Anti-oxidation composite membrane electrode

A composite film, anti-oxidation technology, applied in circuits, discharge tubes, electrical components, etc., can solve problems such as reducing the display quality of the display screen, and achieve the effect of improving the display quality, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

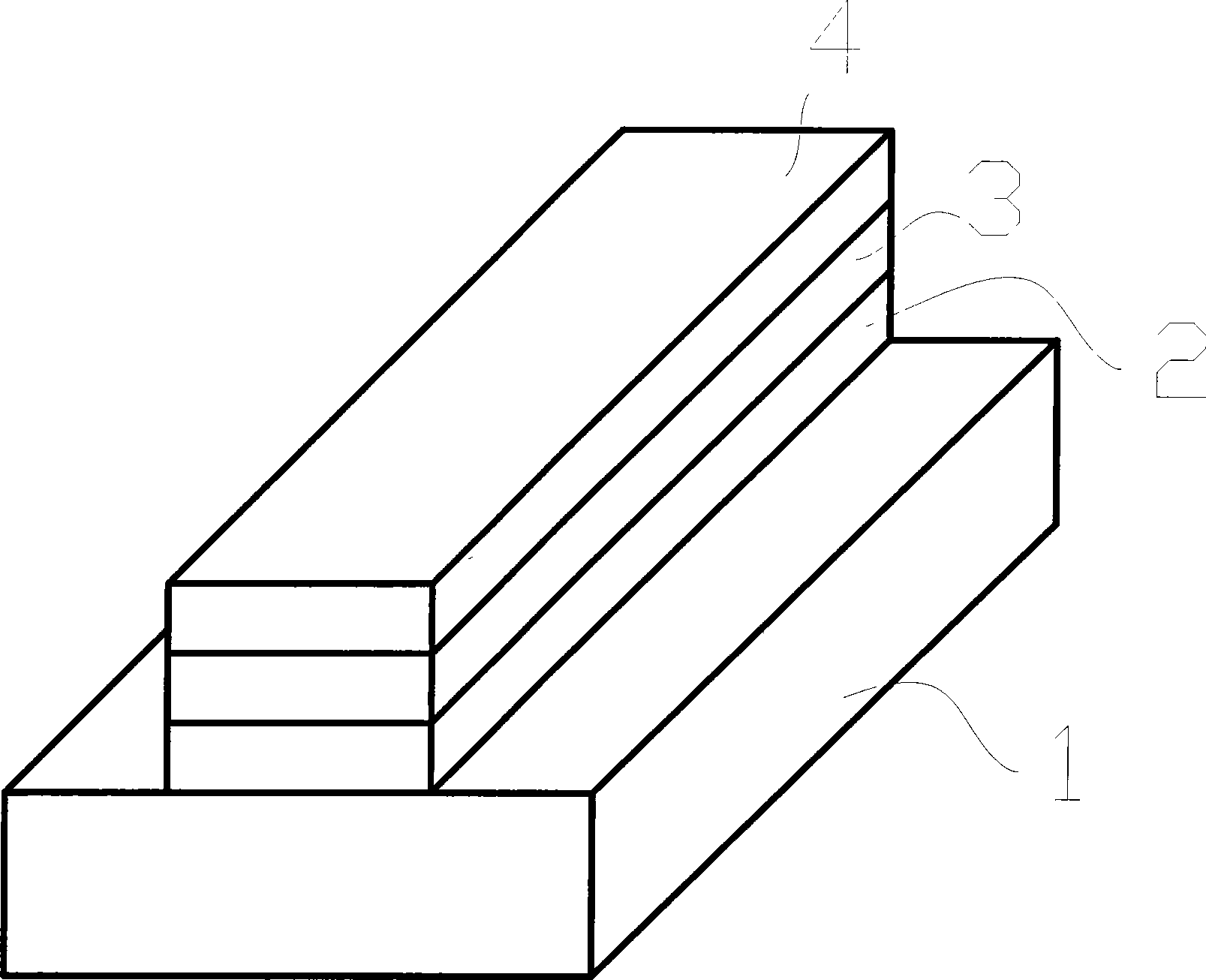

[0015] Such as figure 1 As shown, the anti-oxidation composite thin film electrode of the present invention includes a substrate 1 on which a transition layer 2 , a conductive layer 3 and a protective layer 4 are sequentially arranged.

[0016] The above-mentioned substrate is an insulating material with a smooth surface, which can be an inorganic glass substrate, an organic polymer substrate, a ceramic substrate or a composite substrate composed of these materials.

[0017] The aforementioned transition layer is made of metal or compound. The metal material forming the transition layer is one of chromium, aluminum, titanium, molybdenum, nickel, copper or an alloy or mixture containing these metal materials. The material of the compound forming the transition layer is a laminated structure composed of one or more of indium oxide, zinc oxide, nickel oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com