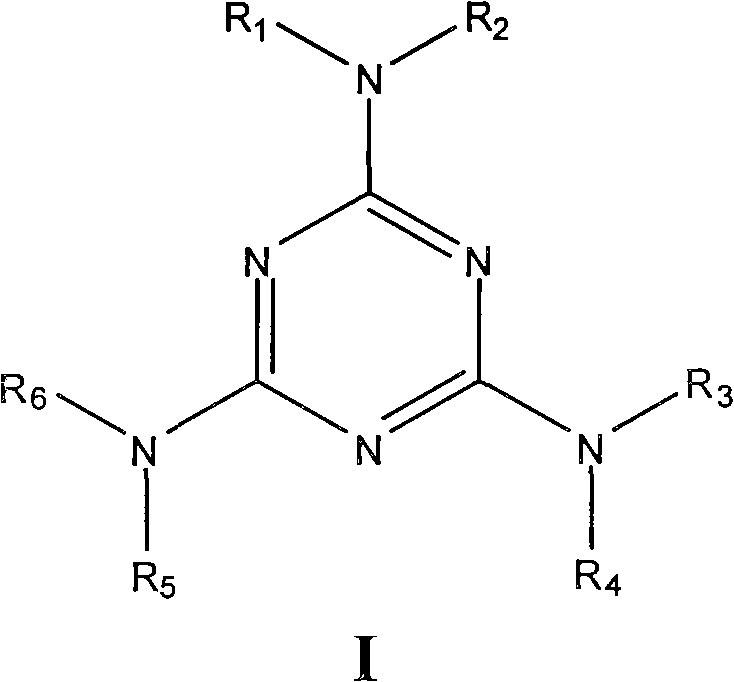

Composite flame-retardant agent containing hydroxymethylation melamine phosphide as well as preparation method and application thereof

A technology of methylolated melamine and composite flame retardant, which is applied in the field of composite flame retardant containing methylolated melamine phosphide and its preparation, can solve the problems of poor compatibility, inability to meet the requirements for the use of polymer materials, easy Problems such as moisture absorption, to achieve good compatibility, less threat to life safety, and not easy to absorb moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of methylolated melamine phosphide:

[0028] (1) Mix 100 parts by weight of melamine with 100 parts by weight of 25% formaldehyde solution, adjust pH=9 with 4 parts by weight of triethylamine, and react for methylolation at 75°C for 20 minutes, and then rotary evaporation Removal of the remaining formaldehyde to obtain methylolated melamine;

[0029] (2) Adjust step (1) The pH of the reaction system is 4, and then add 100 parts by weight of diethyl phosphite, 200 parts by weight of absolute ethanol, and 1000 parts by weight of water, adjust the temperature to 80°C, and react for 2 hours Afterwards, the precipitate is filtered, washed with deionized water to pH=7, and dried to obtain a powdery methylolated melamine silicide.

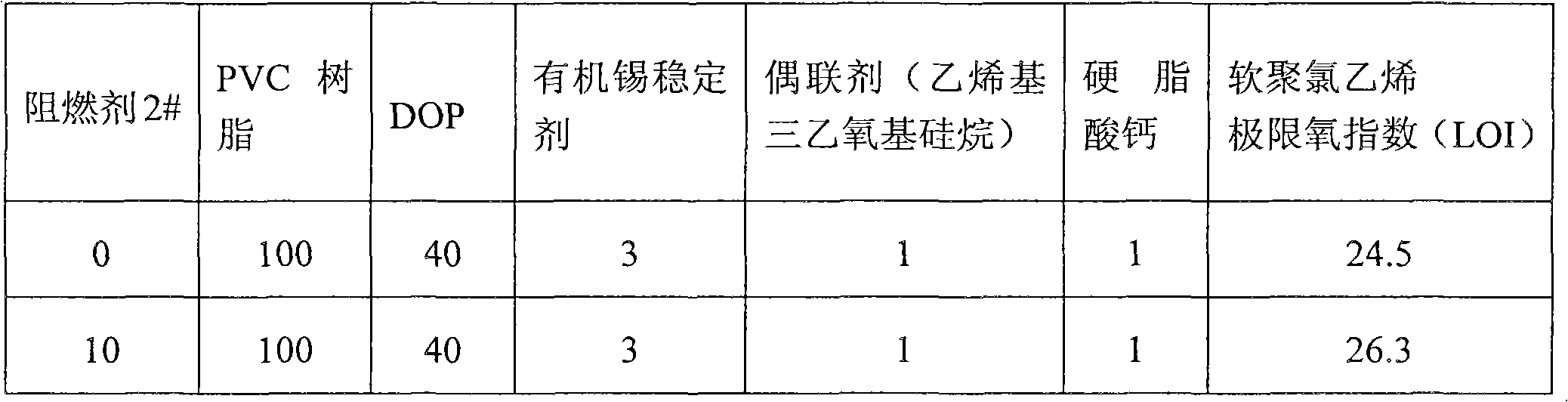

[0030] Preparation of composite flame retardant containing methylolated melamine phosphide: 100 parts by weight of methylolated melamine phosphide prepared in this example, 3 parts by weight of zinc borate, and 2 parts by weight of antimony t...

Embodiment 2

[0033] Preparation of methylolated melamine phosphide:

[0034] (1) Mix 100 parts by weight of melamine with 400 parts by weight of 20% formaldehyde solution, 0.2 parts by weight of triethylamine to adjust pH=7.5, at 85°C, methylolation reaction for 30 minutes, and then rotary evaporation to remove the remaining Formaldehyde to obtain hydroxylated melamine;

[0035] (2) Adjust step (1) pH of the reaction system = 3.8, then add 200 weight phosphoric acid and 100 weight parts of water to it, adjust the temperature to 75°C, after reacting for 5 hours, filter the precipitate, dry, and wash with deionized water Precipitate to pH=7, and dry the precipitate to obtain powdery methylolated melamine phosphide.

[0036] Preparation of composite flame retardant containing methylolated melamine phosphide: 100 parts by weight of methylolated melamine phosphide prepared in this example, 30 parts by weight of aluminum hydroxide, 40 parts by weight of antimony trioxide, 30 parts by weight Parts of ...

Embodiment 3

[0039] Preparation of methylolated melamine phosphide:

[0040] (1) Mix 100 parts by weight of melamine with 200 parts by weight of 37% formaldehyde solution, 1.8 parts by weight of triethylamine to adjust pH=8, at 60℃, methylolation reaction for 90 minutes, and then rotary evaporation to remove the remaining Of formaldehyde to obtain methylolated melamine;

[0041] (2) Adjust step (1) pH=4 of the reaction system, then add 50 parts by weight of diethyl phosphate, 200 parts by weight of absolute ethanol, and 500 parts by weight of water to it, adjust the temperature to 100°C, and react for 0.5 hours, The precipitate is filtered, dried, washed with deionized water to pH=7, and dried to obtain a powdery methylolated melamine phosphide.

[0042] Preparation of composite flame retardant containing methylolated melamine phosphide: 100 parts by weight of methylolated melamine phosphide prepared in this example, 30 parts by weight of magnesium hydroxide, 30 parts by weight of zinc borate an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy value | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com