Semiconductor chip package structure

A chip packaging structure, semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve problems such as difficulties, achieve the effect of reducing parasitic capacitance and weakening the effect of current collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

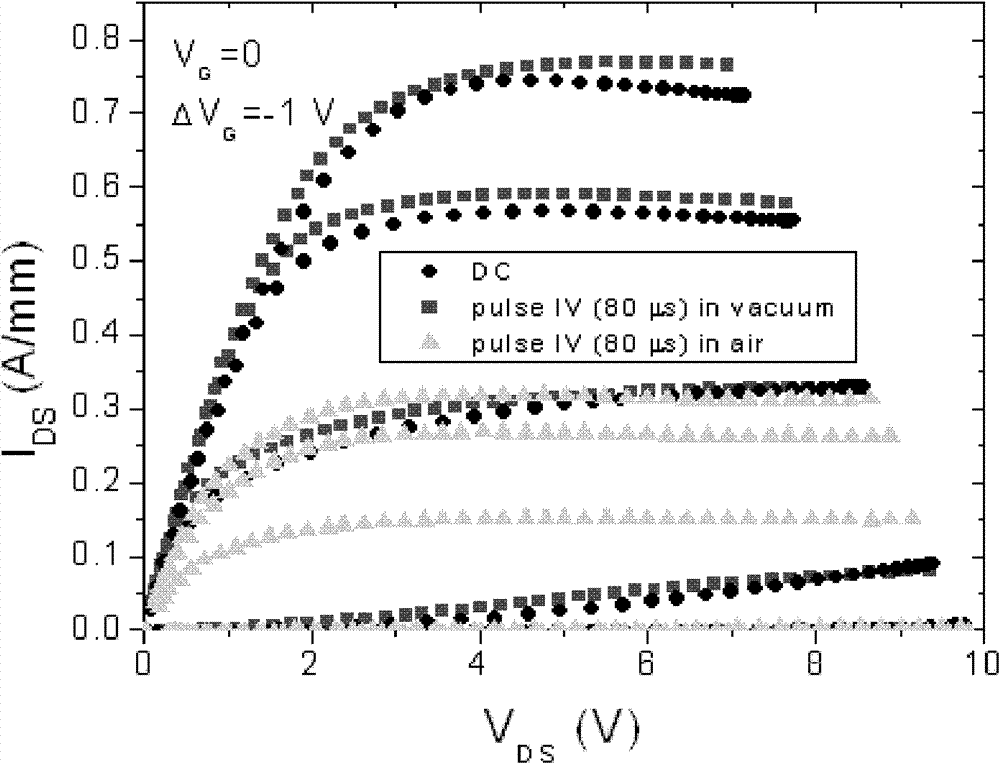

[0026] figure 1 shows the 80-µs pulsed current-voltage measurements of an AlGaN / GaN high electron mobility transistor with a 2nm SiN passivation layer in air (triangle markers) and vacuum (square markers), and also shows the dc Current and voltage measurement results (circle markers). Among them, the source-drain current (IDS) is used as a function of the source-drain voltage (VDS), and the gate voltage VG corresponding to the DC and 80 microsecond pulse current voltage is measured from the off state (-4V) to 0V, and the step size is 1V (VG= -4, -3, -2, -1, 0V). figure 1 It shows that there is a large DC-RF current collapse effect in the air environment, but there is no current collapse effect in the vacuum environment.

[0027] The same result is also observed for devices passivated by other dielectric layers, for example, devices pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com