Adhesive of self-adhesive layer adopting multielement monomer copolymerization and preparation method thereof

A technology of multiple monomers and adhesives, applied in the direction of ester copolymer adhesives, adhesives, adhesive types, etc., can solve the problem of detachment of the adhesive force between the coil and the substrate, decreased adhesive performance, and low adhesive strength, etc. problems, to achieve the effect of improving product quality and service life, improving bonding strength, and convenient and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

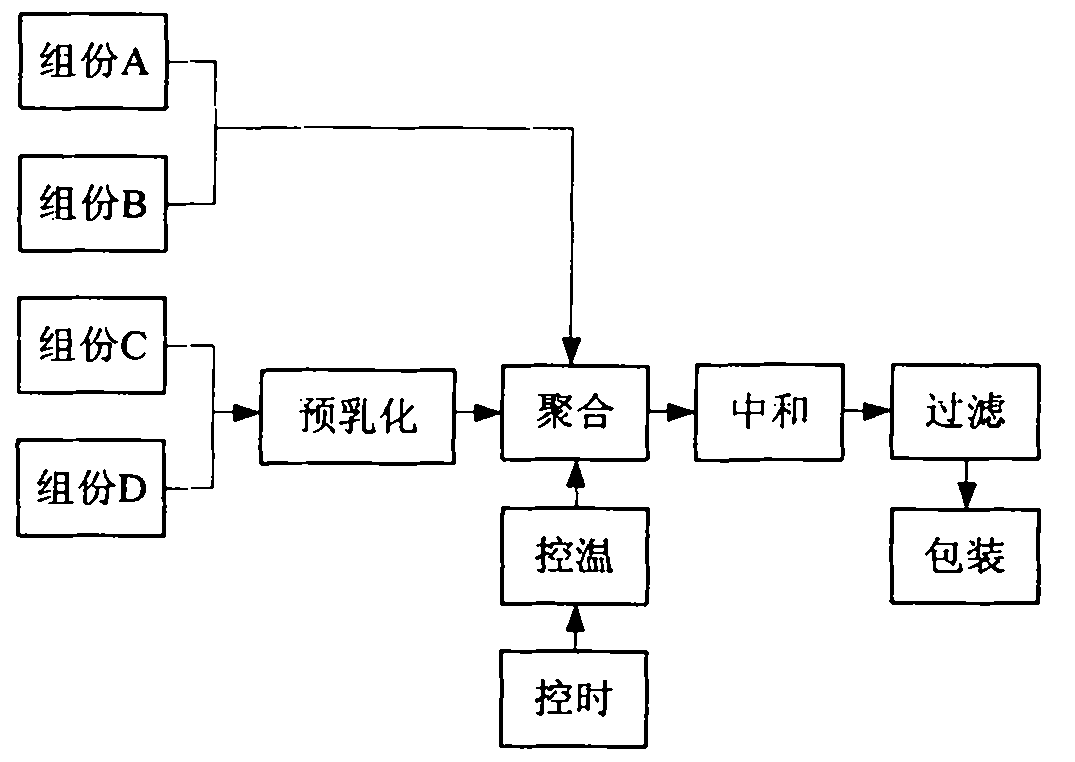

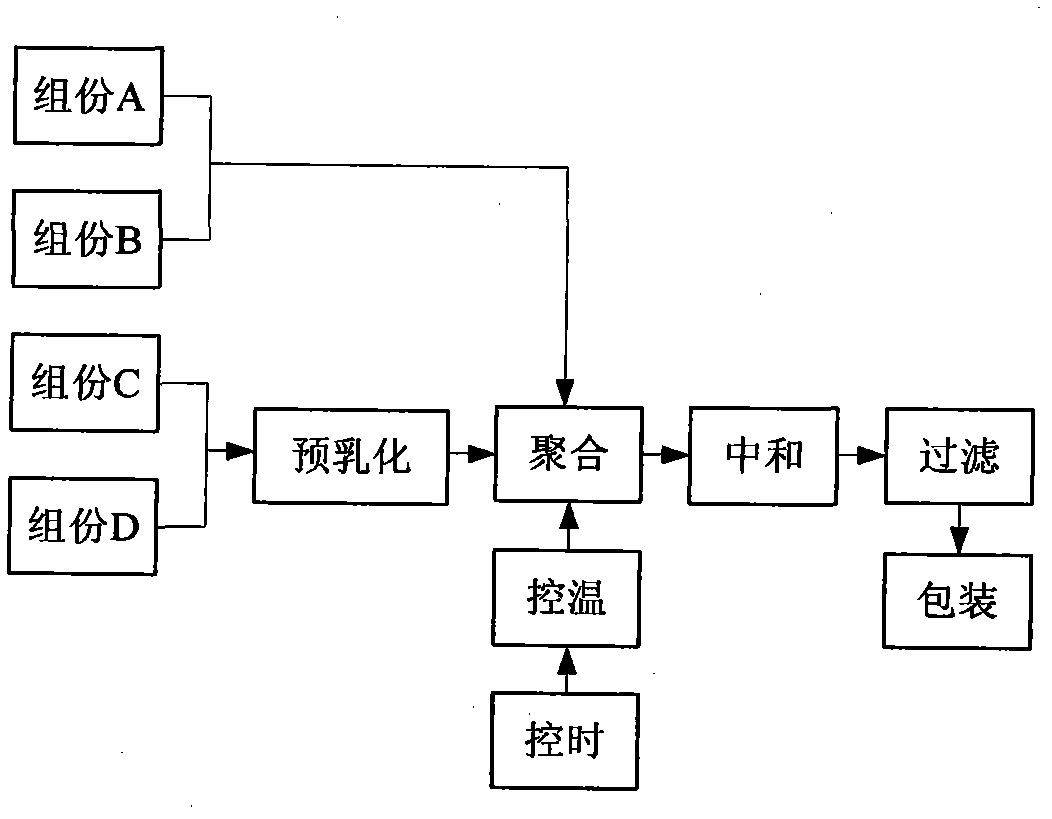

[0064] With reference to Fig. 1, according to the production process shown in Fig. 1, prepare the adhesive agent in the self-adhesive layer tape that is used on the waterproof coiled material of the present invention, concrete steps are as follows:

[0065] 1) First, weigh according to the adhesive formula:

[0066] Component A is: measure 110.0 parts by weight of deionized water;

[0067] Component B is: measure and mix 15.0 parts by weight of deionization, 1.0 parts by weight of sodium persulfate and 0.2 parts by weight of polymerization agent;

[0068] Component C is: measure and mix 120.0 parts by weight of deionized water, 0.5 parts by weight of potassium persulfate, 3.8 parts by weight of polymerization agent and 1.5 parts by weight of anhydrous sodium sulfate;

[0069] Component D is: weigh 200.0 parts by weight of butyl acrylate, 5.0 parts by weight of methacrylic acid, 0.9 parts by weight of gum rosin, 18.0 parts by weight of vinyl acetate, 5.0 parts by weight of met...

Embodiment 2

[0073] 1) Adhesive formulation

[0074] Component A is: 105.0 parts by weight of deionized water;

[0075] Component B is: 20.0 parts by weight of deionization, 1.0 parts by weight of sodium persulfate and 0.5 parts by weight of polymerization agent;

[0076] Component C is: 123.5 parts by weight of deionized water, 0.5 parts by weight of ammonium persulfate, 3.0 parts by weight of polymerization agent and 1.5 parts by weight of anhydrous sodium sulfate;

[0077] Component D is: 230.0 parts by weight of butyl acrylate, 5.0 parts by weight of methacrylic acid, 1.3 parts by weight of gum rosin and 10.0 parts by weight of vinyl acetate, first dissolve 1.3 parts by weight of gum rosin in component D, and then mix with the Mix components C well, and pre-emulsify at a speed of 500r / min for 30 minutes to obtain a milky white uniform pre-emulsion;

[0078] Adhesive Synthesis:

[0079] In a four-necked flask equipped with a stirrer, a thermometer, a dropping bottle and a self-temper...

Embodiment 3

[0081] 1) Adhesive formulation

[0082] Component A is: 115.0 parts by weight of deionized water;

[0083] Component B is: 21.0 parts by weight of deionization, 1.0 parts by weight of sodium persulfate and 0.3 parts by weight of polymerization agent;

[0084] Component C is: 110.0 parts by weight of deionized water, 0.5 parts by weight of ammonium persulfate, 3.5 parts by weight of polymerization agent and 1.0 parts by weight of anhydrous sodium sulfate;

[0085] Component D is: 207.0 parts by weight of butyl acrylate, 5.0 parts by weight of methacrylic acid, 5.0 parts by weight of vinyl acetate, 5.0 parts by weight of terpene resin and 3.0 parts by weight of methyl methacrylate. Dissolve in component D, then mix with the prepared component C, and pre-emulsify at a speed of 350r / min for 50 minutes to obtain a milky white uniform pre-emulsion;

[0086] 2). Adhesive synthesis:

[0087] In a four-necked flask equipped with a stirrer, a thermometer, a dropping bottle and a self...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com