Method for preparing nitrogen-carbon co-coated lithium titanate anode material

A negative electrode material and a technology for coating lithium titanate, which is applied in the field of preparing carbon-nitrogen co-coated lithium titanate negative electrode materials, can solve problems such as poor electronic conductivity, and achieve high rate performance, good cycle performance, and uniform grain distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1L

[0023] Example 1Li 4 Ti 5 O 12 Preparation of negative electrode materials

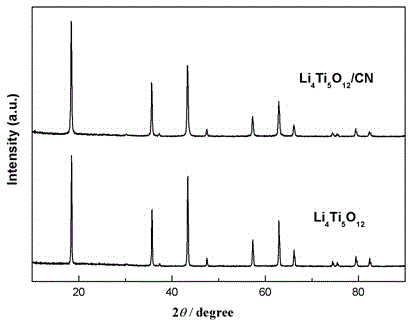

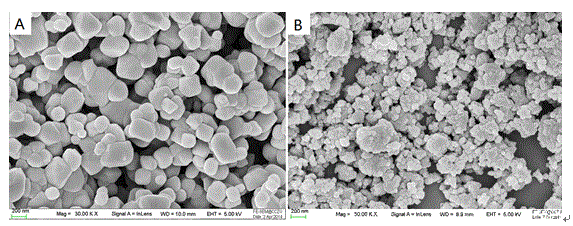

[0024] Weigh 0.06mol of lithium carbonate and 0.075mol of titanium dioxide into a 250ml zirconia ball mill jar; add 35ml of acetone and zirconia beads with a diameter of 3mm; ball mill and mix for 6 hours at 500 rpm to obtain a slurry, then vacuum dry at 100°C A lithium titanate precursor was obtained; the lithium titanate precursor was heat-treated at 750° C. for 8 hours in an argon atmosphere. The target lithium titanate negative electrode material was obtained; wherein, the heat treatment was calcined at 750° C. for 8 hours. X-ray diffraction pattern see figure 1 , scanning electron microscope image see figure 2 .

Embodiment 2L

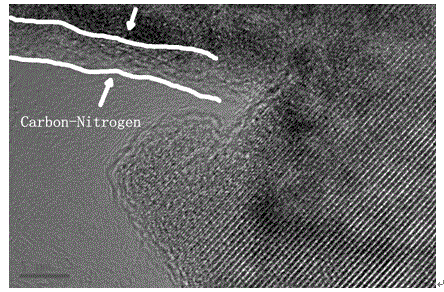

[0025] Example 2Li 4 Ti 5 O 12 / CN composite anode material preparation

[0026] Weigh 0.06mol of lithium carbonate and 0.075mol of titanium dioxide and 2g of melamine-formaldehyde resin into a 250ml zirconia ball mill jar; add 35ml of acetone and zirconia beads with a diameter of 3mm; ball mill and mix for 6 hours at 500 rpm to obtain the slurry The lithium titanate / carbon nitrogen composite precursor was obtained by vacuum drying at 100°C; the lithium titanate / carbon nitrogen composite precursor was heat-treated at 750°C for 8 hours in an argon atmosphere to obtain the target product carbon-nitrogen co-coated titanic acid Lithium negative electrode material; wherein, the heat treatment is calcined at 750° C. for 8 hours. X-ray diffraction pattern see figure 1 , scanning electron microscope image see figure 2 .

[0027] Depend on figure 1 It can be seen that the diffraction peaks of the samples obtained in Example 1 and Example 2 are consistent with those...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com