Method for preparing Sn crystal whiskers

A whisker and rare earth element technology, applied in the field of new material preparation, can solve the problems of high whisker price, complicated preparation process and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

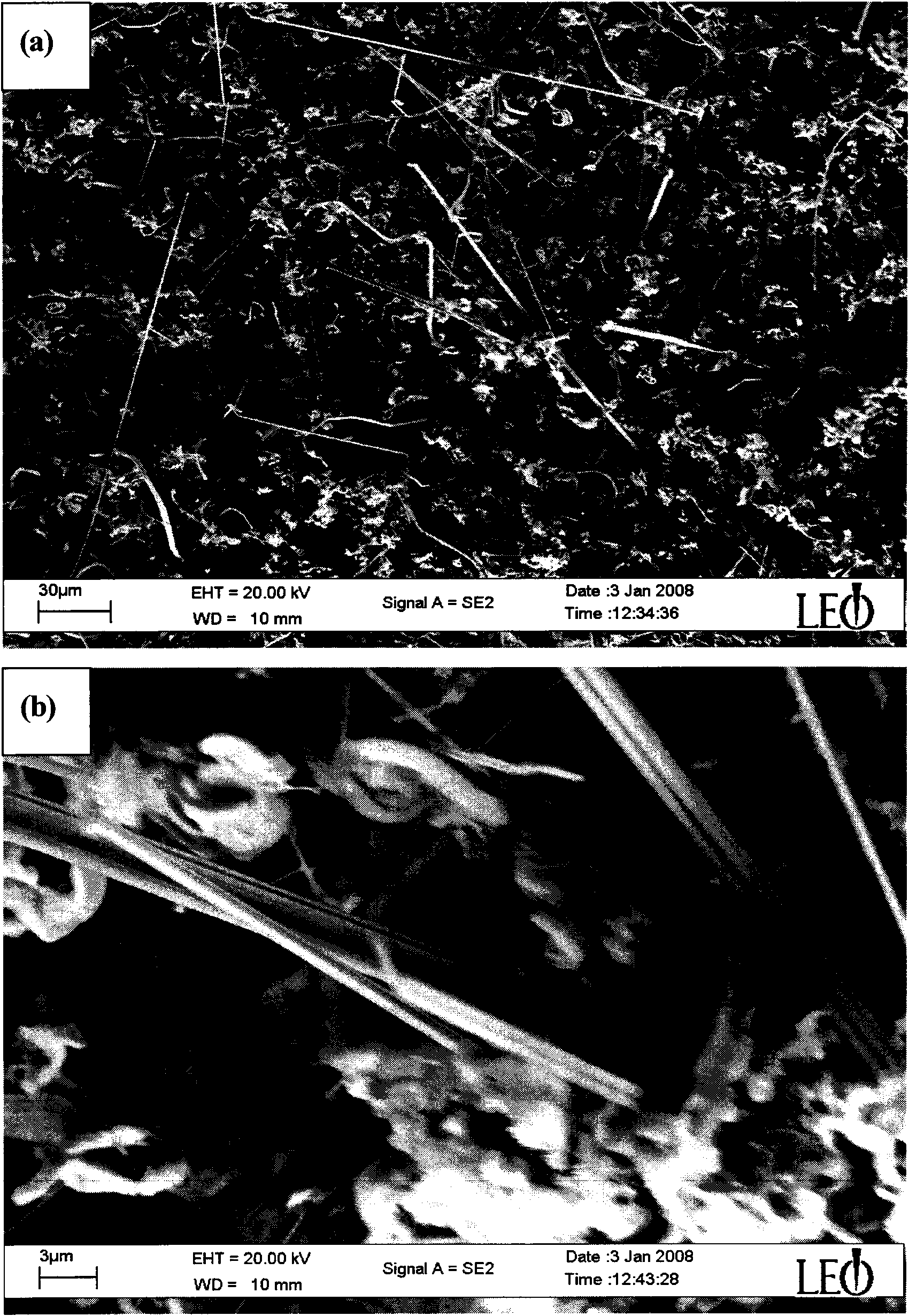

[0021] Prepare Sn-Nd alloy with Sn75at%, the rest is Nd, choose the argon shielded tungsten arc melting method to melt and smelt the alloy with the above ratio, and obtain NdSn after cooling 3 Alloy ingots of intermetallic compounds. NdSn after smelting 3 It is a brittle intermetallic compound, which is broken into a powder state by mechanical means. The particle size of the powder is 50-100 microns, and it is placed in the room temperature atmosphere as a raw material to grow whiskers. The temperature fluctuation range of the room temperature environment is ( 20~25℃), the range of humidity fluctuation is (30~45%RH, relative humidity). After the sample was naturally placed in the above environment for 26 days, dense and slender Sn whiskers grew on the surface of the raw material matrix, such as figure 1 shown.

Embodiment 2

[0023] Prepare Sn75at%, the rest is the Sn-Ce alloy of Ce, the preparation method is the same as that of Example 1, and obtains CeSn 3 Alloy ingots of intermetallic compounds. The temperature fluctuation range of the room temperature environment is (15-20° C.), and the humidity fluctuation range is (20-40% RH, relative humidity). After the sample was placed in the atmosphere at room temperature for 30 days, a large number of elongated tin whiskers grew on the surface of the raw material matrix.

Embodiment 3

[0025] Prepare Sn75at%, the rest is the Sn-La alloy of La, and preparation method is the same as embodiment 1, obtains LaSn 3 Alloy ingots of intermetallic compounds. The temperature fluctuation range of the room temperature environment is (5-10° C.), and the humidity fluctuation range is (10-20% RH, relative humidity). After the sample was placed in the atmosphere at room temperature for 50 days, a large number of elongated tin whiskers grew on the surface of the raw material matrix.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com