Preparation method of oriented ZeTe nanocrystals

A nanocrystal and crystal technology, which is applied in the field of preparation of oriented nanocrystal ZnTe crystals, can solve the problems of decreased optical performance, increased process cost, high temperature, etc., and achieves the effects of low preparation cost, simple and efficient preparation method, and uniform grain distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

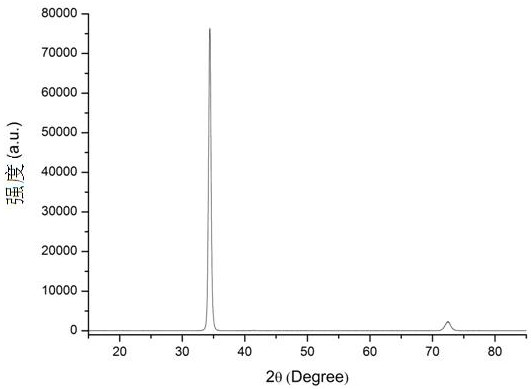

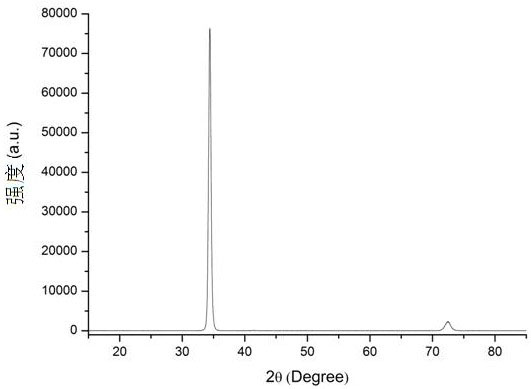

Image

Examples

Embodiment 1

[0036] The preparation process of a orientation nanocrystalline ZnTe crystal of the present invention comprises the following steps:

[0037] (1) Use metal Zn and Te with a purity higher than 99.999% as raw materials, mix according to the atomic ratio of 1:1, and use high-energy planetary ball milling equipment to uniformly mix the raw materials. The mixing time is 4 hours, and the mixed The raw material is placed in a vacuum of 10 -3 In the vacuum melting furnace of Pa, the melting furnace is heated to 1200°C for melting, and after the melting is completed, it is refined for 20 minutes and then cast to obtain the ZnTe alloy material;

[0038] (2), casting the ZnTe alloy material obtained in step (1) into a columnar mold with an inner diameter of 20 mm, and cooling to room temperature with the furnace to form a ZnTe alloy rod;

[0039] (3) Process the ZnTe alloy rod obtained in step (2) into a diameter of 20 mm and a height of 10 mm to form a ZnTe alloy target;

[0040] (4)...

Embodiment 2

[0049] The preparation process of a orientation nanocrystalline ZnTe crystal of the present invention comprises the following steps:

[0050] (1) Use metal Zn and Te with a purity higher than 99.999% as raw materials, mix according to the atomic ratio of 1:1, and use high-energy planetary ball milling equipment to uniformly mix the raw materials. The mixing time is 4 hours, and the mixed The raw material is placed in a vacuum of 10 -3 In the vacuum melting furnace of Pa, the melting furnace is heated to 1200°C for smelting, after the smelting is completed, it is refined for 20 minutes and then cast to obtain the ZnTe alloy material;

[0051] (2), casting the ZnTe alloy material obtained in step (1) into a columnar mold with an inner diameter of 20 mm, and cooling to room temperature with the furnace to form a ZnTe alloy rod;

[0052] (3) Process the ZnTe alloy rod obtained in step (2) into a diameter of 20 mm and a height of 10 mm to form a ZnTe alloy target;

[0053] (4) U...

Embodiment 3

[0062] The preparation process of a orientation nanocrystalline ZnTe crystal of the present invention comprises the following steps:

[0063] (1) Use metal Zn and Te with a purity higher than 99.999% as raw materials, mix according to the atomic ratio of 1:1, and use high-energy planetary ball milling equipment to uniformly mix the raw materials. The mixing time is 4 hours, and the mixed The raw material is placed in a vacuum of 10 -3 In the vacuum melting furnace of Pa, the melting furnace is heated to 1200°C for melting, and after the melting is completed, it is refined for 20 minutes and then cast to obtain the ZnTe alloy material;

[0064] (2), casting the ZnTe alloy material obtained in step (1) into a columnar mold with an inner diameter of 20 mm, and cooling to room temperature with the furnace to form a ZnTe alloy rod;

[0065] (3) Process the ZnTe alloy rod obtained in step (2) into a diameter of 20 mm and a height of 10 mm to form a ZnTe alloy target;

[0066] (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com