Process for recovering nickel ion from biochemical lixivium of laterite nickel mine by using room temperature ion liquid

A room temperature ionic liquid and bioleaching technology, applied in the direction of improving process efficiency, can solve problems such as large consumption of inorganic reagents, many equipment stages, pollution, etc., to improve the comprehensive utilization level, reduce environmental pollution, and improve economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

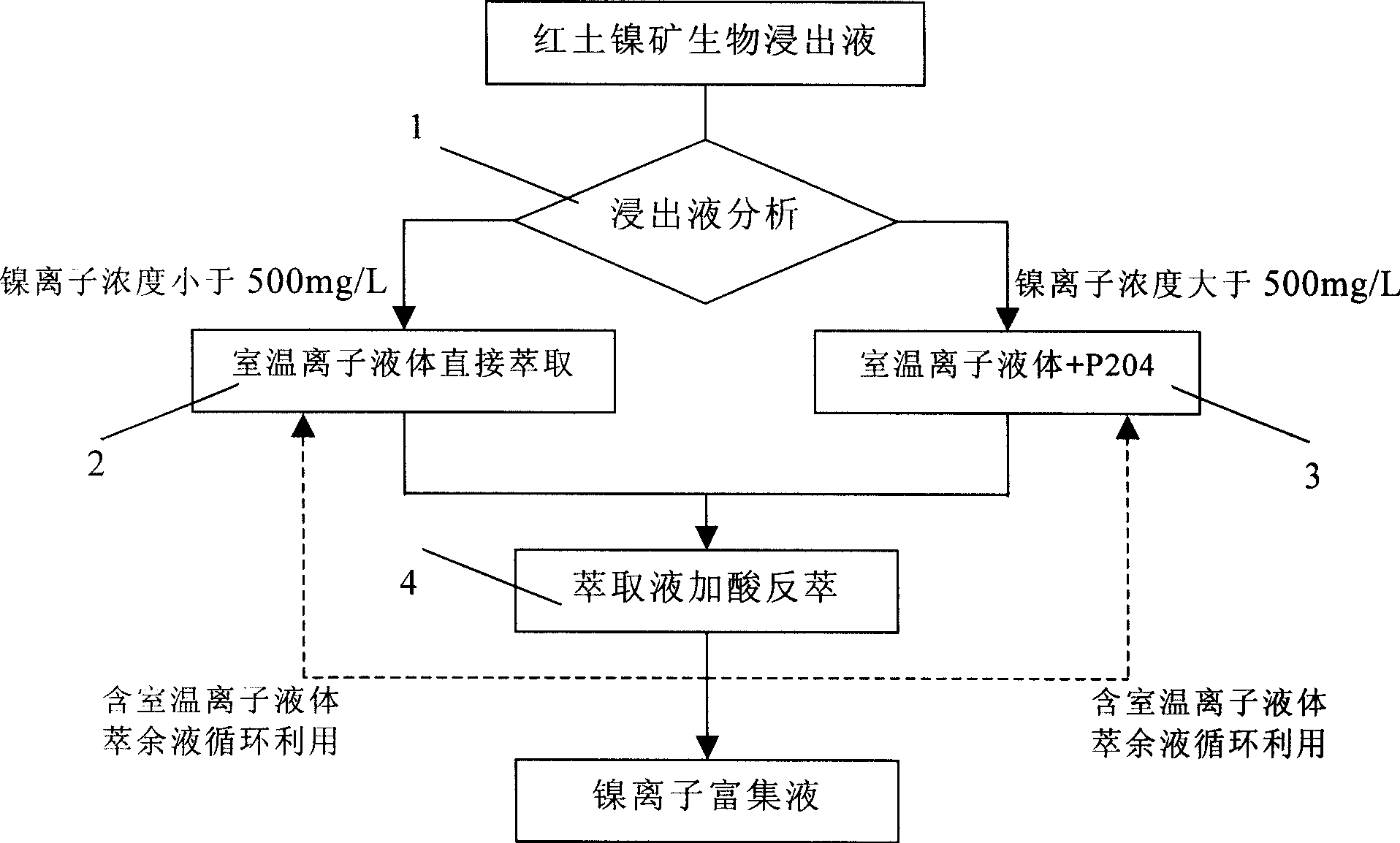

Method used

Image

Examples

Embodiment 1

[0024] For example, a nickel-limonite with a nickel content of 1.32% has a specific ore sample composition as follows:

[0025]

[0026] The mineral adopts the bioleaching method of Aspergillus niger, the pulp concentration is 5%, the acid concentration is 0.2mol / L, the temperature is 35°C, and the rotation speed is 120 rotations / min. The shaking flask test is carried out, and the leaching cycle is 36 hours. The final nickel ion leaching rate was 95.8%, the cobalt ion leaching rate was 68.5%, and the iron ion leaching rate was 43.0%. The nickel ion content in the leach solution is 495mg / L, the cobalt ion content is 15.1mg / L, and the iron ion content is 1970mg / L.

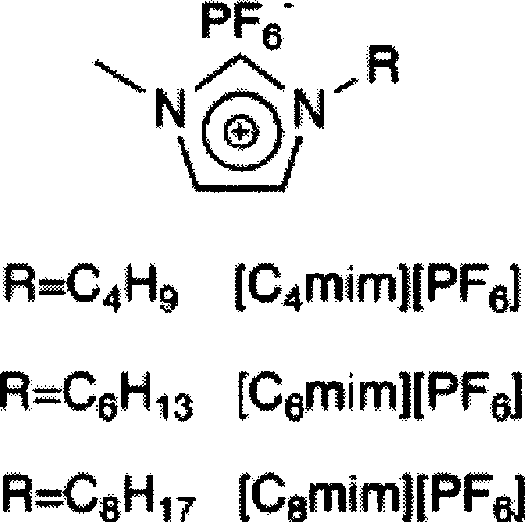

[0027] Add 10ml of room temperature ionic liquid hexafluorophosphate 1-alkyl-3-methylimidazole to each liter of leaching solution, use a shaker to fully shake and stir for 10 minutes, and let stand to separate layers. At this time, the pH value of the solution is 4.0.

[0028] For stripping, add 10ml of 2mol / L hy...

Embodiment 2

[0030] For example, a nickel-limonite with a nickel grade of 1.62%, its specific ore sample composition is as follows:

[0031]

[0032]

[0033] The mineral adopts the Aspergillus niger biological leaching method, the pulp concentration is 5%, the acid concentration is 0.2mol / L, the temperature is 35°C, the rotation speed is 120 rpm, and the shaking flask test is carried out, and the leaching period is 48 hours. The final nickel ion leaching rate was 96.7%, the cobalt ion leaching rate was 68.1%, and the iron ion leaching rate was 46.5%. The nickel ion content in the leach solution is 615.6mg / L, the cobalt ion content is 12.5mg / L, and the iron ion content is 2405.4mg / L.

[0034] Add 15ml of room temperature ionic liquid hexafluorophosphate 1-alkyl-3-methylimidazole to each liter of leaching solution, and at the same time add 1ml of acidic extractant P204, use an oscillator to fully shake and stir for 10 minutes, and let it stand for stratification. At this time, the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com