Processing method for high anti-reflective glass for packaging solar battery pack

A technology of solar cells and processing methods, applied in the direction of electrical components, sustainable manufacturing/processing, circuits, etc., can solve the problems of poor adhesion on glass surfaces, poor film layer uniformity, and low stability of sol, and achieve particle prevention Agglomeration, not easy to erase damage and peeling, strong anti-friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

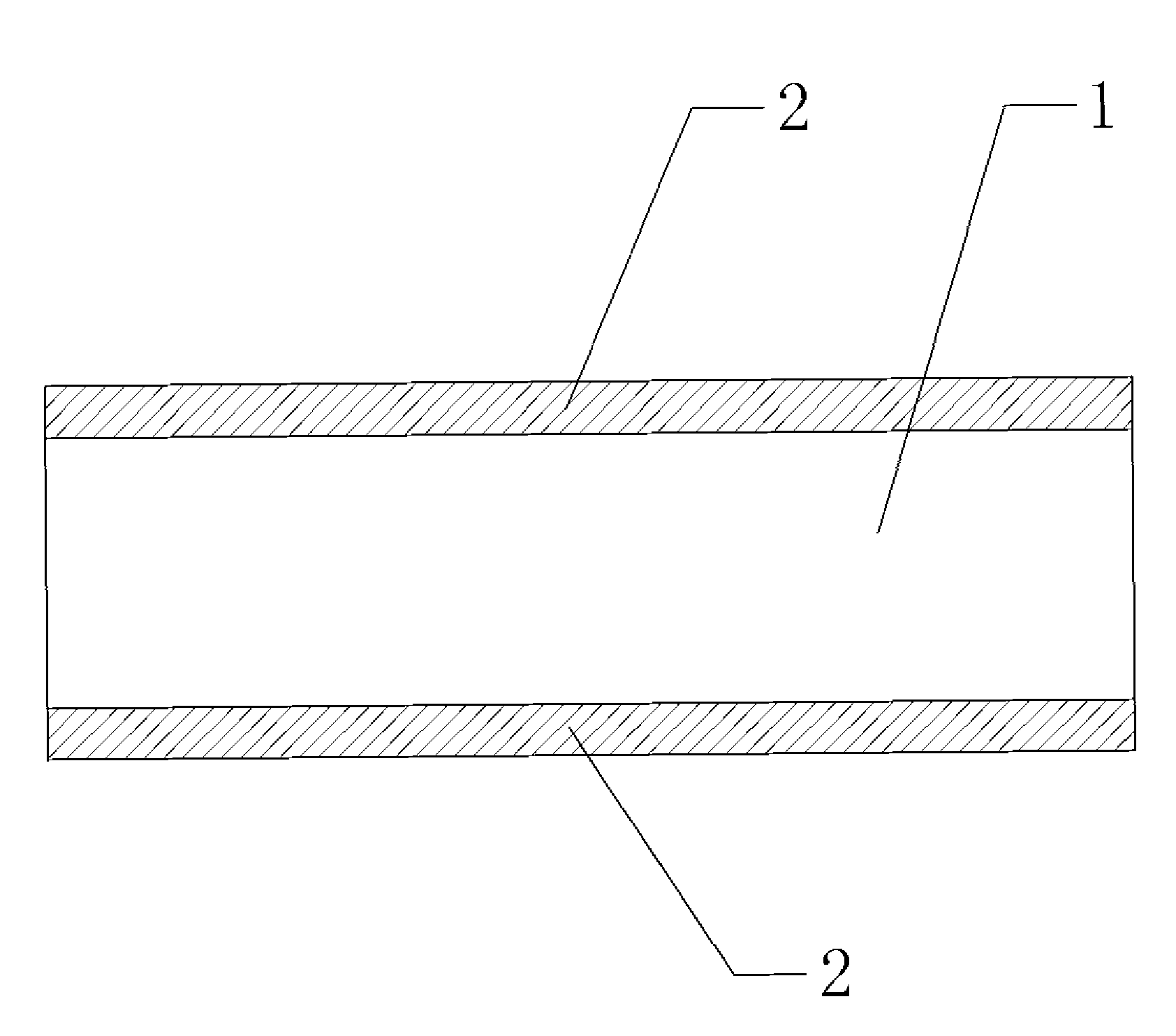

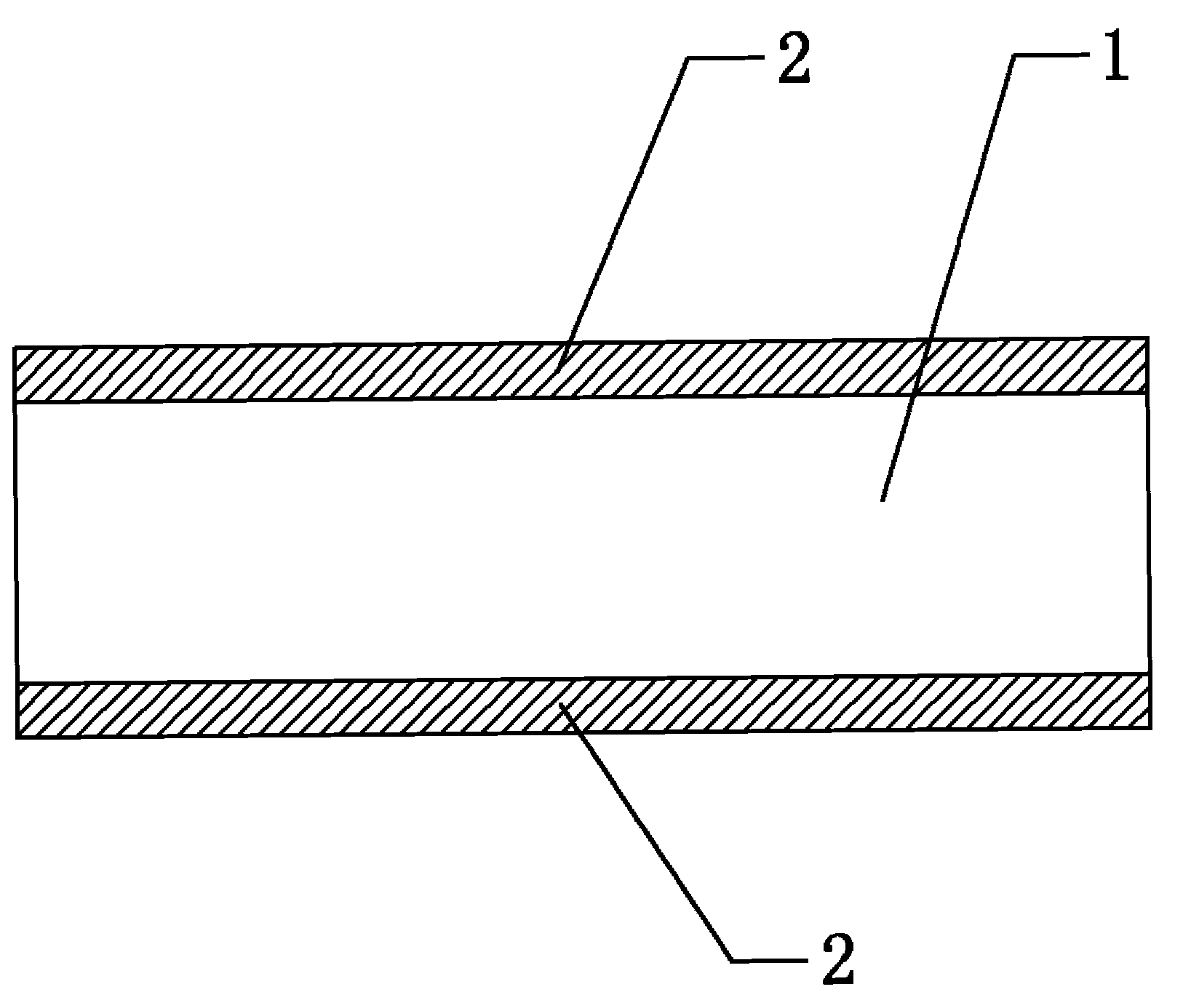

[0018] At room temperature, dissolve 1730ml of tetraethyl orthosilicate in 18030ml of absolute ethanol, under vigorous stirring, add 310ml of deionized water and 30ml of hydrochloric acid with a concentration of 0.12mol / L in sequence, control the pH value to 2.4, and then add 2 gram of lithium magnesium silicate, sealed and stirred for 3 hours, and aged for 15 days for later use; SiO 2 The anti-reflection coating solution is placed in an ultrasonic oscillator for 10 minutes, and the glass substrate is made of 3.2mm ultra-clear float glass, which is coated on both sides by the vertical pulling method. The pulling speed is 500mm / min, and then the Drying; tempering the coated glass, the tempering temperature is 700°C, the high temperature heating time is 170 seconds, and the enhanced wind pressure is 90%, and finally the high anti-reflection coating solar cell module packaging glass is obtained. The light transmittance of the packaging glass in the 400nm-1000nm band reaches an av...

Embodiment 2

[0020] At room temperature, dissolve 1,730ml of tetraethyl orthosilicate in 18,030ml of absolute ethanol. Under vigorous stirring, add 310ml of deionized water and 17ml of hydrochloric acid with a concentration of 0.12mol / L in order to control the pH value to 3.3, and then add 3 grams of lithium magnesium silicate, sealed and stirred for 3 hours, and aged for 15 days for later use; SiO 2 The anti-reflection coating solution was placed in an ultrasonic oscillator for 10 minutes, and the glass substrate was made of 3.2mm ultra-clear float glass, and the double-sided coating was applied to the substrate by the vertical pulling method. The pulling speed was 500mm / min, and then the Drying under low temperature; temper the coated glass, the tempering temperature is 700°C, the high temperature heating time is 170 seconds, and the enhanced wind pressure is 90%, and finally the high anti-reflection coating solar cell module packaging glass is obtained. The packaging glass has an averag...

Embodiment 3

[0022] At room temperature, dissolve 1,730ml of tetraethyl orthosilicate in 8,650ml of absolute ethanol. Under vigorous stirring, add 519ml of deionized water and 9ml of hydrochloric acid with a concentration of 0.12mol / L in sequence to control the pH value to 2, and then add 5 grams of lithium magnesium silicate, sealed and stirred for 2 hours, and aged for 11 days for later use; SiO 2The anti-reflection coating solution is placed in an ultrasonic oscillator for 5 minutes, and the glass substrate is made of 3.2mm ultra-clear float glass, which is coated on both sides by the vertical pulling method. The pulling speed is 500mm / min, and then the Drying; temper the coated glass with a tempering temperature of 800°C, a high-temperature heating time of 170 seconds, and an enhanced wind pressure of 95%, and finally obtain a highly anti-reflection coated solar cell module packaging glass. The average light transmittance of the packaging glass in the 400nm-1000nm band reaches 95.2%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com