Anti-scratch aqueous polyurethane disperse system with high hygrometric state adhesive force and use thereof

A technology of wet adhesion and water-based polyurethane, applied in the field of coatings, can solve problems such as failure to use, low glass transition temperature of polyether chain segments, long curing time at room temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

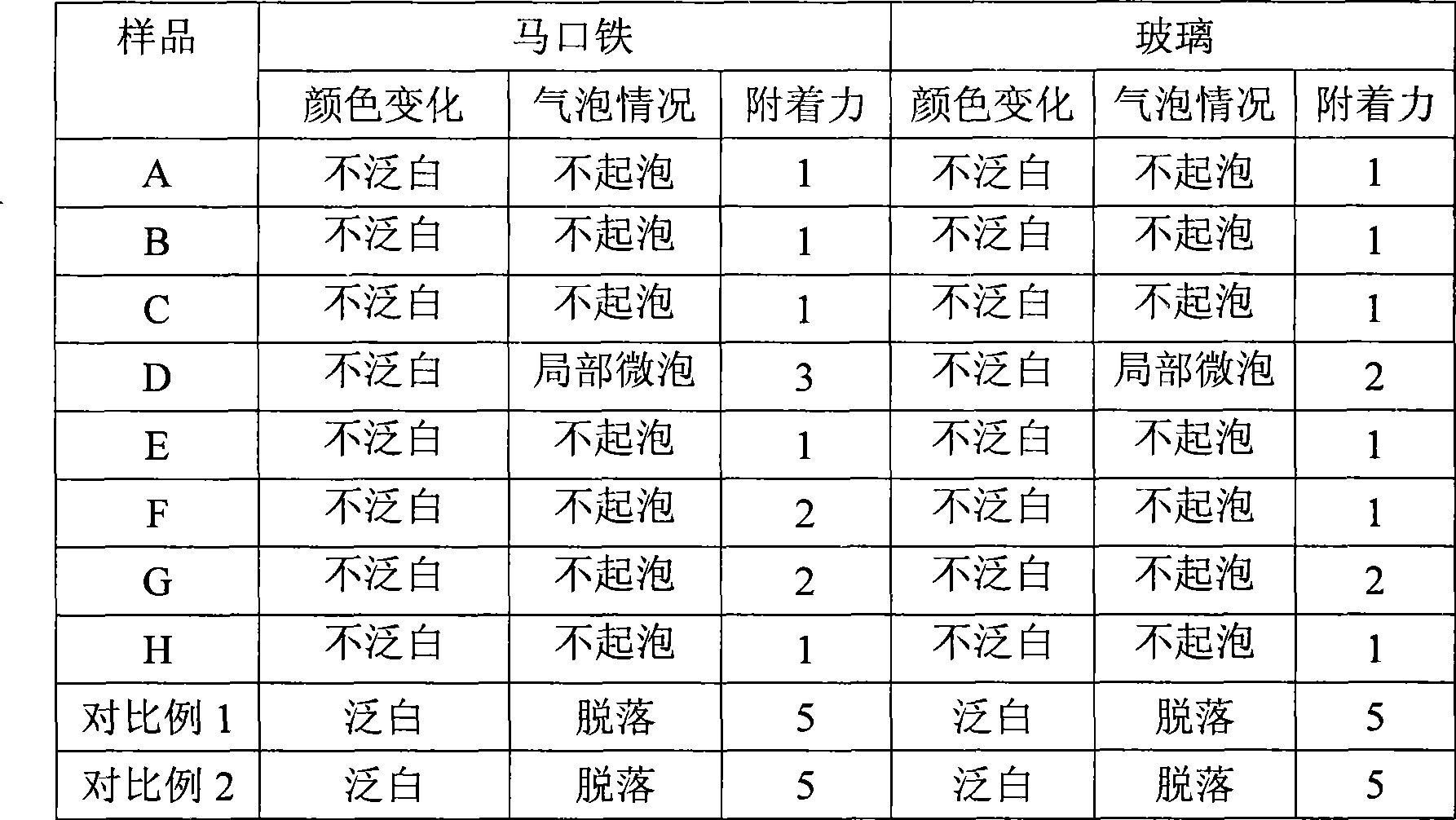

Examples

Embodiment 1

[0107] Embodiment 1 Aqueous polyurethane dispersion 1

[0108] Mix 100.0g polyester polyol II (molecular weight 1000), 8.0g dimethylol propionic acid and 18.0g N-methylpyrrolidone and heat to 70°C, stir until the dimethylol propionic acid is completely dissolved; add 21.0g toluene di Isocyanate, react at 70°C for 30 minutes, then add 30.2g of hexamethylene diisocyanate, heat up to 100°C for reaction until the -NCO content reaches 6.4%, cool down to 60°C, add 6.0g of triethylamine to neutralize the prepolymer; add 156.0g of water, stir vigorously to disperse the polyurethane prepolymer, at the same time slowly add 7.9g of ethylenediamine and 1.74g of D-15 coupling agent mixture, and then stir for 30min until the FTIR spectrum no longer shows —NCO group group absorption peak. An aqueous polyurethane dispersion with a solid content of 50% was obtained.

Embodiment 2

[0109] Embodiment 2 Waterborne polyurethane dispersion 2

[0110] Mix 80.0g polyester polyol I (molecular weight 2000), 20.0g PTMEG (molecular weight 1000), 7.7g dimethylol propionic acid and 16.5g N-methylpyrrolidone, mix and heat to 80°C, stir until the dimethylol propionic acid is completely Dissolve; add 10.5g diphenylmethane diisocyanate, react at 70°C for 30 minutes, then add 37.3g isophorone diisocyanate, heat up to 100°C and react until the -NCO group content reaches 5.0%, cool down to 60°C, add 8.2g triisopropylamine to neutralize the prepolymer; then add 410.0g water, stir vigorously to disperse the polyurethane prepolymer, at the same time slowly add 2.3g ethylenediamine and 17.1g D-17 coupling agent mixture, after adding Stir for 30 min until the -NCO group absorption peak no longer appears in the FTIR spectrum. An aqueous polyurethane dispersion with a solid content of 30% was obtained.

Embodiment 3

[0111] Embodiment 3 aqueous polyurethane dispersion 3

[0112] Mix 100.0g of polyester polyol V (molecular weight 1000), 13.4g of dimethylol propionic acid and 36.4g of N-methylpyrrolidone and heat to 70°C, stir until the dimethylol propionic acid is completely dissolved; add 5.0g of hexadiene Isocyanate, 14.0g hexamethylene diisocyanate trimer and 65.0g isophorone diisocyanate, heat up to 100°C to react until the -NCO content reaches 5.8%, cool down to 60°C, add 10.1g triethylamine to neutralize the prepolymer Add 785g of water again, stir vigorously to disperse the polyurethane prepolymer, and stir until the FTIR spectrum no longer shows the —NCO group absorption peak. An aqueous polyurethane dispersion with a solid content of 20% was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com