A kind of enhanced ganhemt integrated structure and preparation method thereof

An enhanced, mesa-structured technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve device performance degradation, etching precision, thickness, surface roughness requirements are very high, and dynamic on-resistance increases and other problems, to reduce the difficulty of the preparation process, realize the normally-off characteristics, and weaken the effect of current collapse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

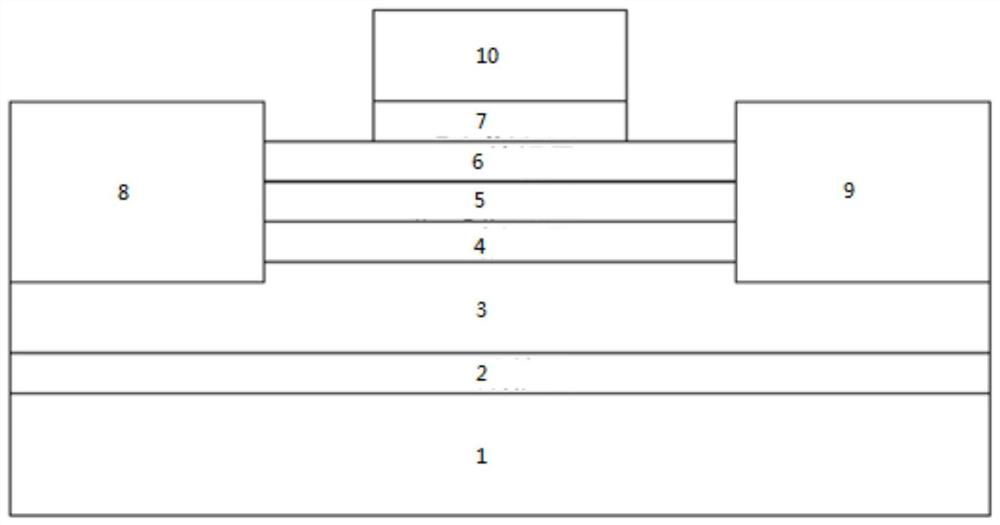

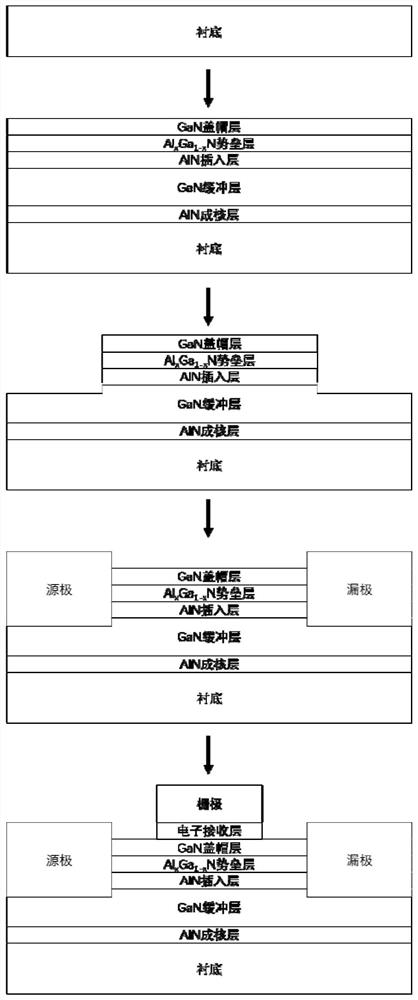

[0049] A method for preparing an enhanced GaNHEMT integrated structure according to an embodiment of the present invention includes the following steps:

[0050] 1) Use the substrate standard cleaning process to carry out inorganic and organic cleaning on the Si-based substrate successively, and dry it with nitrogen gas for later use.

[0051] 2) AlN nucleation layer, GaN buffer layer, AlN insertion layer, Al x Ga 1-x N barrier layer, GaN capping layer.

[0052] 3) Clean the GaN epitaxial material grown in step 2) with the standard process, blow it dry with nitrogen, spin-coat a layer of AZ5214 photoresist on the surface, bake the sample with spin-coated photoresist at 95°C for 90 seconds, and use the design A good mask plate is exposed to ultraviolet lithography for 4s, and developed for 30s to remove the exposed photoresist, leaving the pattern of the mesa area. Harden the film on a hot plate at 120°C for 120s.

[0053] 4) Place the photoetched sample in the sample chamb...

Embodiment 2

[0058] A method for preparing an enhanced GaNHEMT integrated structure according to an embodiment of the present invention includes the following steps:

[0059] 1) Use the substrate standard cleaning process to perform inorganic and organic cleaning on the GaN substrate successively, and dry it with nitrogen gas for later use.

[0060] 2) AlN nucleation layer, GaN buffer layer, AlN insertion layer, Al x Ga 1-x N barrier layer, GaN capping layer.

[0061] 3) Clean the grown GaN epitaxial material with standard process, dry it with nitrogen gas, spin-coat a layer of KXN5735-LO photoresist on the surface of the sample, and bake the GaN sample with spin-coated photoresist at 95°C for 90 seconds , use the designed mask to expose to UV lithography for 2s, develop for 25s to remove the exposed photoresist, and leave the pattern of the etched area. Harden the remaining photoresist at 120°C for 120s.

[0062] 4) Place the photolithographic sample in the sample chamber of the ion b...

Embodiment 3

[0067] In the embodiment of the present invention, the difference from embodiment 1 is only:

[0068] The substrate material is diamond, with a size of 1 to 12 inches; the material of the electron receiving layer is V 2 o 5 , the thickness of the AlN nucleation layer is 2-5 nm, the thickness of the GaN buffer layer is 1-5 μm, the thickness of the AlN insertion layer is 0-5 nm, the Al x Ga 1-x The thickness of the N barrier layer is 2-30nm, and the thickness of the GaN capping layer is 0-2nm.

[0069]The materials of the source electrode and the drain electrode are Ti, Al and Ni, and the materials of the gate electrode are Ni, Au and Pt.

[0070] Deposit materials on the surface of GaN cap layer and GaN buffer layer of the mesa structure to form source and drain; among them, the ohmic contact should cover part of GaN cap layer, part of buffer layer, and the N 2 Annealing in a mixed atmosphere with Ar, the annealing temperature is 1000°C, and the annealing time is 2 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com