Method for preparing nano lithium titanate by template method

A nano-lithium titanate, template method technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing and other directions, can solve the problems of hidden battery, high cost, low voltage, etc., to save production costs, accurate lithium-titanium ratio, use good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

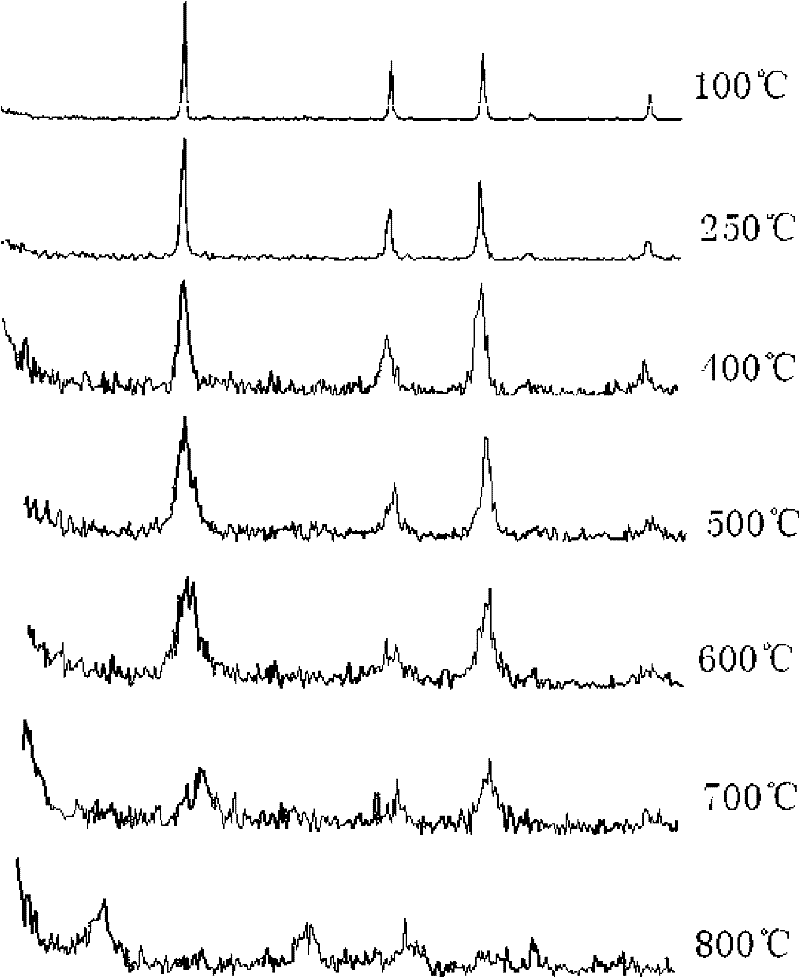

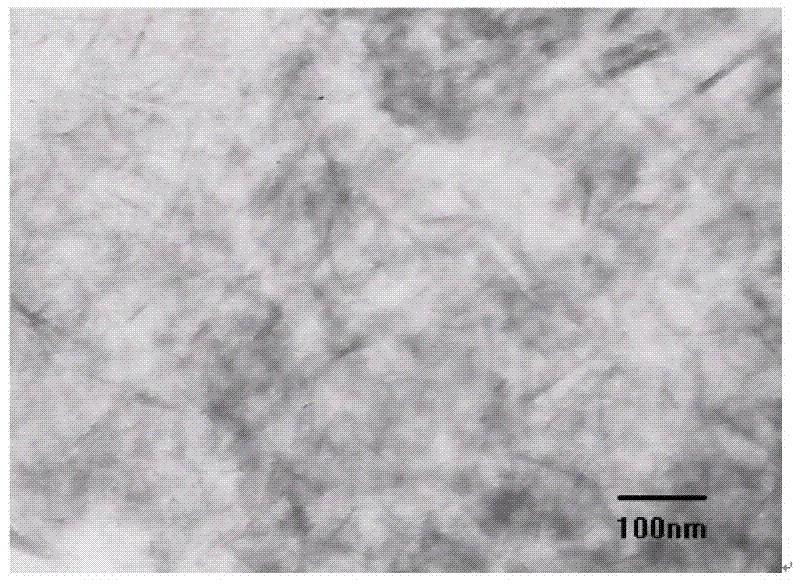

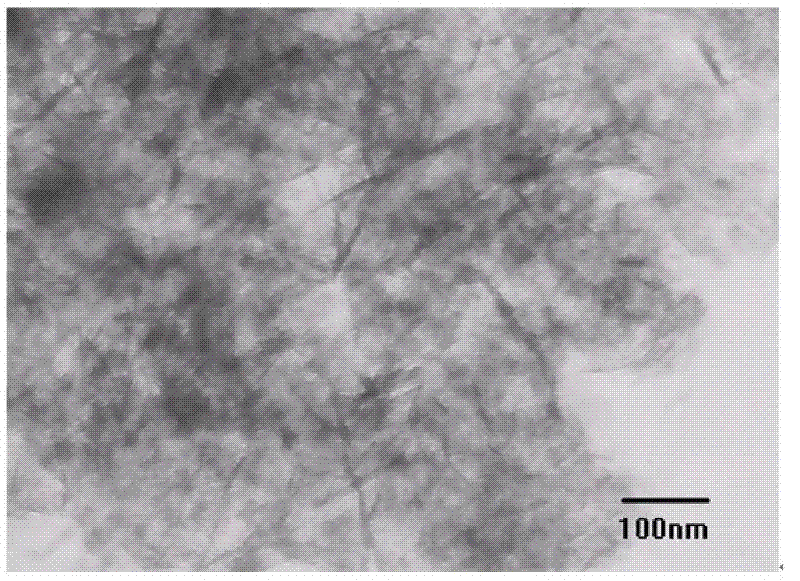

[0033] Embodiment 1 of the present invention: the method for preparing nano-lithium titanate by template method, 1 part of titanium tetrachloride is added to the water of normal temperature, and industrial titanium salt is completely hydrolyzed to obtain transparent aqueous solution containing titanium oxychloride and hydrochloric acid; Add 4 parts of sodium hydroxide to the aqueous solution for neutralization reaction to obtain metatitanic acid precipitation; wash with distilled water to remove chloride ions contained in the metatitanic acid precipitation to obtain gel metatitanic acid; to gel metatitanic acid Add 0.8 parts of lithium hydroxide and 2 parts of methyl cellulose with a degree of substitution of 2.6 to titanic acid and mix to obtain the precursor; dry and dehydrate the precursor at 100°C for 12 hours to obtain nano-titanium dioxide, lithium hydroxide and methyl cellulose A mixture of elements; adding ethanol (methanol can also be used) to the mixture to dissolve a...

Embodiment 2

[0034] Embodiment 2 of the present invention: the method for preparing nano-lithium titanate by template method, 1 part of titanyl sulfate is added to water at normal temperature, and titanyl sulfate is completely dissolved to obtain a transparent aqueous solution; 4 parts of sodium hydroxide are added to the aqueous solution Perform a neutralization reaction to obtain a metatitanic acid precipitate; wash with distilled water to remove sulfate ions contained in the metatitanic acid precipitate to obtain a gel-like metatitanic acid; add 0.8 parts of hydroxide to the gel-like metatitanic acid Lithium and 4 parts of tartaric acid were mixed to obtain a precursor; the precursor was dried and dehydrated at 90°C for 16 hours to obtain a mixture of nano-titanium dioxide, lithium hydroxide and tartaric acid; ethanol was added to the mixture to dissolve and recover tartaric acid to obtain A mixture F of nano-titanium dioxide and lithium hydroxide as a secondary template; calcining F at ...

Embodiment 3

[0035]Embodiment 3 of the present invention: a method for preparing nano-lithium titanate by template method, adding 1 part of titanium sulfate to water at normal temperature, heating to 80° C., to completely hydrolyze titanium sulfate to obtain a transparent aqueous solution of titanyl sulfate; Add 4 parts of sodium hydroxide to neutralization reaction to obtain metatitanic acid precipitation; wash with distilled water to remove sulfate ions contained in the metatitanic acid precipitation to obtain gel-like metatitanic acid; to gel-like metatitanic acid Add 0.8 parts of lithium hydroxide and 4 parts of dimethyl terephthalate to the acid and mix to obtain the precursor; dry and dehydrate the precursor at 90°C for 16 hours to obtain nano-titanium dioxide, lithium hydroxide and dimethyl terephthalate A mixture of methyl esters; adding toluene to the mixture to dissolve dimethyl terephthalate and reclaim it to obtain a mixture F of nano-titanium dioxide and lithium hydroxide as a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com