Method for synthesizing presintering hard ferrite material

The technology of a hard ferrite and a synthesis method is applied in the synthesis of hard ferrite pre-sintered materials and the field of magnetic material preparation, which can solve the problems of large heat dissipation of the rotary kiln body and high energy consumption in the reaction process, and is suitable for batch production. The effect of short production and synthesis time and low synthesis energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

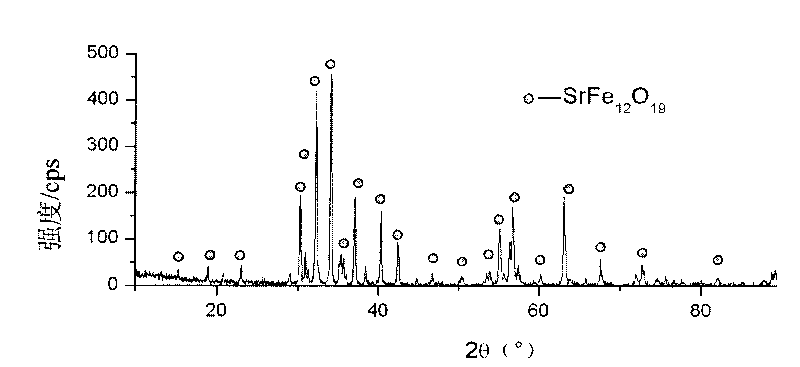

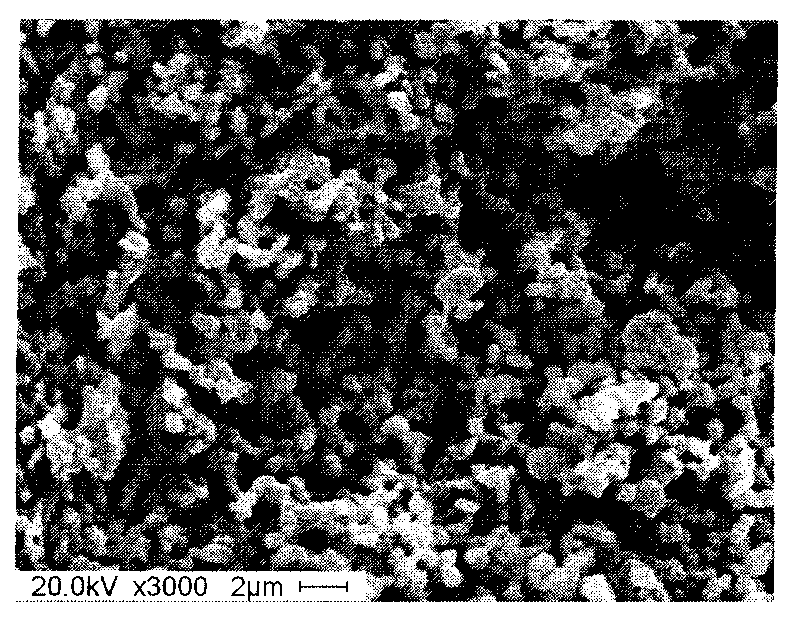

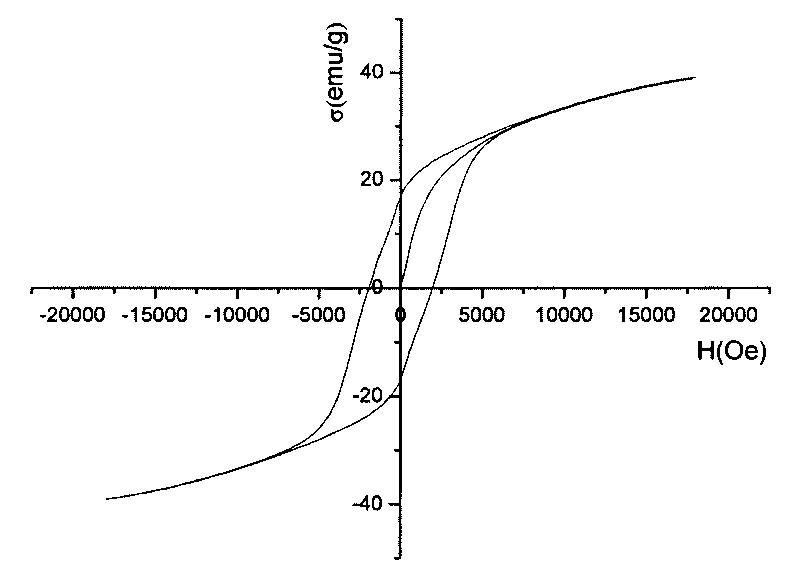

[0033] Taking strontium ferrite pre-sintered material as an example, a synthesis method of hard ferrite pre-sintered material.

[0034] (1), according to the molar ratio of 5.8:1:0.01 Fe is calculated 2 o 3 , SrCO 3 and Nd 2 o 3 proportioning, and then weighed;

[0035] (2), put the weighed material into the ball mill tank for mixing with water, material and ball mass ratio of 1:2:2, the ball milling speed is 200r / min, and the ball milling is 2h;

[0036] (3), the ball mill slurry was left to settle and poured out the water and dried in an electric oven for 20 hours;

[0037] (4), the dried material is put into an alumina crucible;

[0038] (5) Put the alumina crucible containing the material into a microwave oven, heat it with a microwave physical field with a frequency of 2450MHz, raise the temperature to 1215°C at a heating rate of 50°C / min, and then keep it warm for 60min, the particle size can be obtained. 0.8μm single-phase ferrite pre-fired material;

[0039] (6...

Embodiment 2

[0044] Taking barium ferrite pre-sintered material as an example, a synthesis method of hard ferrite pre-sintered material.

[0045] (1), according to the molar ratio of 5.6:1:0.02 Fe is calculated 2 o 3 、BaCO 3 and La 2 o 3 proportioning, and then weighed;

[0046] (2), put the weighed material into the ball mill tank for mixing with water, material and ball mass ratio of 1:2:2, the ball milling speed is 200r / min, and the ball milling is 2h;

[0047] (3), the ball mill slurry was left to settle and poured out the water and dried in an electric oven for 20 hours;

[0048] (4), the dried material is put into an alumina crucible;

[0049] (5) Put the alumina crucible containing the material into a microwave oven, heat it with a microwave physical field with a frequency of 3000MHz, raise the temperature to 1150°C at a heating rate of 70°C / min, and then keep it warm for 80min, the particle size can be obtained. 0.9μm single-phase ferrite pre-fired material;

[0050] (6), a...

Embodiment 3

[0052] Taking lead ferrite pre-sintered material as an example, a synthesis method of hard ferrite pre-sintered material.

[0053](1), according to the molar ratio of 1:5.8:0.025 to calculate Fe 2 o 3 , PbCO 3 And the proportioning of CaO, weigh then;

[0054] (2), put the weighed material into the ball mill tank for mixing with water, material and ball mass ratio of 1:2:2, the ball milling speed is 200r / min, and the ball milling is 2h;

[0055] (3), the ball mill slurry was left to settle and poured out the water and dried in an electric oven for 2 hours;

[0056] (4), the dried material is put into an alumina crucible;

[0057] (5) Put the alumina crucible containing the material into a microwave oven, heat it with a microwave physical field with a frequency of 300MHz, and heat it up to 1300°C at a heating rate of 30°C / min, and then keep it for 60min to obtain a particle size of about 1.5μm single-phase ferrite pre-fired material;

[0058] (6), after the synthesized ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com