Laser synthesis method of LaGaO3 based solid electrolyte

A solid electrolyte, lanthanum gallate-based technology, which is applied in the field of laser synthesis for preparing lanthanum gallate-based solid electrolytes, can solve the problems of high preparation cost, difficulty, difficulty in sintering and densification, etc., and achieves simple reaction process, large-scale, The effect of excellent electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

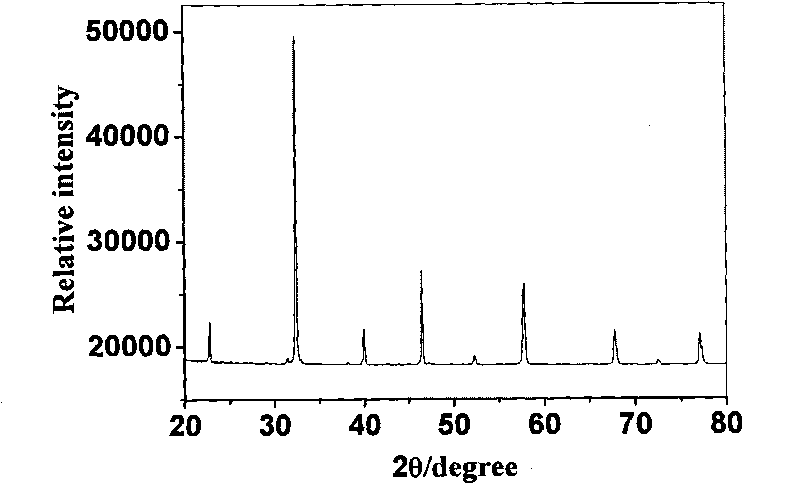

[0026] Example 1: The laser wavelength is fixed at 10.6 μm, the beam scanning speed is 1 mm / s, and the power density is 1.0 kW / cm 2 La 0.9 Sr 0.1 Ga 0.8 Mg 0.2 o 3-δ (x=0.1, y=0.2) solid electrolyte:

[0027] La before weighing 2 o 3 , Ga 2 o 3 and MgO in a furnace at 1000°C for 7 hours to decompose carbonates and hydroxides, and dry the rest of the raw materials in a drying oven for 2 hours, and then the raw materials that can generate lanthanum gallate electrolytes are prepared according to La 2 o 3 , SrCO 3 , Ga 2 o 3 , MgO molar ratio 9: 2: 8: 4, ground in an agate mortar for 1 h, dried the sample in a drying oven for 2 h, and pressed it into strips with a hydraulic press. The size of the strips is 40 mm long, 5 mm wide, and thick 5mm, put the pressed strip into a weighing bottle and cover it to avoid water absorption and pulverization, and finally sinter it with a laser. During the sintering process, the laser wavelength is fixed at 10.6μm, the beam scanning...

Embodiment 2

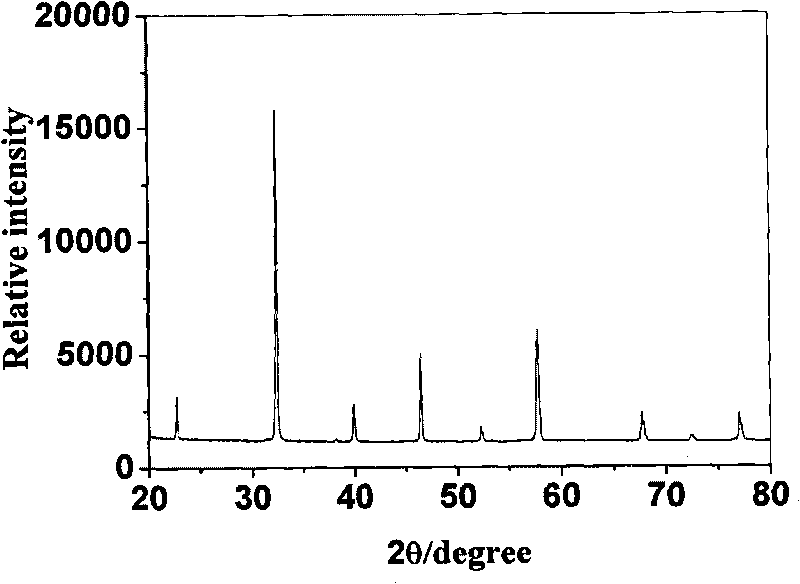

[0028] Embodiment 2: The difference from Embodiment 1 is that the power density is 1.1kW / cm 2 , forming La 0.9 Sr 0.1 Ga 0.8 Mg 0.2 o 3-δ For the corresponding X-ray diffraction phase analysis see figure 2 , figure 2 The XRD results showed the formation of pure La 0.9 Sr 0.1 Ga 0.8 Mg 0.2 o 3-δ Mutually. Using a scanning electron microscope to observe La 0.9 Sr 0.1 Ga 0.8 Mg 0.2 o 3-δ The microstructure of the product La 0.9 Sr 0.1 Ga 0.8 Mg 0.2 o 3-δ The SEM picture is as follows Figure 15 As shown, it can be seen that the prepared La 0.9 Sr 0.1 Ga 0.8 Mg 0.2 o 3-δ It has a regular structure, dense organization, and the grain size is about 5-10 μm; the conductivity of the product is tested by the method of AC impedance spectroscopy with a conductivity tester, and the product La 0.9 Sr 0.1 Ga 0.8 Mg 0.2 o 3-δ The conductivity varies with temperature see Figure 16 , it can be seen that the conductivity reaches 0.134S / cm at 800°C.

Embodiment 3

[0029] Embodiment 3: The difference from Embodiment 1 is that the power density is 1.2kW / cm 2 , forming La 0.9 Sr 0.1 Ga 0.8 Mg 0.2 o 3-δ For the corresponding X-ray diffraction phase analysis see image 3 , image 3 The XRD results showed the formation of pure La 0.9 Sr 0.1 Ga 0.8 Mg 0.2 o 3-δ Mutually.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com