Method for manufacturing alligatoring ring matrix with novel structure

A manufacturing method and new structure technology, applied to gears, other household appliances, household appliances, etc., can solve the problems of high manufacturing cost, insufficient strength of large-diameter gear rings, low material utilization rate, etc., and achieve the effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

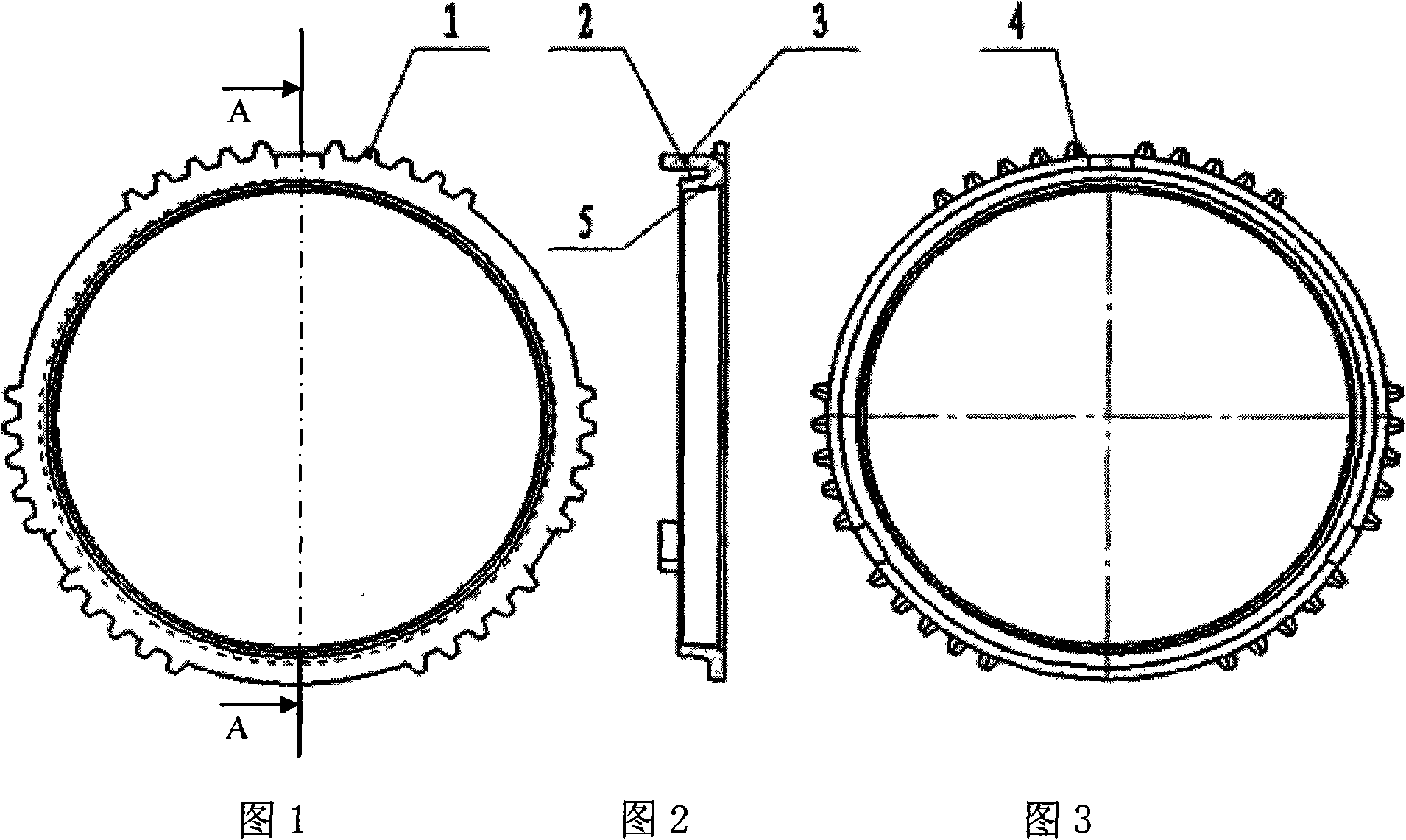

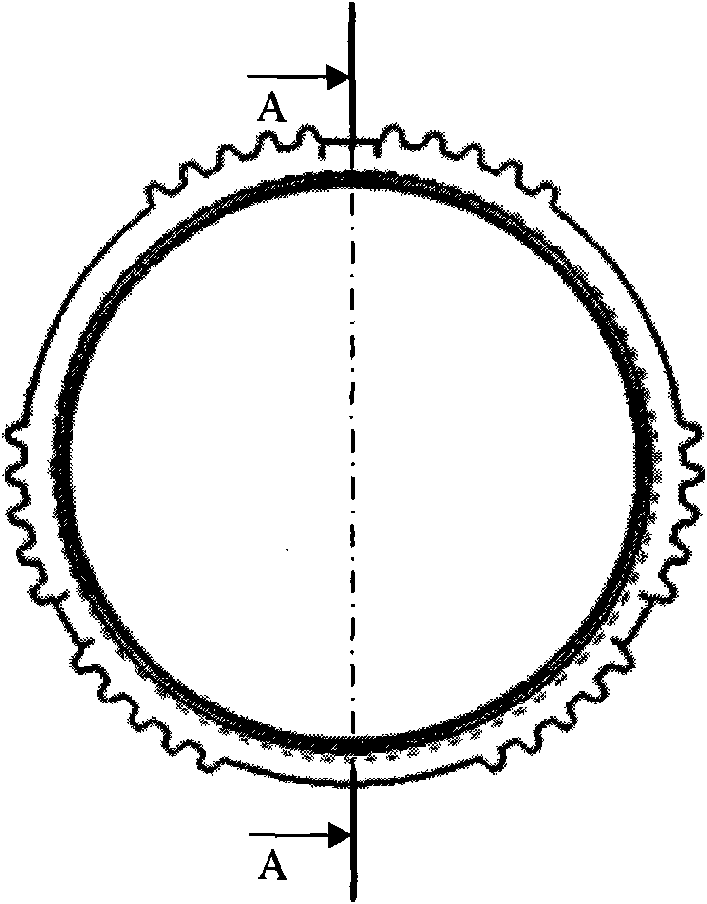

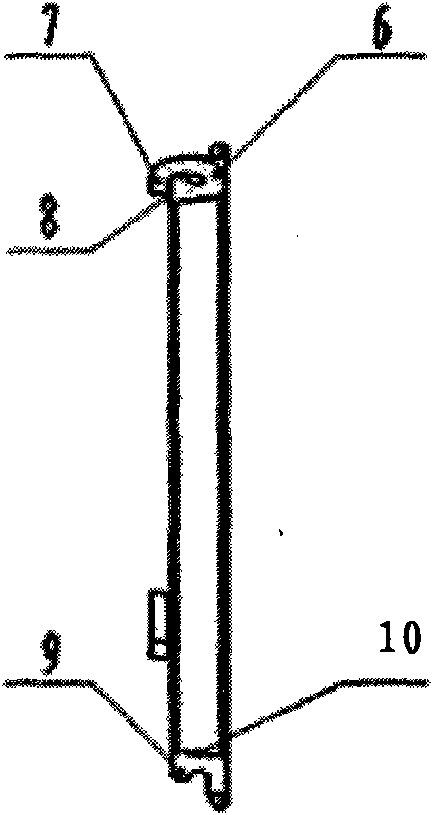

[0067] Made as figure 1 , figure 2 , image 3 The schematic diagram of the processing process of the gear ring base shown in the figure is as follows: Figure 33 , the specific process steps refer to Figure 7-Figure 20 :

[0068] Process 1: punching and blanking.

[0069] Equipment: full hydraulic fine blanking press

[0070] Mold working drawing see Figure 7 , use the outer slider of the special press to drive the ring gear blank holder 12 to move down, press the material on the upper end surface of the die, and at the same time, the inner slide of the full hydraulic fine blanking press moves down quickly to drive the punch 11 of the mold to move down. The outer contour of the product is cut, and at the same time, the inner punch of the full hydraulic fine blanking press moves up quickly, driving the inner punch 17 upward, and under the action of the inner hole of the punch 11, the inner contour of the product is cut.

[0071] After the blanking is completed, the up...

Embodiment 2

[0107] Made as Figure 4 , Figure 5 , Figure 6 The gear ring base with the upper flange is shown, and the schematic diagram of its processing process is as follows Figure 34 , the specific process steps refer to Figure 21-Figure 32 :

[0108] Process 1: punching and blanking.

[0109] Equipment: full hydraulic fine blanking press

[0110] Mold working drawing see Figure 21, using the outer slider of the special press to drive the ring gear blank holder 55 to move down to press the material on the upper end surface of the die, and at the same time, the inner slide of the full hydraulic fine blanking press moves down quickly to drive the punch 56 of the mold to move down. The outer contour of the product is cut, and at the same time, the inner punch of the full hydraulic fine blanking press moves up quickly, driving the inner punch 59 upward, and under the action of the inner hole of the punch 56, the inner contour of the product is cut.

[0111] After the blanking i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com