Perpendicular magnetic anisotropic multi-layered film

An anisotropic and perpendicular magnetic technology, applied in the direction of the magnetic layer, can solve the problems of spin scattering enhancement, high magnetoresistance, and difficult magnetic moment, so as to reduce the reversal field or reversal current, improve the magnetoresistance, The effect of reducing the coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

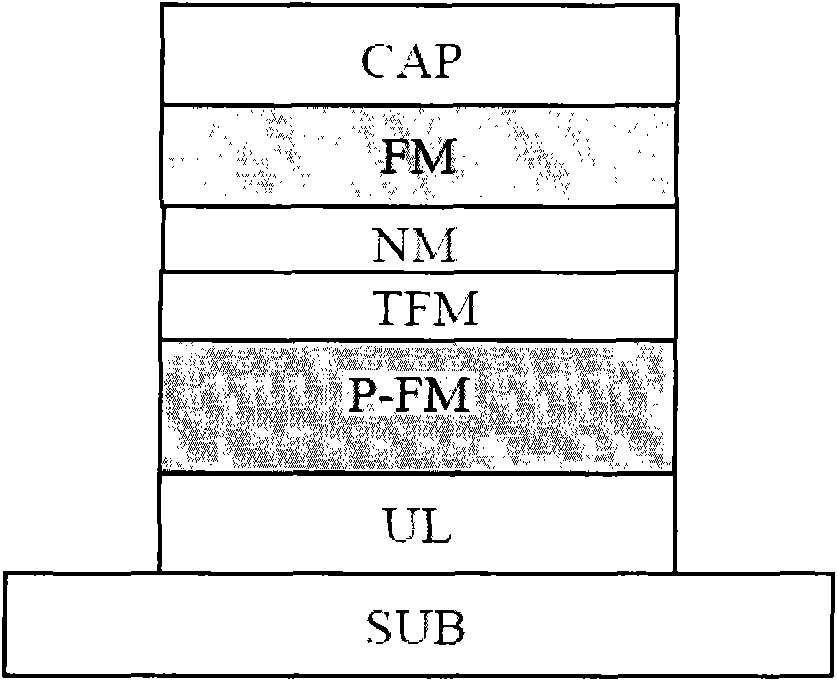

[0062] Such as figure 2 As shown, the structure of the multilayer film with perpendicular magnetic anisotropy in this embodiment is as follows: SUB / UL / P-FM / TFM / NM / FM / CAP. The multilayer film structure can be used as the core unit of giant magnetoresistance devices.

[0063] The preparation method of the multilayer film with perpendicular magnetic anisotropy of the present embodiment is as follows:

[0064] 1) Choose a Si-SiO with a thickness of 1mm 2 The substrate is used as the substrate SUB, and the vacuum on the magnetron sputtering equipment is better than 2×10 -6 Pa, the deposition rate is 0.1nm / s, and the argon pressure during deposition is 0.07Pa, and a 10nm Pt bottom layer UL is deposited on the substrate;

[0065] 2) On the magnetron sputtering equipment, the vacuum is better than 2×10 -6 Pa, the deposition rate is 0.1nm / s, and the argon pressure is 0.07Pa. A magnetic layer [Pt(0.6nm) / Co(0.4nm)] with a vertical magnetic anisotropy of 55nm is deposited on the bott...

Embodiment 2

[0072] Such as Figure 5 As shown, the structure of the multilayer film with perpendicular magnetic anisotropy provided in this embodiment is as follows: SUB / UL / P-FM / TFM / I / FM / CAP. The multi-layer film structure can be used as the core unit of the tunnel junction magnetoresistive device.

[0073] The preparation method of the multilayer film with perpendicular magnetic anisotropy of the present embodiment is as follows:

[0074] 1) Choose a Si-SiO with a thickness of 1mm 2 The substrate is used as the substrate SUB, and the vacuum on the magnetron sputtering equipment is better than 2×10 -6 Pa, the deposition rate is 0.1nm / s, and the argon pressure during deposition is the condition of 0.07Pa, the bottom layer UL of Ta(5nm) / Ru(10nm) / Ta(5nm) is deposited on the substrate;

[0075] 2) On the magnetron sputtering equipment, the vacuum is better than 2×10 -6 Pa, the deposition rate is 0.1nm / s, and the argon pressure is 0.07Pa, the magnetic layer structure [Pt(0.7nm) / Co(1.2nm)] ...

Embodiment 3~8

[0082] Embodiment 3~8 is that the structure that is used for giant magnetoresistance device is the multilayer film of SUB / UL / P-FM / TFM / NM / FM / CAP (such as figure 2 Shown), the concrete material that each layer of described multilayer film adopts and the thickness of each layer are as shown in Table 1.

[0083] ("Metal layer" in the following table represents a metal layer that together constitutes a composite magnetic layer with a magnetic layer having perpendicular magnetic anisotropy)

[0084] Table 1

[0085]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com