the polybutylene terephthalate resin Dry at a temperature of 120°C to 140°C for 2 to 4 hours, and control the moisture content of the resin below 0.05%;

[0040] (2) After the dried polybutylene terephthalate resin is cooled to room temperature, it is fully mixed with lubricant, compound antioxidant and compound toughening agent through a high-speed mixer or a double-helix gas mixture for 6-8 hours. minute;

[0041] (3) Send the mixture obtained in step (2) into a twin-screw extruder for melting, plasticizing, extruding, pulling, cooling, pelletizing, and drying to obtain the product. The extrusion temperature is 220-245°C, and the head temperature of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charpy notched impact strength | aaaaa | aaaaa |

| Charpy notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com