Preparation method of modified and micronized 2-mercaptopyridine oxide zinc salt

A technology of pyrithione and zinc oxide, which is applied in the field of preparation of modified micro-sized 2-pyridine oxide zinc salt, can solve problems such as difficulties in the preparation method, achieve rich performance, overcome difficulties in post-processing, and have low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

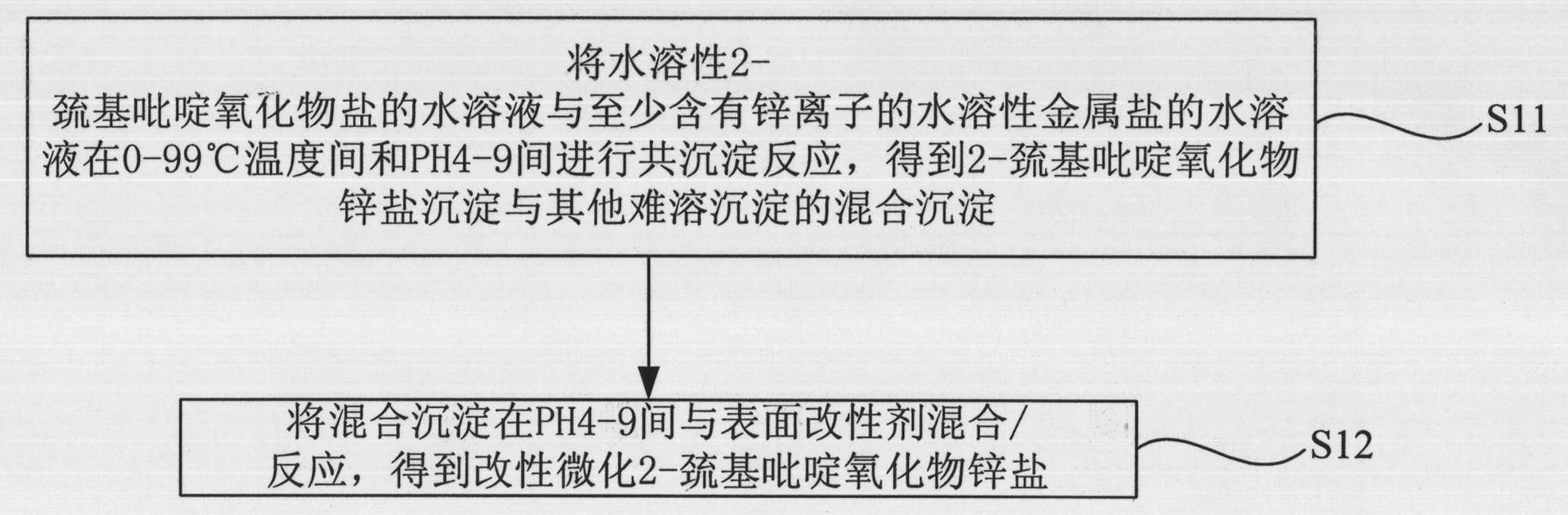

[0030] see figure 1 , a kind of preparation method of micronized 2-mercapto pyrithione zinc salt, comprises the following steps:

[0031] S11: Co-precipitate an aqueous solution of a water-soluble 2-mercapto pyrithione salt and an aqueous solution of a water-soluble metal salt containing at least zinc ions at a temperature of 0-99°C and a pH of 4-9 to obtain 2-mercaptopyridine Mixed precipitation of zinc salt precipitation and other insoluble precipitation;

[0032] In this step, the co-precipitation reaction is preferably carried out between pH5-8, most preferably between pH7-8. Other insoluble precipitates refer to inorganic or organic precipitates containing polyvalent metal ions whose dissolved mass in 100 g of water is less than 1 gram, more preferably less than 0.1 gram, and most preferably less than 0.01 gram. After the co-precipitation reaction, the content of the mixed precipitate in the mother liquor after the reaction is 0.01%-30%, most preferably 0.5%-10%. And t...

Embodiment 1

[0051] At room temperature of 25°C, add 10 ml of sodium bicarbonate solution containing 0.1 mol / L of 2-mercaptopyridine oxide and 0.05 mol / L of sodium bicarbonate to a 50-ml beaker, put it into a magnetic rotor coated with PTFE, and put the SH05-3 constant temperature magnetic stirrer (Shanghai Minhang Hongpu Instrument Factory) adjust the speed to the maximum. Then, 10 ml of an aqueous solution of zinc sulfate containing 0.11 mol / L (adjusted to pH 4-4.5 with sulfuric acid) was added dropwise from the top of the center of the vortex formed by the magnetic rotor within 1 minute. After the dropwise addition, the stirring was continued for 30 minutes and then stopped.

[0052] The suspension containing zinc pyrithione and insoluble inorganic zinc precipitate was filtered through filter paper. Under the intense stirring of vacuuming, the obtained filter cake was added to 150 milliliters containing 20% (weight ratio) ammonium lauryl alcohol ether sulfate and ammonium lauryl alco...

Embodiment 2

[0055] At room temperature of 25°C, add 10 ml of sodium bicarbonate solution containing 0.1 mol / L of 2-mercaptopyridine oxide and 0.05 mol / L of sodium bicarbonate to a 50-ml beaker, put it into a magnetic rotor coated with PTFE, and put the SH05-3 constant temperature magnetic stirrer (Shanghai Minhang Hongpu Instrument Factory) adjust the speed to the maximum. Then, 10 ml of an aqueous solution of zinc sulfate containing 0.11 mol / L (adjusted to pH 4-4.5 with sulfuric acid) was added dropwise from the top of the center of the vortex formed by the magnetic rotor within 1 minute. After the dropwise addition, the stirring was continued for 30 minutes and then stopped.

[0056] Slowly drop 4.8 ml of 0.2mol / L dilute hydrochloric acid solution into the reaction mother liquor, and control the pH value of the solution not to be lower than 4.5 during the dropwise addition, after the dropwise addition is completed. The obtained suspension was filtered with filter paper and washed and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com