Oxide dispersion reinforced platinum-based alloy and preparation method thereof

A dispersion-strengthening, platinum-based alloy technology, which is applied in the field of glass fiber manufacturing, can solve the problems of inability to give full play to the point dispersion strengthening of oxidizing substances, and achieve the effects of shortening the required time, good cold working performance and welding performance, and improving utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

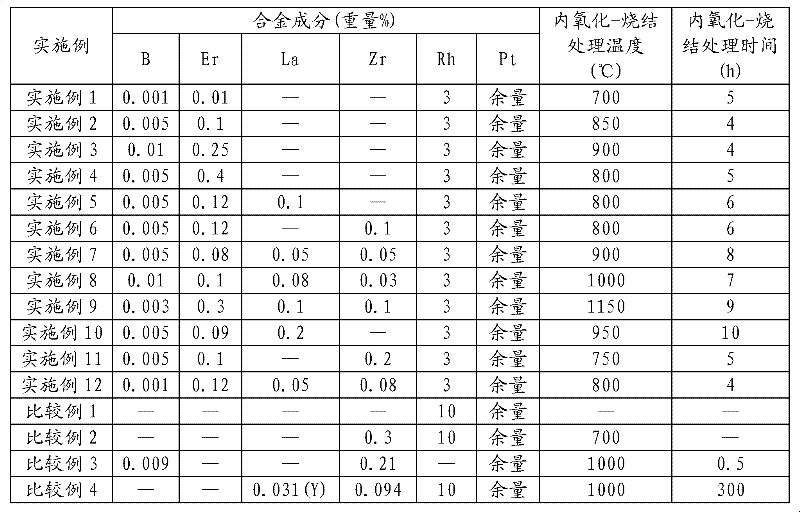

Embodiment 1

[0035] Using 4832.5 grams of platinum, 150 grams of rhodium, 5 grams of a master alloy composed of 99wt% platinum and 1wt% boron, and 12.5 grams of a master alloy composed of 96wt% platinum and 4wt% erbium as raw materials, in a medium frequency vacuum induction melting furnace A platinum-based multi-element alloy composed of 0.001wt% boron and 0.01wt% erbium is smelted, and the ingot of the platinum-based multi-element alloy is prepared into a powder by a special powder metallurgy method, and then the powder is kept at 700°C for 5 hours in an atmospheric atmosphere. Then, the boron-containing multi-phase oxide dispersion-strengthened platinum-based alloy material is prepared by hot pressing and hot forging.

Embodiment 2

[0037] Using 4700 grams of platinum, 150 grams of rhodium, 25 grams of a master alloy composed of 99wt% platinum and 1wt% boron, and 125 grams of a master alloy composed of 96wt% platinum and 4wt% erbium as raw materials, in a medium frequency vacuum induction melting furnace A platinum-based multi-element alloy composed of 0.005wt% boron and 0.10wt% erbium is smelted, and the ingot of the platinum-based multi-element alloy is prepared into a powder by a special powder metallurgy method, and then the powder is kept at 850°C for 4 hours in an atmospheric atmosphere. Then, the boron-containing multi-phase oxide dispersion-strengthened platinum-based alloy material is prepared by hot pressing and hot forging.

Embodiment 3

[0039] Using 4487.5 grams of platinum, 150 grams of rhodium, 50 grams of a master alloy composed of 99wt% platinum and 1wt% boron, and 312.5 grams of a master alloy composed of 96wt% platinum and 4wt% erbium as raw materials, in an intermediate frequency vacuum induction melting furnace A platinum-based multi-element alloy composed of 0.005wt% boron and 0.25wt% erbium is smelted, the ingot of the platinum-based multi-element alloy is prepared into a powder by a special powder metallurgy method, and then the powder is kept at 900°C for 4 hours in an atmospheric atmosphere. Then, the boron-containing multi-phase oxide dispersion-strengthened platinum-based alloy material is prepared by hot pressing and hot forging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com