Method for simultaneously monitoring photolithography exposure condition and registration photoetching precision

A technology of exposure conditions and overlay accuracy, applied in the field of online monitoring of lithography process, can solve the problems of inability to measure, high cost of implementation, high cost of measurement, etc., and achieve the effect of improving online monitoring ability, reducing production cost, and simplifying measurement steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

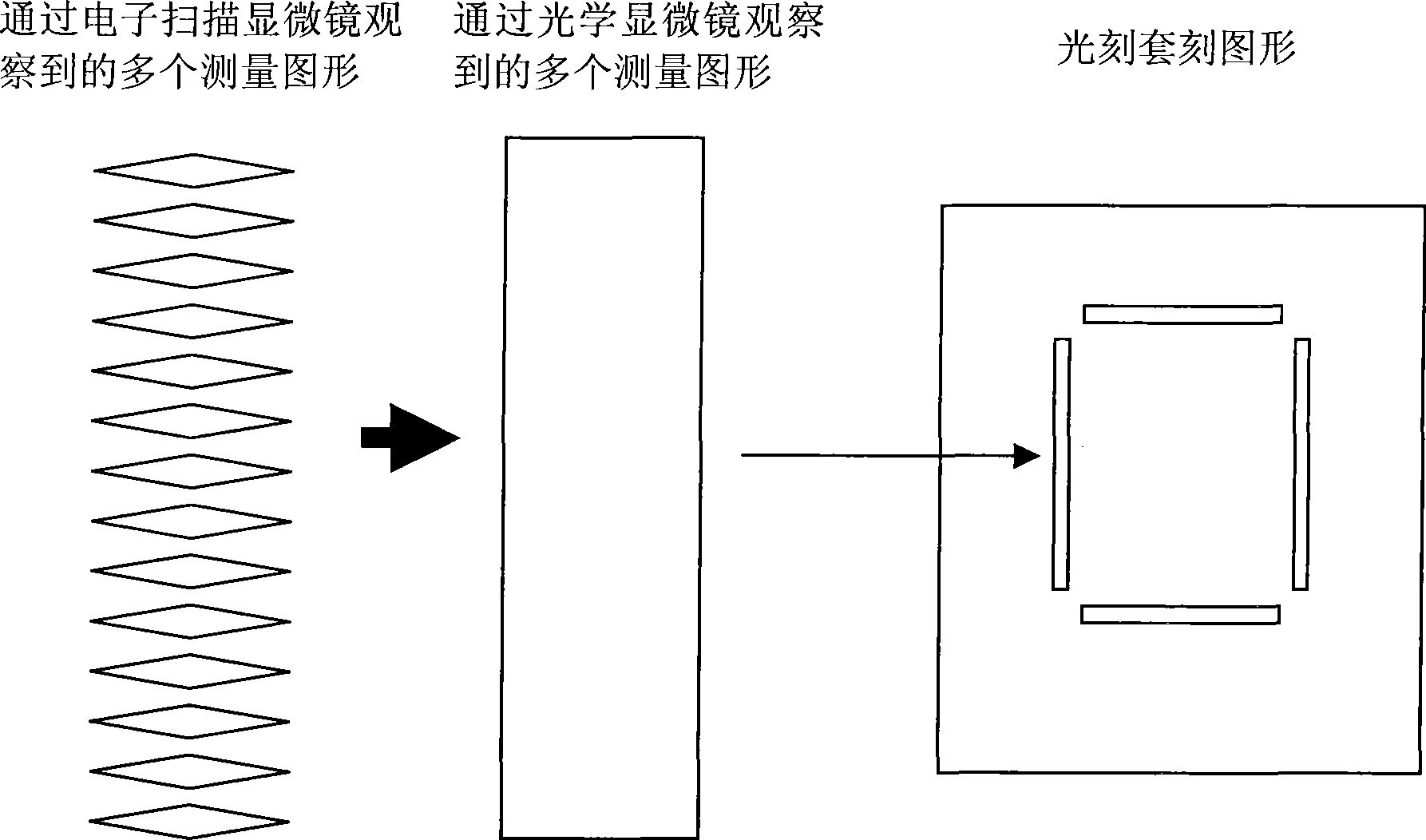

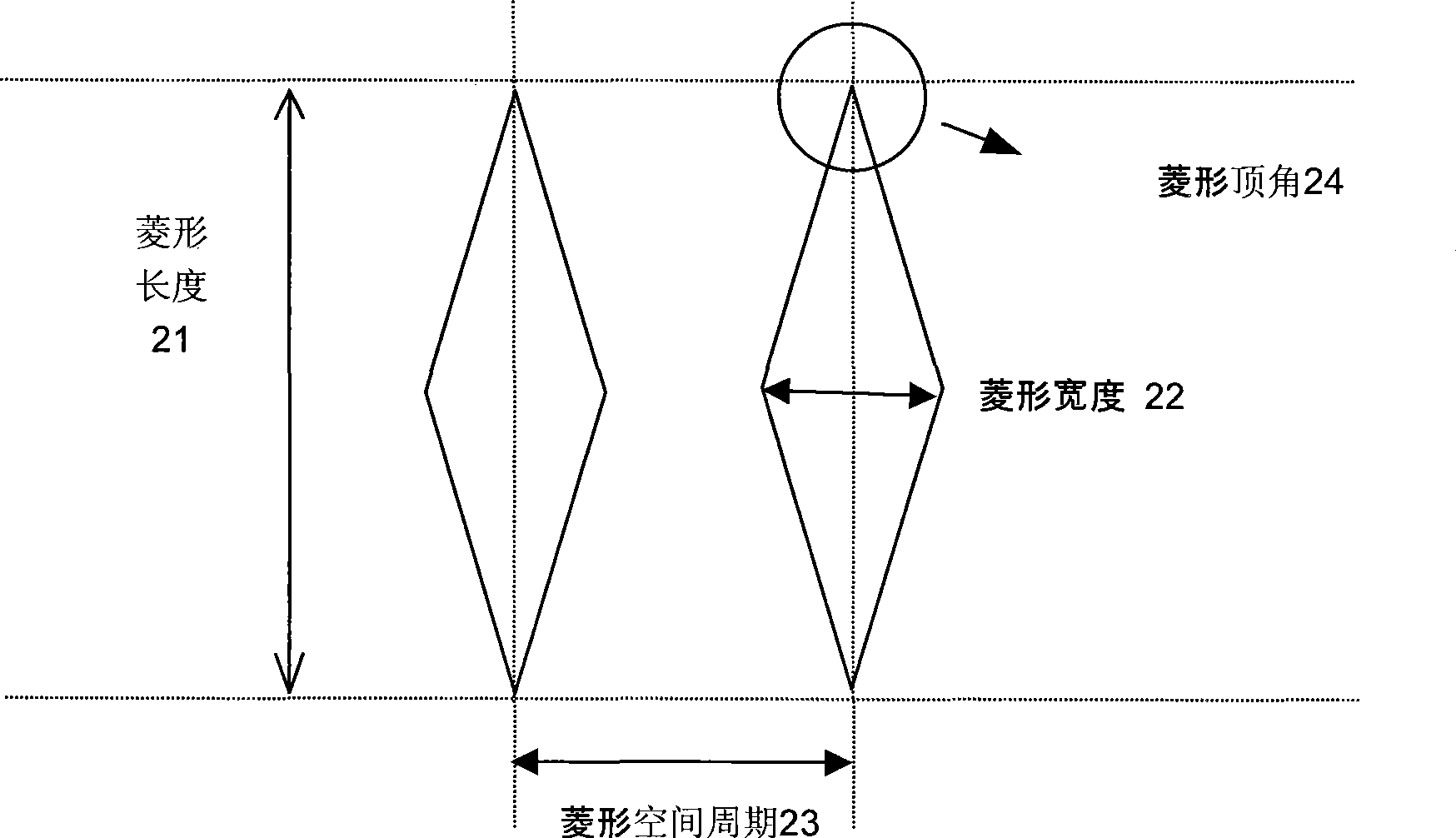

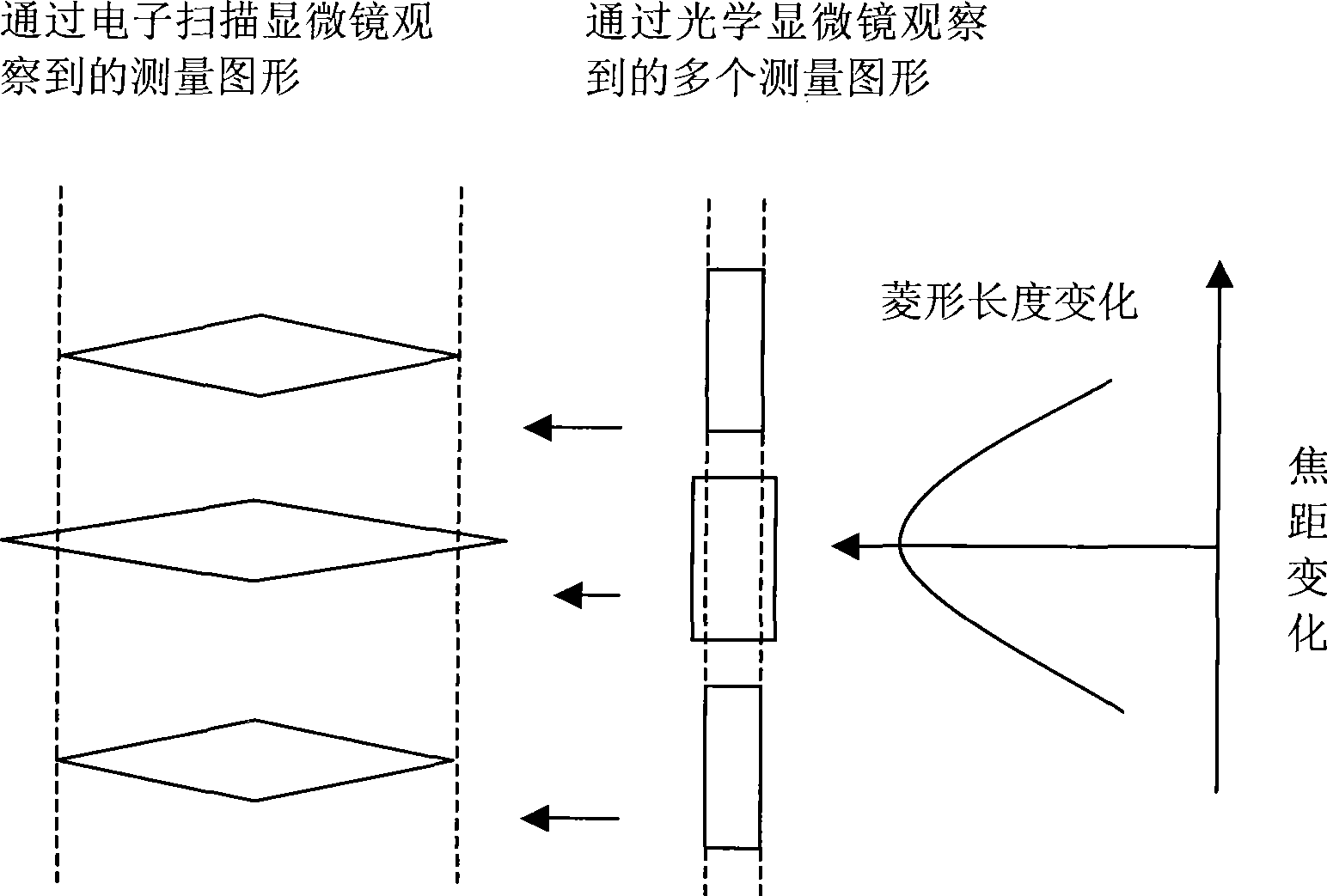

[0012] In the optical proximity effect, there is a so-called LES-Line End Shorting phenomenon: it refers to the phenomenon that due to the diffraction effect of light, the graphics will appear rounded and shortened at both ends of the graphics. The degree of shrinkage of the line end is mainly related to the shape of the graphic, the size of the line width and the change of exposure conditions (including exposure energy and exposure focal length). Compared with ordinary measurement patterns, the phenomenon of measuring line end shrinkage is more sensitive than measuring general critical dimension patterns, so it can better monitor changes in lithography conditions, and this change can be large enough to be measured by an optical microscope, so The present invention mainly utilizes the principle of line end shrinkage, and redesigns the lithographic overlay pattern, so that the optical microscope can be used to measure the lithographic registration accuracy and exposure condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com