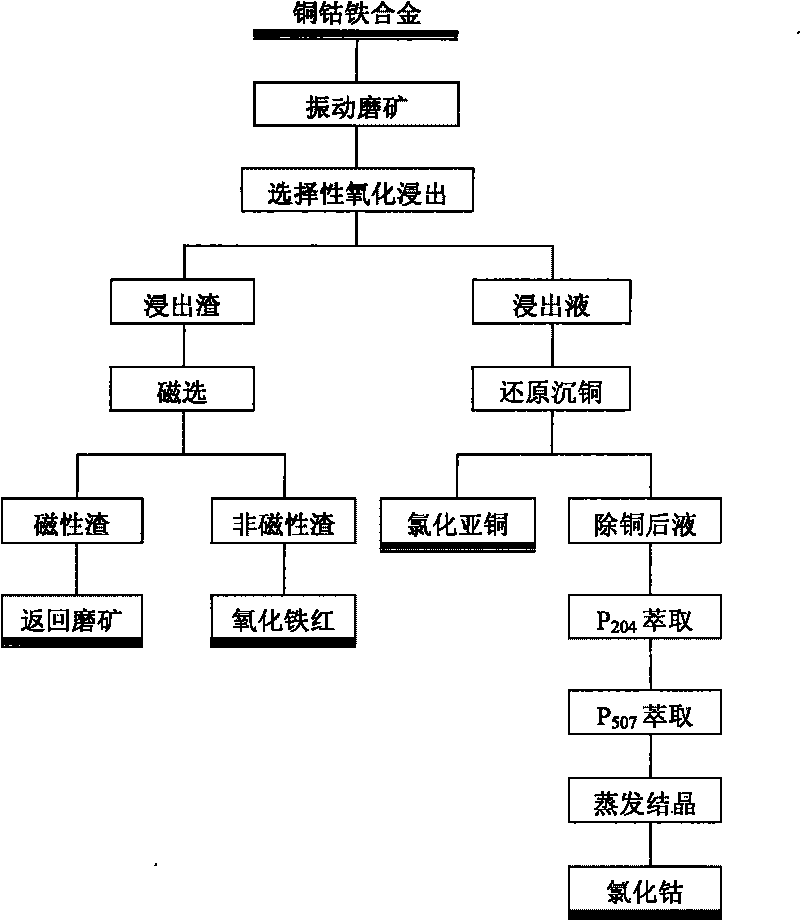

Production process for comprehensively recovering valuable metal of copper, cobalt and iron alloy

A valuable metal and production process technology, applied in the field of hydrometallurgy, can solve the problems of high equipment requirements, large consumption of neutralizing alkali, high cost, etc., and achieve a wide range of initial temperature, good comprehensive recovery effect, and high reaction speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Weigh 100g of -100 mesh white metal powder into a self-made PP beaker, add 600ml of water, start stirring, add the required theoretical amount of fluoride ions, start slowly adding 48mL of concentrated sulfuric acid, and stir for 1.5 hours , use a separatory funnel to slowly add a solution made of 70g of sodium chlorate, the speed of adding the sodium chlorate solution is based on the temperature of the reaction process at 90-95°C, after the addition of sodium chlorate, continue to keep the temperature greater than 85°C and stir for 1.5 After h, solid-liquid separation was carried out, and the filter cake was washed 2-3 times with acidified water with a pH value of 2.5, and then the content of related elements in the filtrate and filter residue was analyzed. The test results are shown in Table 2.

[0048] The impact of table 2 acid amount on the leaching rate of valuable metals

[0049]

Embodiment 2

[0050] Embodiment 2: 1 ton, 100 purpose white metal powders are put into the company's production with 7.5m 3 In the PP reactor, add 3m 3 Water, start stirring, add the required theoretical amount of fluoride ions (theoretical amount of fluoride ions participate in the reaction 2Si+12F according to soluble silicon - +8H + =2SiF 6 2- +4H 2 ↑ calculation), add sulfuric acid 450L, react after 1.5 hours, add sodium chlorate solution by the speed of 400L / h through the flowmeter, the total consumption of sodium chlorate is 700kg, when the temperature in the reaction process is greater than 90 ℃, add a certain amount of Water, if the total volume in the kettle does not exceed 6m 3 As a standard, react for 4 hours, press filter, and wash the filter cake twice with acidified water slurry with a pH value of 2.5.

[0051] Table 3 Analysis results of related elements in filtrate and slag

[0052]

Embodiment 3

[0053] Embodiment 3: put 1 ton, 100 purpose white metal powders into company production and use 7.5m 3 PP reactor, add 2m 3 Water, add 60kg ammonium bifluoride, start stirring, add 770L of 31% industrial hydrochloric acid, after reacting for 1.5h, add sodium chlorate solution at a speed of 400L / h through the flow meter, the total consumption of sodium chlorate is 700kg, when the reaction process Add a certain amount of water when the temperature is higher than 90°C, so that the total volume in the kettle does not exceed 6m 3 As a standard, react for 4 hours, press filter, and wash the filter cake twice with acidified water slurry with a pH value of 2.5.

[0054] Table 4 Analysis results of related elements in filtrate and slag

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com