Low temperature bonding electronic adhesives

An adhesive and adhesive film technology, applied in conductive adhesives, film/sheet adhesives, non-polymer organic compound adhesives, etc., can solve the lack of strong adhesion of flexible circuits, etc. problem, to achieve ideal peel adhesion and bond reliability, excellent adhesion, ideal reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

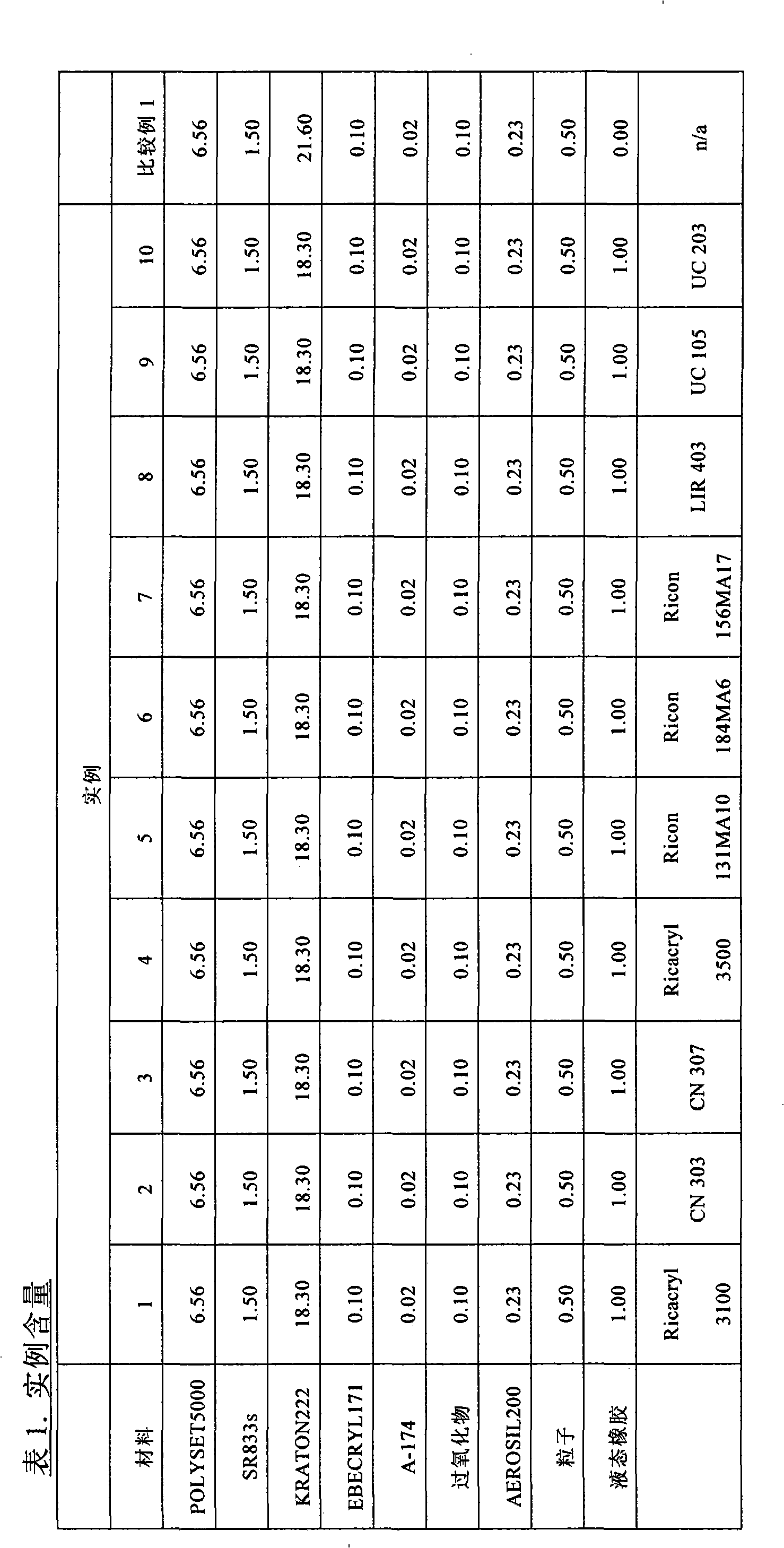

example 1-10 and comparative example 1

[0067] Examples 1-10 and Comparative Example 1 (CE-1) :

[0068] Binder solutions were prepared and used to prepare films as described below. The ingredients listed in the table below were combined in a small jar and mixed for approximately five minutes with an air driven mixer equipped with a high shear blade. The solution was degassed by placing the jar in a vacuum chamber at ambient temperature until bubbling ceased. The degassed solution was coated onto a silicone-treated polyethylene terephthalate (PET) film using a knife coater. The coating solution was dried for 5 minutes in a forced air oven set at 50°C. The dried adhesive film thickness was about 20 μm.

[0069] The films coated from Examples 1 to 10 all had significantly increased tack compared to Comparative Example 1. Table 2 (shown below) shows the peak exotherm temperature measured by DSC and the 90 degree peel adhesion measured after bonding the flex circuit to ITO coated glass using the ACF example, using...

example 11-14 and comparative example 2

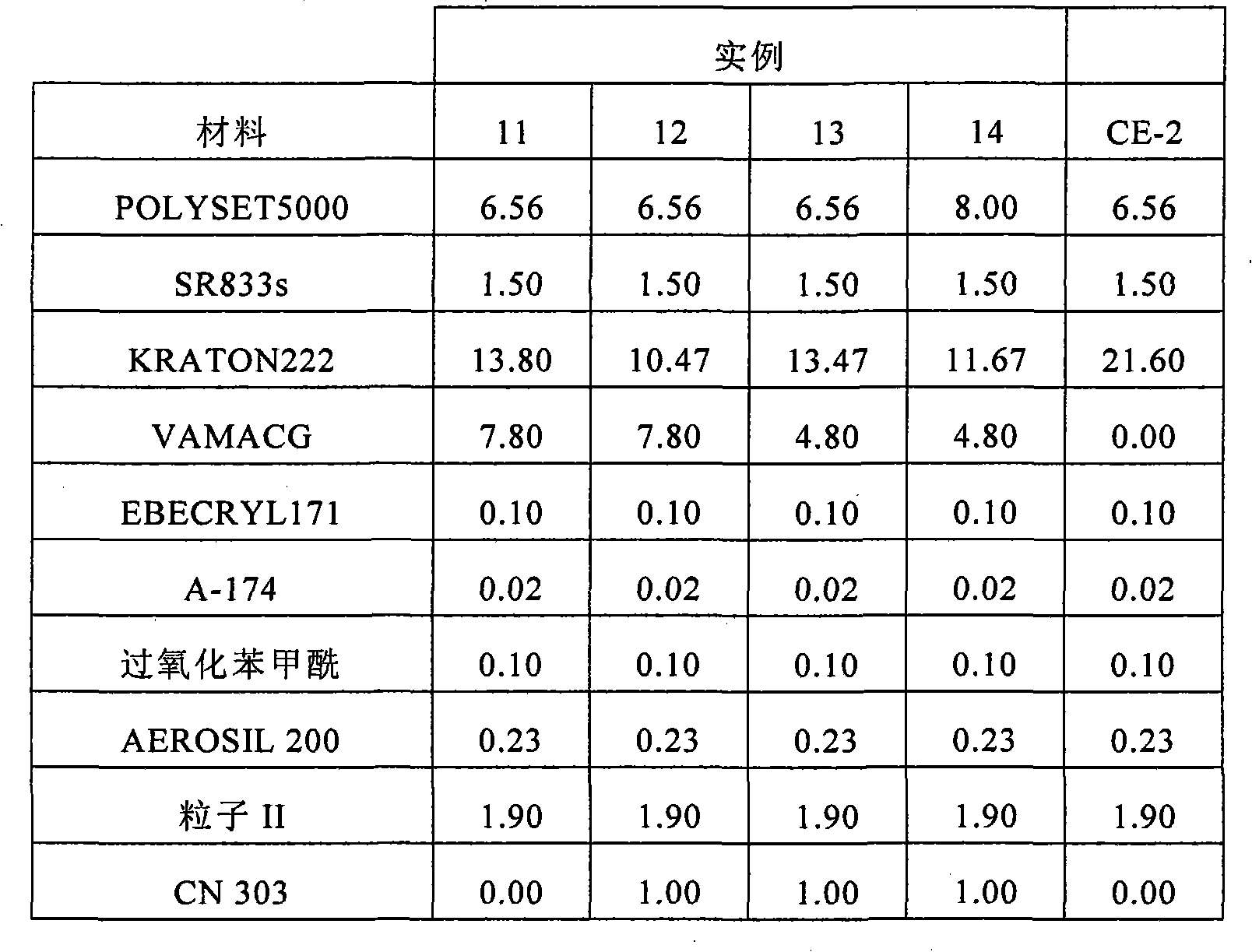

[0073] Examples 11-14 and Comparative Example 2 (CE-2) :

[0074] Adhesive solutions were prepared and films were prepared as in Examples 1-10, except that the components listed in Table 3 were used and then coated using a knife coater with a 6 mil (152 μm) gap to PET release liner. The coated film was then dried in a forced air oven at 50° C. for 5 minutes to produce a film with a thickness of 40 μm.

[0075] Table 3. Example content

[0076]

[0077] The films coated from Examples 11-14 all had significantly increased tack compared to CE-2, with the films from 12, 13 and 14 comprising liquid rubber, CN 303 (Sartomer) having the highest level of tack . Table 4 compares the peak exotherm temperature measured by DSC and the 90 degree peel adhesion measured after bonding the flex circuit to the PC board using the ACF example under the following bonding conditions: 140°C at 3MPa 5 seconds, 160°C for 5 seconds at 3MPa, and 170°C for 7 seconds at 3MPa.

[0078] Table ...

example 15-18 and comparative example 3

[0082] Examples 15-18 and Comparative Example 3 (CE-3) :

[0083] Adhesive solutions were prepared as in Examples 1-10 and used to make films, except that the components listed in Table 5 were used and then coated onto PET release liners using a knife coater. The coated film was then dried in a forced air oven at 50° C. for 5 minutes to produce a film with a thickness of 20 μm.

[0084] First, tape (410B from 3M Company) was applied to the platen of an IMASS 2000 (Instrumentors, Strongsville, OH) using hand pressure and the paper liner was removed from the tape to expose the Second adhesive side of the tape. The coating formulation with the exemplary anisotropic conductive film (ACF) coated side on the underside was applied to the 410B tape and rubbed down by hand. The liner was pulled back, exposing the ACF attached to the 410B strip to create a leader gripped by the tool pull bar. The peel test was started and the force required to remove the liner from the one inch (25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com