Method for preparing binder resin for water-based ink and application thereof

A technology of water-based inks and binders, applied in inks, applications, household appliances, etc., can solve the problems of organic solvent volatilization pollution, poor ink use effect, and environmental hazards, and achieve good stability, excellent adhesion fastness, good The effect of wetting properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The embodiment of the present invention provides a preparation method and application of a binder resin for water-based ink, which specifically includes the following steps: mixing 40-70 parts by mass of polyester and / or polyether polyol with 1-10 parts by mass of ionizing agent Mix and heat to 100-110°C, cool to 50-60°C, add 10-30 parts by mass of diisocyanate, heat up to 70-80°C and react for 3-4 hours to prepare a preprepared product with an NCO content of 4%-5% (mass). Polymer;

[0021] Dissolving 1 to 10 parts by mass of a linking agent in 40 to 70 parts by mass of cold water at 5 to 10°C is added to 10 to 30 parts by mass of the prepolymer under stirring to obtain a polyurethane emulsion;

[0022] Stir and mix 30-60 parts by mass of the prepared polyurethane emulsion, 1-5 parts by mass of ammonia water with a concentration of 28%, 20-40 parts by mass of deionized water and 1-5 parts by mass of thickener , to obtain an aqueous emulsion with a solid content of 20% ...

Embodiment 1

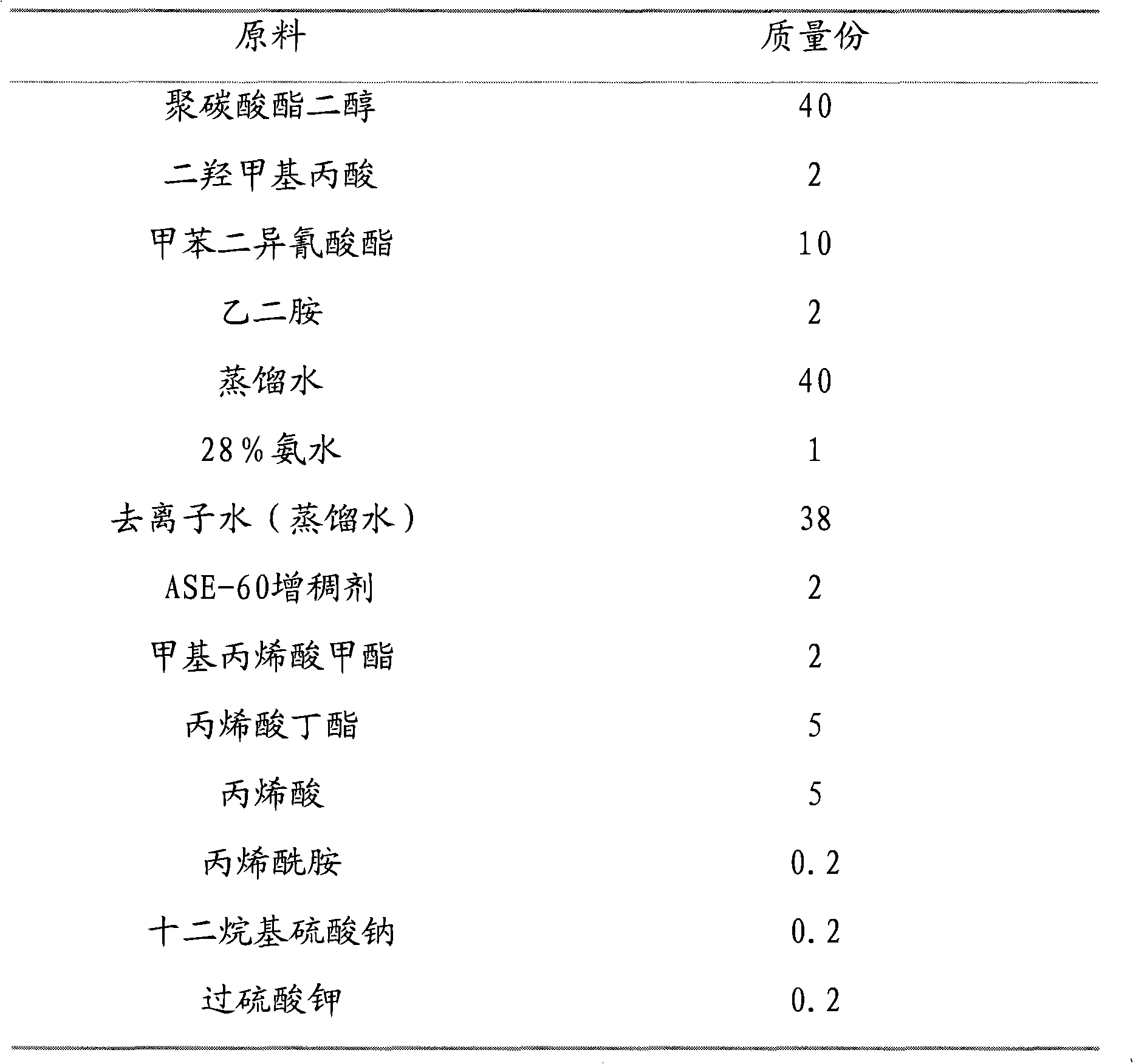

[0031] First, take the raw materials according to the ratio in the table below:

[0032]

[0033] The preparation method is as follows:

[0034] (1) Mix and heat 40 parts by mass of polyester / polyether polyol and 2 parts by mass of ionizing agent dimethylolpropionic acid, add 10 parts by mass of diisocyanate after cooling, and heat up to 70-80°C for 3- Prepared into a prepolymer with an NCO content of 4% to 5% (mass) in 4 hours;

[0035] (2) Dissolve 2 parts by mass of the extender ethylenediamine in 40 parts by mass of cold water, and add it to 52 parts by mass of the prepolymer obtained above under the stirring condition of a turbo mixer, and fully hydrate to obtain a polyurethane emulsion ;

[0036] (3) Stir and mix the 94 mass parts of polyurethane emulsion obtained with 28% ammonia water of 1 mass part, the deionized water of 38 mass parts, and the ASE-60 thickener of 2 mass parts to obtain an aqueous emulsion;

[0037] (4) 2 parts by mass of methyl methacrylate, 5 ...

Embodiment 2

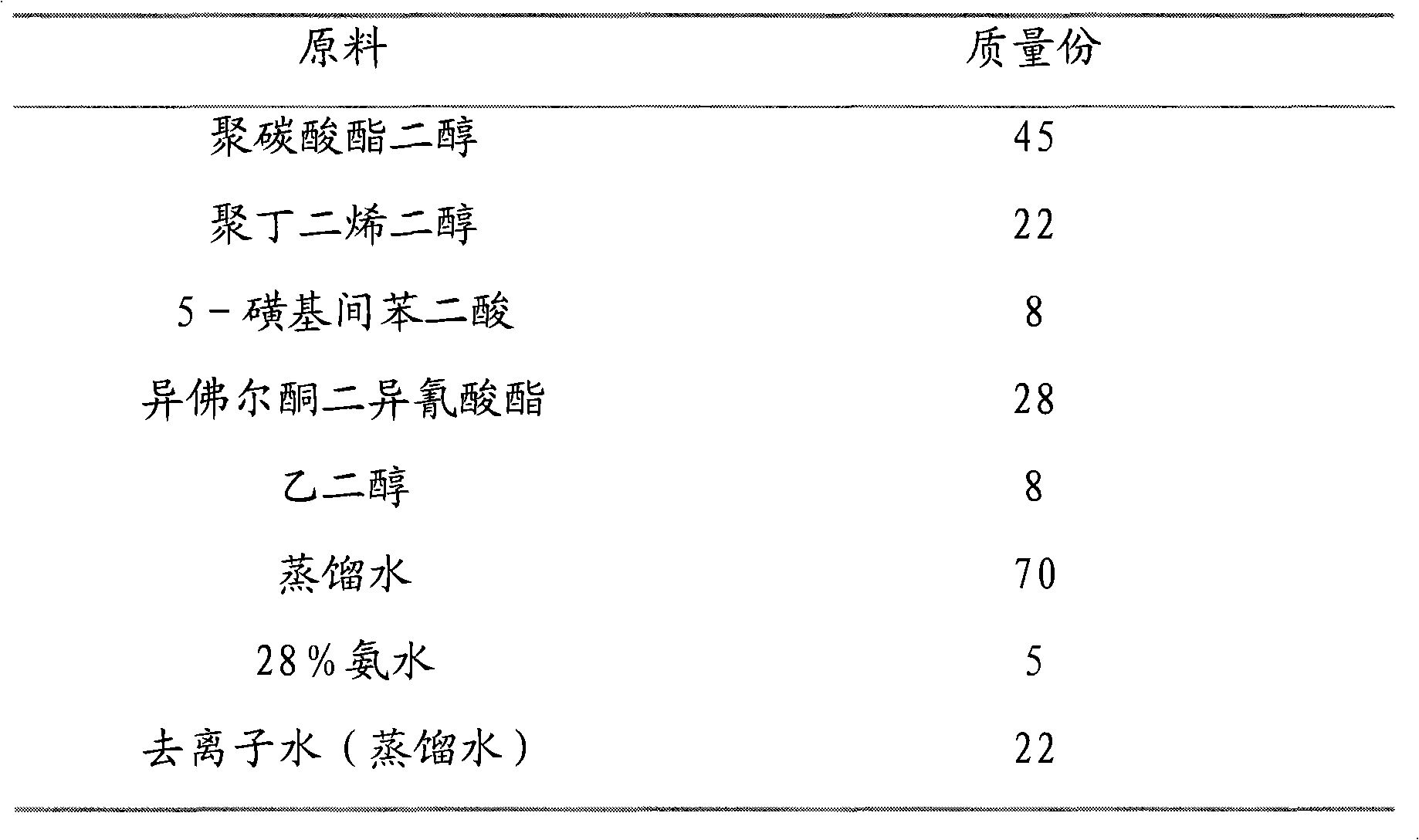

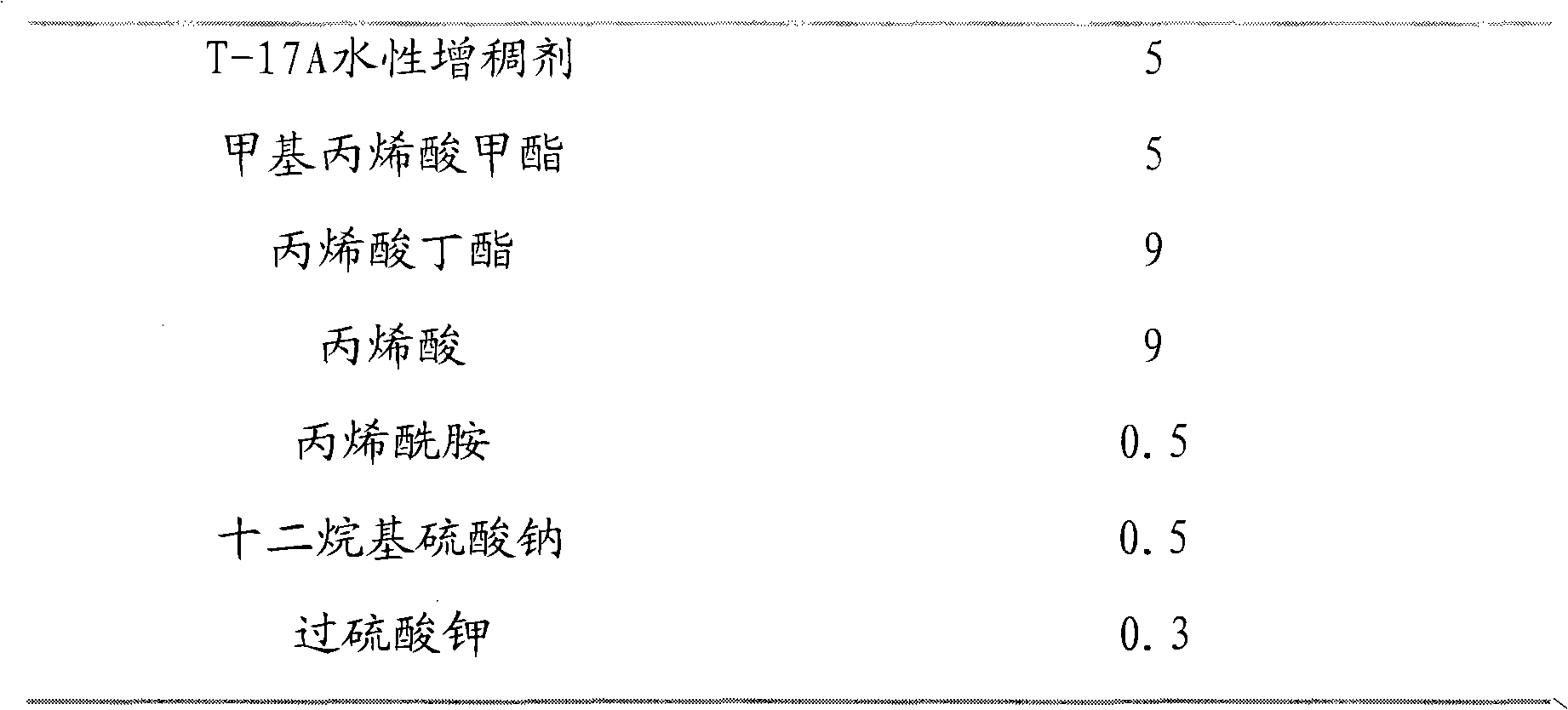

[0039] Present embodiment provides a kind of method that adopts another kind of proportioning raw material to prepare the resin that water-based ink is used, and gets each raw material according to the following table proportioning:

[0040]

[0041]

[0042] The preparation method is as follows:

[0043] (1) Mix 45 parts by mass of polycarbonate diol and 22 parts by mass of polybutadiene diol with 2 parts by mass of ionizing agent 5-sulfoisophthalic acid and heat to 100-110°C until dissolved and mixed After fully cooling to 50-60°C, add 28 parts by mass of isophorone diisocyanate, heat up to 70-80°C and react for 3-4 hours to prepare a prepolymer with an NCO content of 4%-5% (by mass);

[0044] (2) Dissolve 8 parts by mass of ethylene glycol as a linking agent in 70 parts by mass of cold water at 5-10°C, and add to 97 parts by mass of the above-obtained prepolymer under the stirring condition of a turbo mixer, and hydrate Fully obtain polyurethane emulsion;

[0045] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freshness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com