Microparticle counting system using laser imaging and projection

A technology of tiny particles and laser imaging, applied in the field of counting system, it can solve the problems of projection distortion, voltage instability, reduce calculation, etc., to achieve the effect of reliable data science, avoid errors, accurate counting and particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

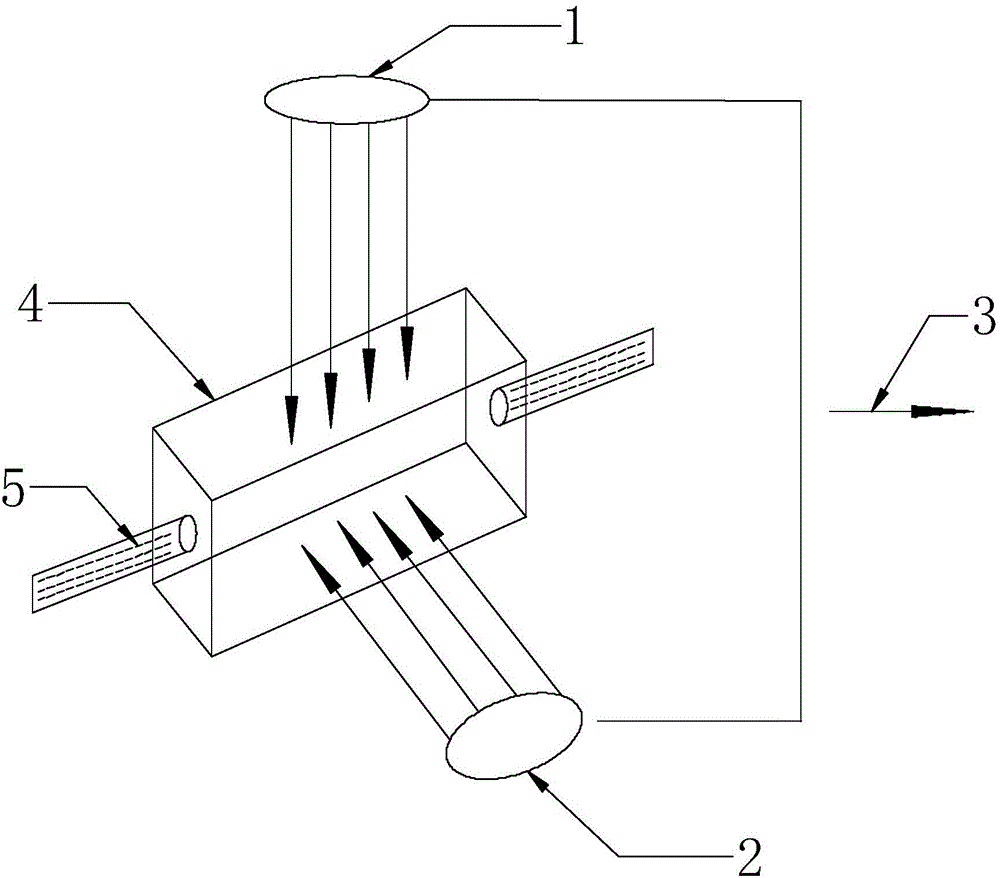

[0009] The embodiment of the present invention uses laser imaging and projection micro particle counting system, including a first laser source 1 irradiated along the X-axis direction and a second laser source 2 irradiated along the Y-axis direction, the first laser source 1 and the second laser The source 2 is respectively connected with the circuit board and the chip 3 in the counting device, and also includes a regular channel 4 along the Z-axis direction. A tiny particle medium 5 is arranged in the regular channel 4. The speed of the measured medium is within a certain range. The laser test head The fixed or laser test head moves at the same speed as the measured medium, is relatively stationary, and keeps the same speed. The current reflected on the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com